Hydroponic gardening is cultivating plants without soil, typically in an inert growing medium. “Container culture” is very similar to hydroponics but uses soil, soilless mix, or some other growing medium that is not inert, that is, the growing medium reacts chemically. Hydroponic and container culture gardening are often confused; container culture is often called hydroponics. I believe that the confusion arises for two simple reasons: gardeners who use the term do not understand the difference, and “hydroponics” sounds so much cooler than “container culture”!

Hydroponics has been a buzzword that alludes to higher production and scientific superiority, something special that is new—bigger and better. The misused word hydroponic has also spawned other terms that are invented to distinguish one “unique” product from another. My current favorite terms are ultraponics and fishponics.

Hydroponic gardens are more technical in nature and require precise measurements and monitoring for high performance. Setting up a hydroponic garden is often more expensive and relies most often on man-made, processed chemicals and electrical power.

Hydroponics and container culture are practical for gardeners who cannot grow outdoors and are limited to an indoor or greenhouse space. Changing and working with soil is inconvenient for many apartment and home dwellers. Household electricity seldom fails, and the small gardens can be monitored easily. Indoor gardens are full of life and provide a “breath of fresh air” during long winter months, too.

Greenhouse setups range from inexpensive to expensive, depending upon the degree of sophistication. Greenhouse dynamics—size, heating, cooling, and so forth—can also be more demanding than growing indoors. Outdoor hydroponic gardens are less common and not practical because dirt and dust can easily pollute the garden. Where electricity is not readily available, container gardens can be maintained with battery-powered irrigation controllers and dust and pollutants filtered easily.

Mother plants grow longer and are best suited to large hydroponics or container culture container gardens, which allow room for root development. The mother plant’s root system is easier to control in individual containers, and she is able to produce hundreds of clones during her lifetime. Mother plants need a large root system to take in nutrients in order to keep up with the demanding growth and clone-production schedule.

Hydroponics is not as forgiving as container gardens using soil, soilless mix, coco, and so forth. Soil and soilless mixes not only provide “terra firma” to anchor plants, they also buffer water imbalances and hold air and nutrients well.

Gardens with more components have more to go wrong. Complicated high-tech gardens often require more time and management. Even simple gardens rely on electricity to operate a pump and timer. If the electricity goes out and the pump stops, or even if it only malfunctions, plant growth is impaired. A lack of water for a few hours is long enough to cause damage to plants. Irrigation emitters can clog; pH can climb or plunge, and EC levels can change rapidly. All of these “hydroponic” variables can cause more problems than when growing in container gardens using soil or soilless mix, etc., that provide a buffer or safety zone to hold water and oxygen.

Rule of Thumb: The more parts in a garden, the more there is to malfunction.

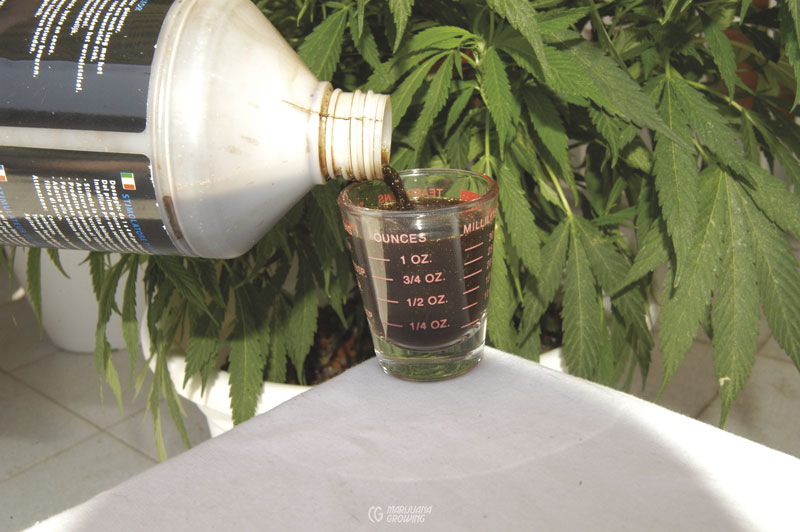

Environmentally conscious gardeners select hydroponic fertilizers with an eye on their budgets. Manufacturers consistently dilute nutrient formulas in water to increase profits—often exponentially. Shipping excess water is expensive, costing more fossil fuel and increasing the garden’s carbon footprint. Purchasing nutrients in a dry form is less expensive and lowers the environmental impact.

Advantages

- no soil necessary

- water can be reused

- complete control of nutrient levels

- clean environment—no dirt!

Disadvantages

- no soil in hydroponics to buffer

problems - disease can spread through entire

crop quickly - large carbon footprint from manufacturing

of components and transport

to stores - water can be recirculated with the

wastes of the plant

Contrary to popular belief, hydroponically grown cannabis does not grow faster or produce heavier harvests. Scientific research (not funded by commercial interests) since the mid 1950s shows no significant difference between container-grown crops in soil, soilless mix, etc., and hydroponically grown crops. Work by D. R. Hoagland and D. I. Arnon in the first half of last century failed to prove that there was an increase in potential yields from growing hydroponically. They described the first nutrient solution to use for hydroponics, still in use today. To date no one has been able to refute this, and it remains a referenced work.

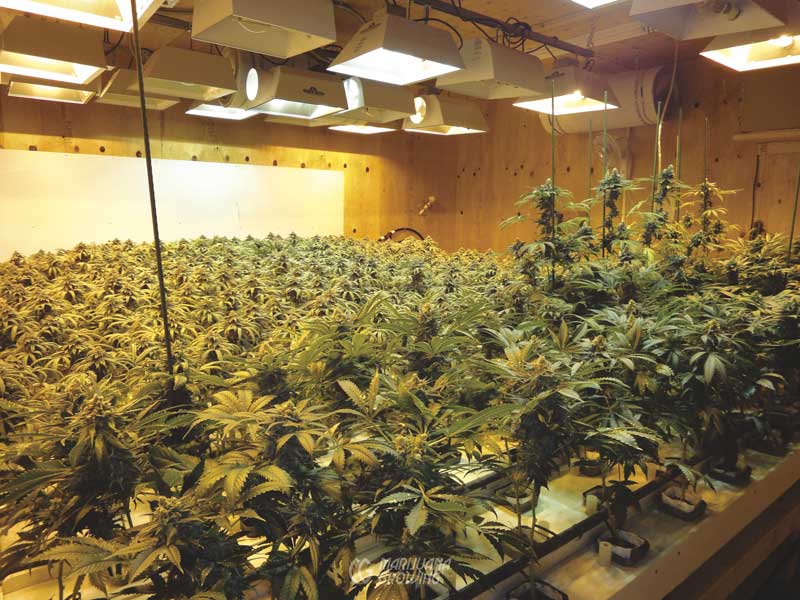

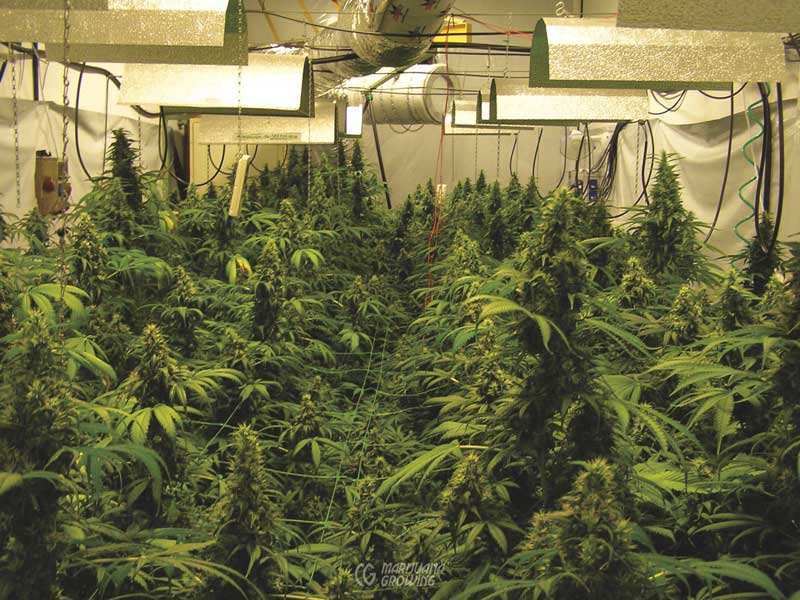

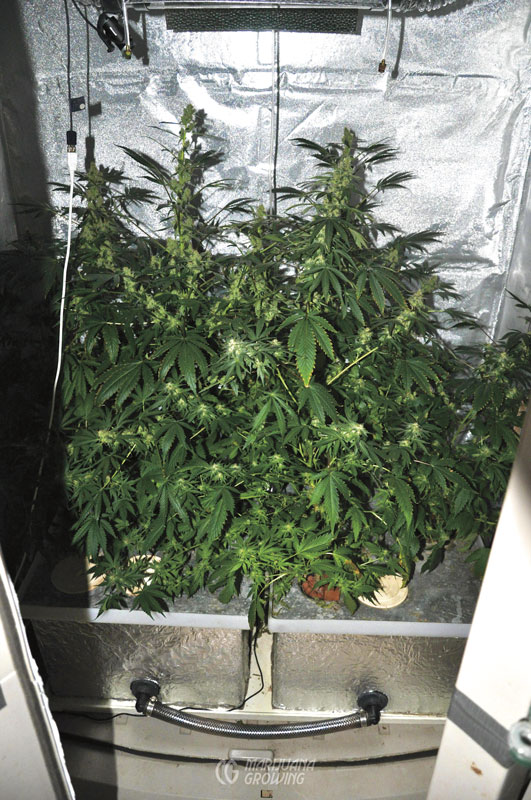

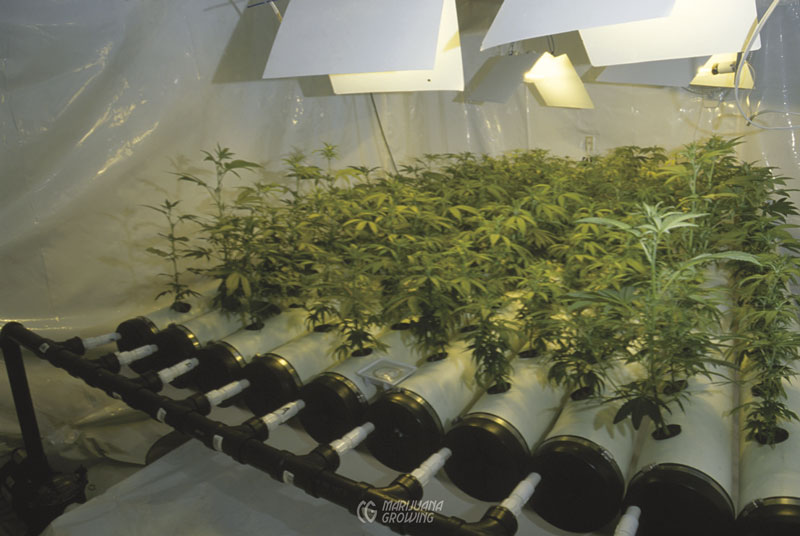

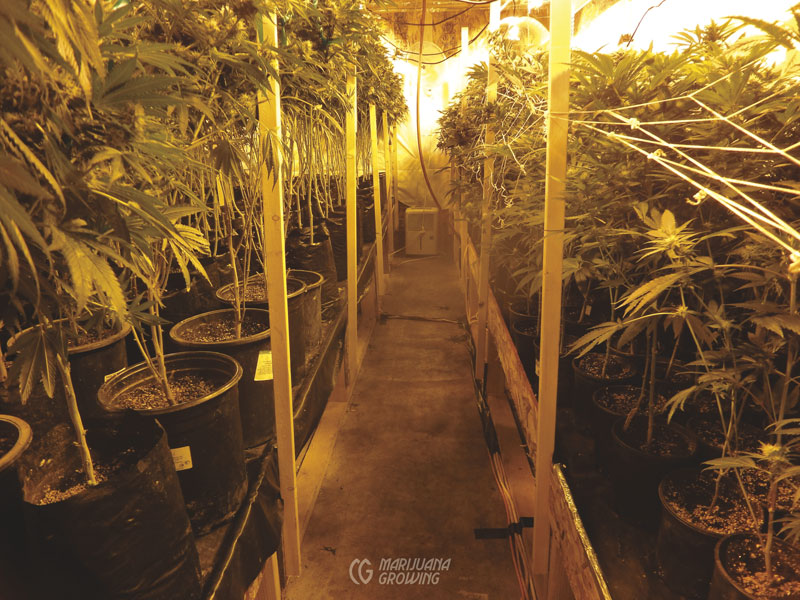

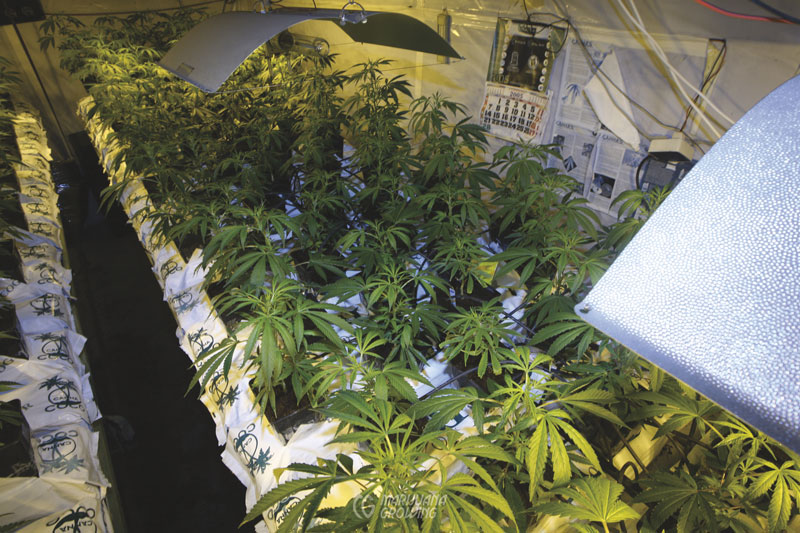

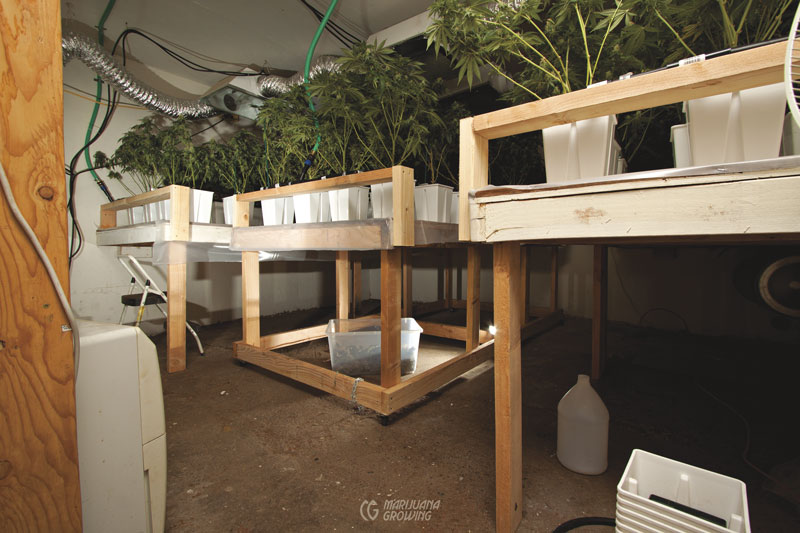

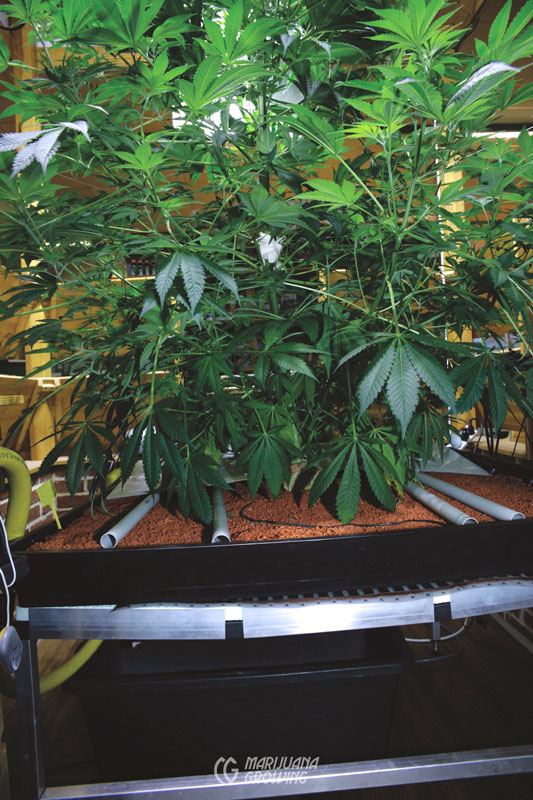

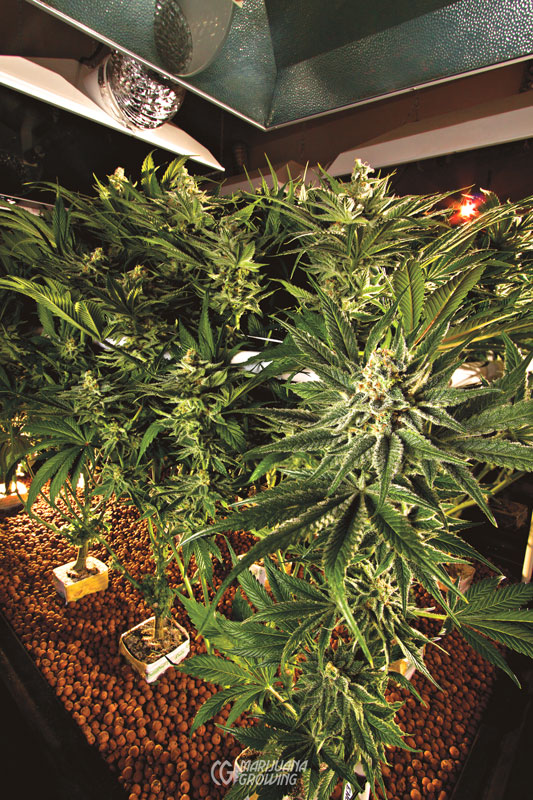

A properly managed rockwool top-feed garden such as this one, from Trichome Technologies, is super productive.

Healthy container gardens like this one are irrigated automatically. Penetrating the foliage in this garden is difficult and could break branches.

A small hoop greenhouse like this is easy to manage when growing medical cannabis in individual containers.

Air root–pruning containers are available that encourage more dense root growth.

These little seedlings are being hardened-off to transplant outdoors. They are watered from the top with a water wand that has an aerating nozzle.

Container Culture and Hydroponics

Solution Culture

Cannabis grown in hydroponic solution culture gardens does not use growing medium. However, plants in some gardens are started in a small net pot in a handful of substrate. Examples of solution culture include aeroponics, bubbleponics, deep water culture (DWC), deep flow technique (DFT), nutrient film technique (NFT), and raft solution culture. These gardens require an electric pump that must function 24 hours a day to operate nutrient-solution drippers, emitters, air (oxygen) diffusers, misting nozzles, often with a good filter to ensure debris-free solution.

Media Culture

Media-based hydroponics uses an inert substrate such as rockwool or expanded clay pellets. The inert substrate does not react chemically with nutrients. Container culture employs substrate such as soilless mix, or coco coir that is not inert and will react chemically with the nutrient solution. The substrate, whether inert or not, serves multiple functions— to anchor plants and to hold air, water, and nutrients for root uptake. The media also holds precious oxygen that is essential for rapid nutrient uptake. Ideal growing mediums hold plenty of air (oxygen) and nutrient solution at the same time. Soilless mix and coconut coir are two of the most popular growing mediums used in container culture. Rockwool and expanded clay are the most common substrates found in hydroponics. Nutrient solution is delivered to the media via flood-and-drain, top-feed, or passive wicking that relies on capillary action.

In container culture and many types of hydroponics, the supply of oxygen in growing media can be maximized, which in turn allows properly grown plants with healthy roots to take in peak levels of nutrients. However, in “solution culture” it is very difficult, if not impossible, to consistently achieve the same oxygen levels as in properly aerated growing media. Fine-tuned nutrient solutions can steer plants to grow less leafy vegetative foliage and more dense flower buds.

Properly mixed and applied hydroponic nutrients—chemical salts diluted in water—are able to supply exact element levels so that roots have access to them and the possibility of taking them in at maximum capacity. Aerated nutrient solution is absorbed, wicked up from the growing medium, or it passes over roots, later draining off. The oxygen in solution, around roots or trapped in the soilless medium, speeds nutrient uptake. Organic nutrients—natural elements and compounds—are more difficult to control in container culture than their chemical counterparts. In nature these nutrients are often bound in complex living chemical compounds that are difficult to measure accurately.

Regardless of the nutrient-solution application method, nutrient solutions are either run-to-waste (RTW) and not reused, or they are recirculated and used again and again rather than being discarded after one use. Recirculating systems have the added complication of concentrating the nutrient solution and the accumulation of plant wastes— broken roots, leaves, and so forth.

Nutrients are diluted in water in a “soil solution” or in an inert medium “hydroponic solution.” In soil, soilless mix, coco coir, etc., there is a naturally occurring ratio of oxygen to nutrient solution. However in hydroponics using rockwool, expanded clay pellets, or other inert ingredients, this ratio must be “manufactured.” And in any hydroponic garden where roots are covered with nutrient solution all the time, oxygen is contingent upon oxygenating the solution artificially, and it is very easy to screw it up.

Oxygen is pulled or moves into the soil, soilless mix, etc., or dissolves hydroponic solution where it can move into the roots. If the roots dry out, oxygen movement becomes restricted, especially if it drops below the critical oxygen pressure (COP) (amount of O2 dissolved into solution). In cannabis, COP is the point where respiration is first slowed from a lack of oxygen at about 20 mg/L*. The root tips are very active and have relatively high energy requirements, almost as high as humans but below the COP this activity slows.

*Plant Physiology, 3rd ed., by Lincoln Taiz and Eduardo Zeiger, (Sunderland, MA: Sinauer Associates, Inc., 2002).

At maximum levels of stirring, the amount of dissolved oxygen will be barely enough to keep up with O2 utilization, and to get as close to 60 ppm as possible, oxygen must be diffused into the solution, typically with an electric air pump.

In the older root zones this lack of oxygen becomes an issue earlier at lower rates. Since their uptake is reduced to 10 percent of the tips’ uptake, the cores can become anoxic (severely deficient in oxygen) or hypoxic (oxygen deficiency causing a very strong drive to correct the deficiency), killing the roots or affecting performance. The best way to achieve maximum aeration is not by growing in deep water that covers roots all the time, but by allowing dry time for the roots; because at this time, the solution on the root surface is still dissolving O2 at higher levels when the air moves in and the water is gone. No extra aeration is needed other than stirring the nutrient reservoir. The amounts of oxygen needed by the root system will be absorbed at the root surface as well.

Solution Culture

aeroponics

bubbleponics

deep water culture (DWC)

deep flow technique (DFT)

nutrient film technique (NFT)

raft solution culture—passive

Media Culture

ebb-and-flow (flood-and-drain)

hydro-organic

top-feed—containers and slabs

run-to-waste (RTW)

wick—passive

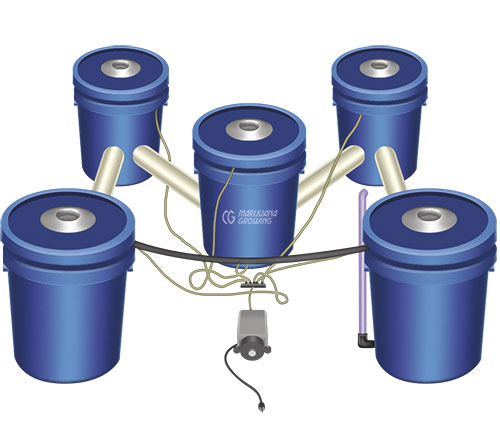

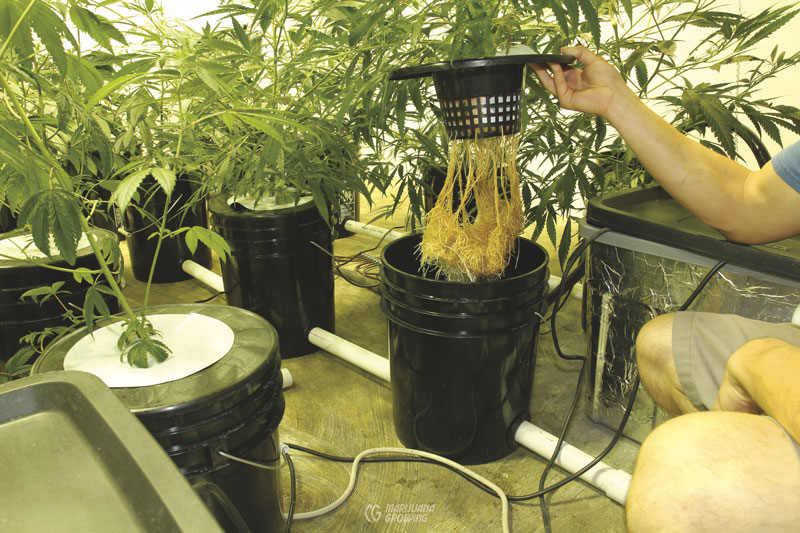

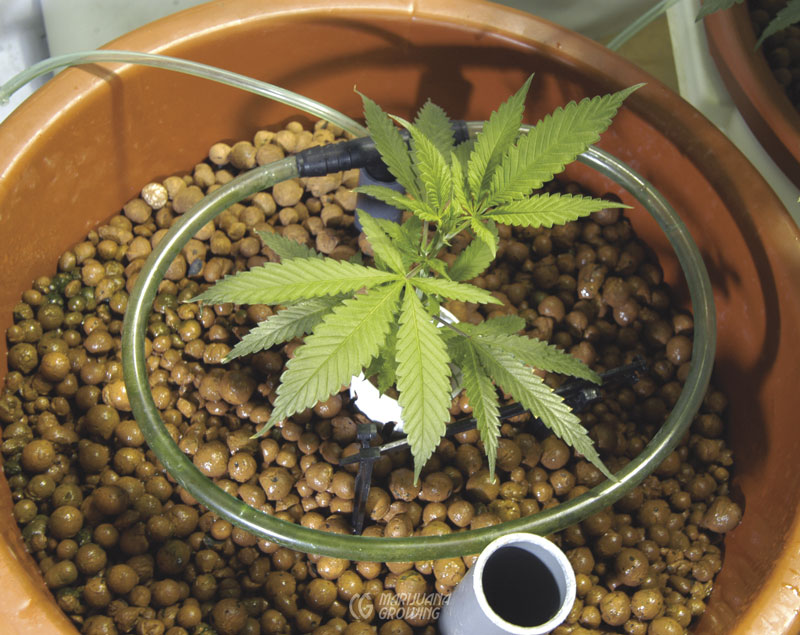

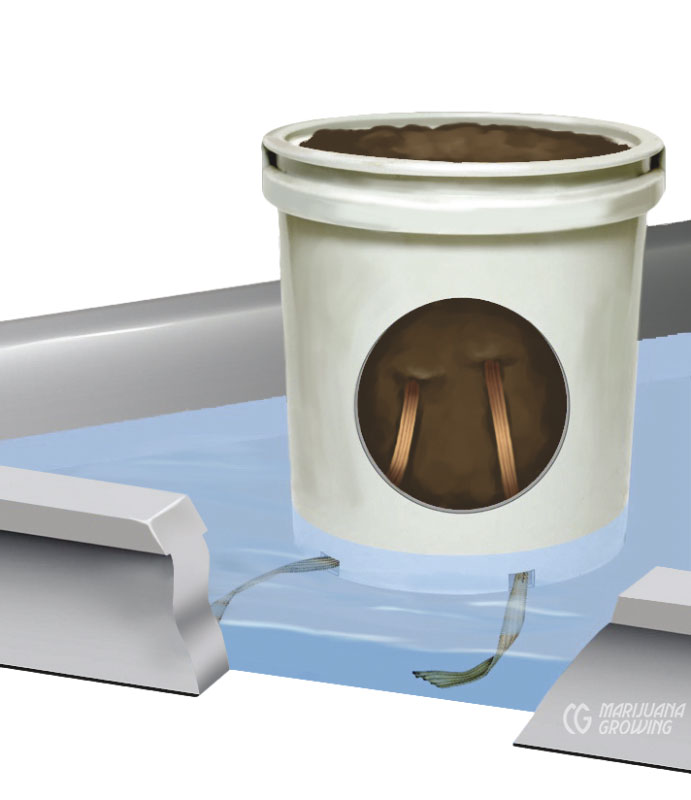

This hydroponic garden is made from 5-gallon (18.9 L) containers connected together with half-inch (1.3 cm) tubing.

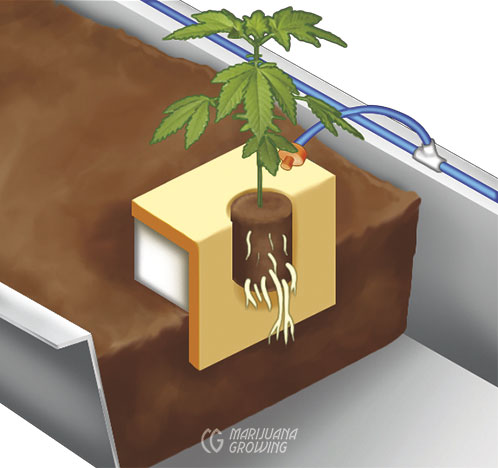

Nutrient solution floods into the garden bed to irrigate. The nutrient solution pulls more oxygen into the moist rockwool cubes when it drains.

Aeroponic Gardens

Aeroponic gardens are true to their name. Plants grow in a chamber of air and nutrients. Roots are suspended in a dark growth chamber without growing medium and continually or at regular intervals misted with a fine oxygen-rich nutrient solution. Medical cannabis gardeners use efficient aeroponic gardens to root cuttings, but seldom for vegetative or flowering. Since cuttings grow with no media attached, they can be transplanted into solution or media hydroponic gardens as well as soil. However, damage to minuscule root hairs is impossible to avoid.

The origin of aeroponics dates back to the first half of the 20th century; the first patent was issued in 1985 to Richard Stoner. In fact, the first cannabis aeroponic clone garden that I saw was in the mid-1980s, and it was very similar to Stoner’s. It was homemade. Aeroponics makes control of conditions in the root zone much easier in hot climates than with conventional hydroponics. Often fatal nutrient-solution stagnation, waterlogging, and oxygen starvation are easier to control with aeroponics. The temperature inside the root chamber is easy to control, which is essential for avoiding pathogens and keeping adequate oxygen available. Properly designed and maintained, an aeroponic clone garden will yield a profuse, strong, and healthy root system.

Root systems of small seedlings and clones thrive in net pots specifically designed for aeroponic gardens. Clone roots strike (initiate) and seedling roots grow down from net pots into the dark, humid, nutrient-and-oxygen-rich environment. Regular misting in the 100 percent humid atmosphere prevents tender clones from drying out, all the while speeding root development. The totally dark chamber stops algae growth as root growth thrives.

Solution droplets of less than 30 microns tend to form a fog that humidifies the air but is not easily absorbed by roots. Larger, 30- to 100-micron droplets are more readily absorbed by roots. Droplets of greater than 100 microns precipitate from the air too quickly for root absorption.

The opening on a 30-micron (0.018 inch [0.046 mm]) nozzle is very small, clogs easily, and must be kept super clean. Use reverse osmosis water and low nutrient levels (about 10 percent strength), and maintain pump pressure to keep nozzles free of debris. Using a pre-pump filter and inline filter helps to remove debris and keep nozzles clean. Avoid or heavily filter any additives or nutrients containing organic matter.

Both continual and intermittent operation work well and achieve the same results—as long as the proper environment is maintained. Forcing solution through a 30-micron nozzle requires more pressure and a stronger, more expensive fitting and pump, which are also more costly to operate. If growing in large aeroponic gardens, electricity consumption becomes expensive; intermittent misting will save money. Use a timer that will cycle mist for one to two minutes, and then turn off for up to five minutes, 24 hours a day, to save resources.

Temperatures are easy to control in any climate in an insulated root chamber.

Simply heat or cool the nutrient solution before misting roots to bring the root zone temperature to the desired level. Avoid disease by keeping temperatures below 72°F (22°C) and regularly inspect roots for signs of discoloration, rot, and lack of fine root hairs.

Simple, small aeroponic gardens that pump nutrient solution up from the reservoir located below the root chamber are best suited to clone rooting and seedling growth. These gardens are less expensive than larger gardens with a separate reservoir and rooting chamber designed to grow mature plants. Gardens with a separate reservoir are less likely to clog as mature roots grow into the nutrient solution.

Aeroponic gardens are easy to construct, but fine-tuning a homemade unit could kill a few crops of clones before success is achieved. The basics are simple: the unit must be light- and watertight, and mist from nozzles must be of the proper size and delivered under adequate pressure.

EC and pH considerations for aeroponic gardens are the same as for any hydroponic garden. But aeroponic gardens require greater attention to detail. There is no growing medium to act as a water/ nutrient bank, and if the electricity goes out, the pump fails, or the nozzles clog, roots will soon dry out, killing tender root hairs. The whole root begins to die, starting at the tip.

There are several variations of aeroponic gardens including the Ein Gedi method, aero-hydroponics, and air-dynaponics.

Aeroponic gardens that throw 30- to 50-micron droplets promote fast root growth.

Root growth is phenomenal in an aeroponic clone machine.

The aeroponic clone garden on the right is in front of medical cannabis prescriptions that certify patients.

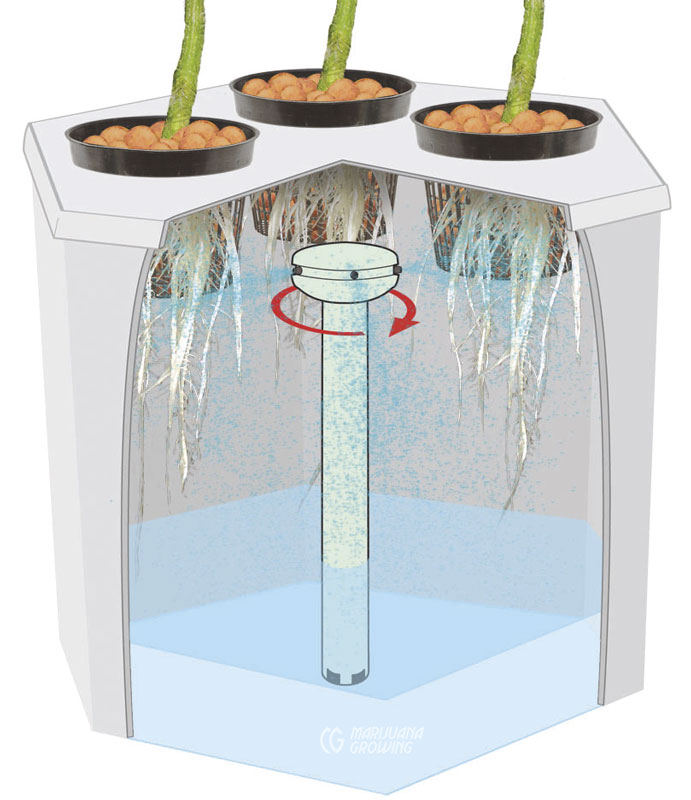

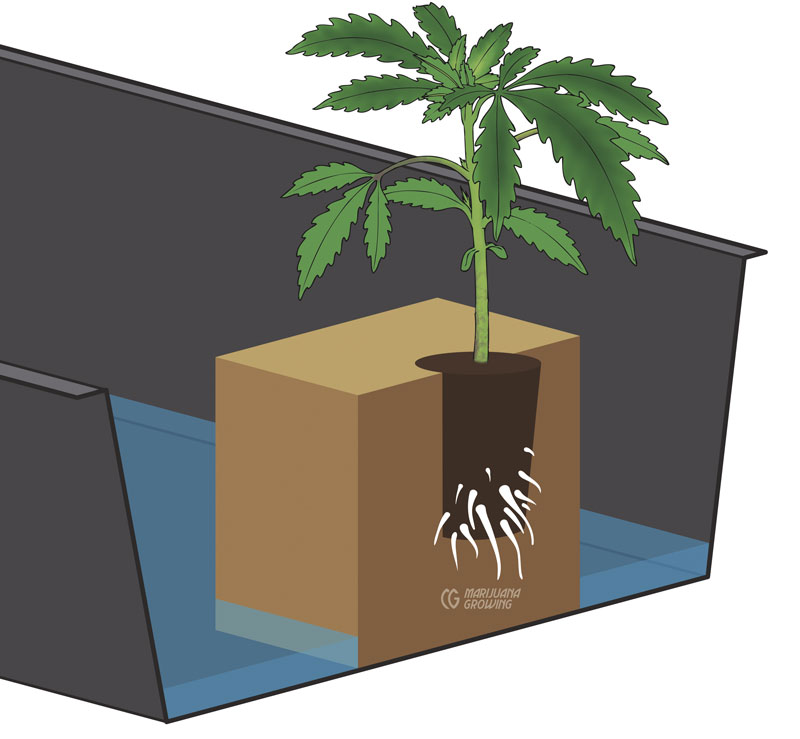

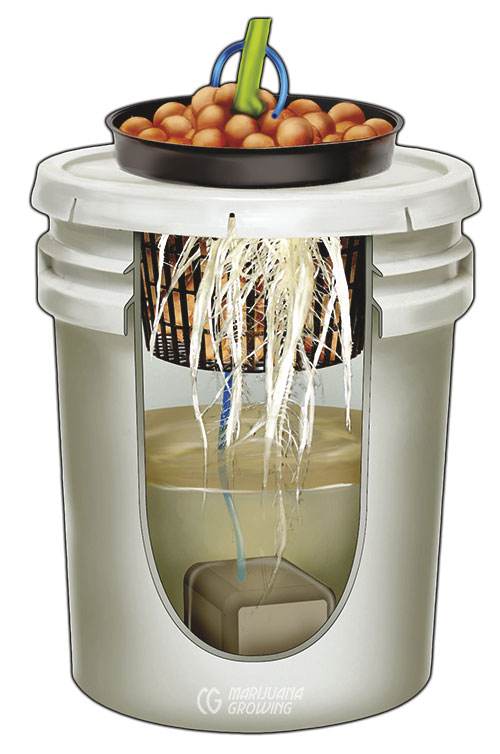

Deep Water Culture (DWC)

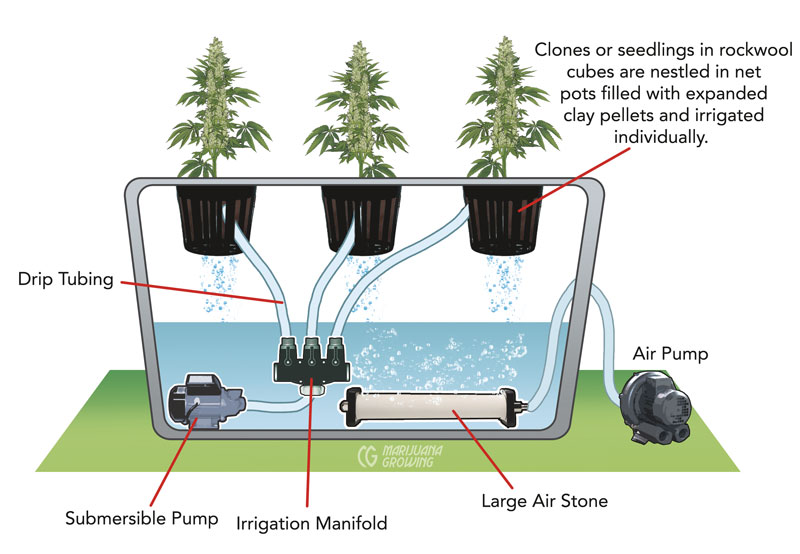

Deep water culture (DWC) is simple and inexpensive. This low-maintenance method is typically employed by casual medical gardeners who want to grow a few plants in a small area. Seedlings and clones are held in net pots full of expanded clay pellets, rockwool, or a similar growing medium. Six-inch (15.3 cm) net pots are most common for single 5-gallon (18.9 L) containers. Smaller 2-inch (5.1 cm) net pots are often used for multiple plants in the same container. The net pots are nestled in a plastic lid that covers the reservoir. Roots dangle into a somewhat dilute (75 percent concentration) nutrient solution that is aerated with an air stone and pump. Feeder roots absorb nutrients and water from the solution in the oxygenated environment. The simple design requires no timer for the air pump that runs 24 hours a day.

A closed DWC system is completely self-contained.

Closed or self-contained, recirculating DWC gardens stand alone with the reservoir directly under the net pot containing the plant. Closed gardens are perfect for gardeners who want to grow a few plants. The gardens also work well for large mother plants and to contain any waterborne diseases. The pH, EC, and solution must be checked for each individual reservoir. Nutrients, pH up, pH down, and any other additives must also be added to each container.

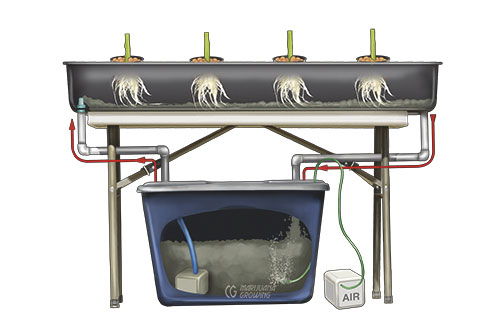

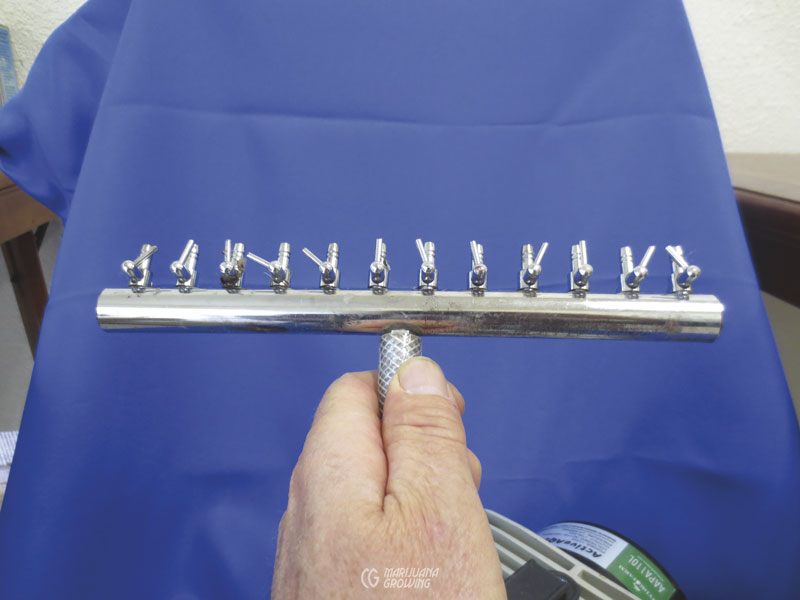

Multi-unit recirculating gardens are more complex, with a central reservoir connected by tubing to several container/ reservoirs. A central air pump aerates nutrient solution in each container via a manifold connected to air tubes that are in turn connected to an oxygen diffuser in each container. Although the garden has more complex plumbing, the pH, EC, nutrients, and other additives can be controlled from a central reservoir.

The levels of all reservoirs—central and all container/reservoirs—seeks the same solution level. Simply check the reservoir level to learn the level of all the others. Use a Mariotte’s bottle or a float valve to automatically maintain the solution level.

The nutrient solution flows to all containers in this recirculating DWC garden.

The air pump must supply each 5-gallon (18.9 L) reservoir with at least 1.3 gallons per minute (4.9 LPM) to ensure that adequate oxygen is available to roots. Less than this amount will deprive roots of oxygen, slow nutrient uptake, and open the door to cultural problems, pests, and diseases.

Set the air pump above the reservoir so that water will not siphon back through the air pump and destroy it if electricity goes out or the pump malfunctions.

Caution! Do not keep air pumps inside CO2-rich garden rooms or greenhouses, or the extra CO2 will drive the pH downward as the conjugate acid of the carbonate base or upward as the conjugate base of the carboxyl acid. (It really depends on many factors.)

This plant is irrigated from above. The rockwool holds the plant, and the roots grow down into the water about an inch (2.5 cm) below the rockwool. (MF)

Roots are bathed in nutrient-rich aerated solution in DWC. (MF)

Bubbleponics and Raft or Pond Culture

Bubbleponics and raft or pond culture, are a variation of DWC. In bubbleponics the nutrient solution is delivered via top-feed nozzles or spaghetti tubes to a small amount of growing medium that holds the plant in place. The nutrient solution is allowed to percolate down through the growing medium before falling back into the aerated reservoir and recirculated. Bubbleponic gardens require two pumps, one to deliver nutrient solution, and an air pump attached to an air stone or other diffuser to aerate the nutrient solution.

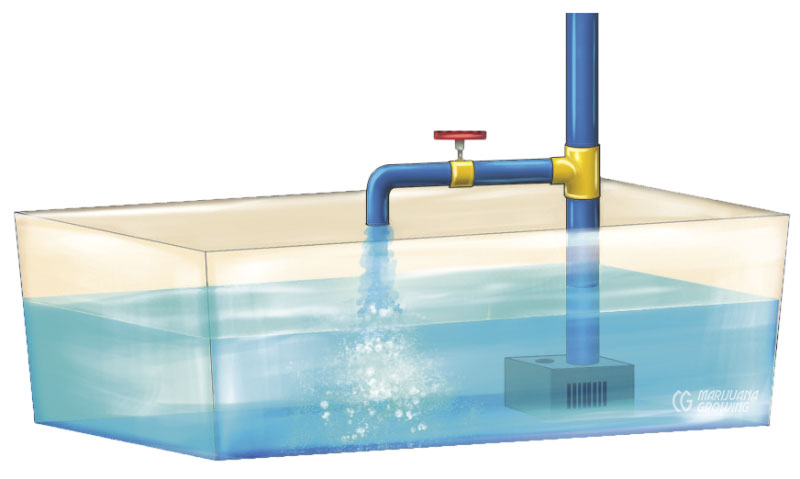

A (submersible) pump lifts nutrient solution to the top of a discharge tube connected to a top-feed irrigation system. Nutrient solution is delivered to individual plants and cascades down, wetting roots and splashing into the (self-contained) reservoir below, which in turn increases dissolved oxygen in the solution.

In raft or pond solution culture, plants are placed in a sheet of buoyant plastic that is floated on the surface of the nutrient solution. Roots are always submerged in artificially aerated nutrient solution.

Transplant Clones or Seedlings

Fill with nutrient solution until the bottom inch of the 6-inch (15.2 cm) net pot is covered. Avoid filling to the level of the stem to prevent stem rot and other diseases. Hand irrigation may be necessary for the first few days if capillary action does not wick nutrients upward to roots. After the roots grow through the net pot, lower the level of the nutrient solution to about 2 inches (5.1 cm) below the net pot. An external dark-green translucent “drain tube” on reservoirs will indicate solution level.

The nutrient solution tends to stay the same temperature as the room unless it is cooled slightly. Insulating and placing it on a cold floor will help keep solution cool. Always aim for the ideal nutrient temperature range 55°F–65°F (12.8°C–18.3°C) to prevent disease and increase dissolved oxygen (DO) in solution. Change nutrient solution at the first sign or suspicion of problems— solution discoloration, pH fluctuation, or a change in EC.

Top off nutrient solution with plain water daily. Change the reservoir every week to ensure proper nutrient levels. Changing the solution can be a bit of a job. If the reservoir has a drain plug, the solution can be drained and replaced weekly without removing the plant. This will help minimize salt buildup too. With no drain plug, the plant has to be removed from the container/reservoir and placed in another container. The air stone must be removed and the solution dumped. Dump old nutrient solution that is full of nitrates, sulfates, phosphates, and so forth, in the outdoor garden rather than down household drains. The container/ reservoir must be completely cleaned and refilled with fresh nutrient solution. Many deep water culturists dilute nutrient solution to 75 percent strength to safeguard against overdose. Always run EC at lower levels in DWC gardens. Check with fertilizer manufacturers for recommendations.

Outdoors, the container/reservoir must be shielded or insulated so that direct sunlight does not cause the temperature inside to climb beyond 70°F (21.1°C). Outdoor gardens also need an overflow drainage hole in the side of the reservoir to prevent rainwater from diluting solution or causing it to overflow.

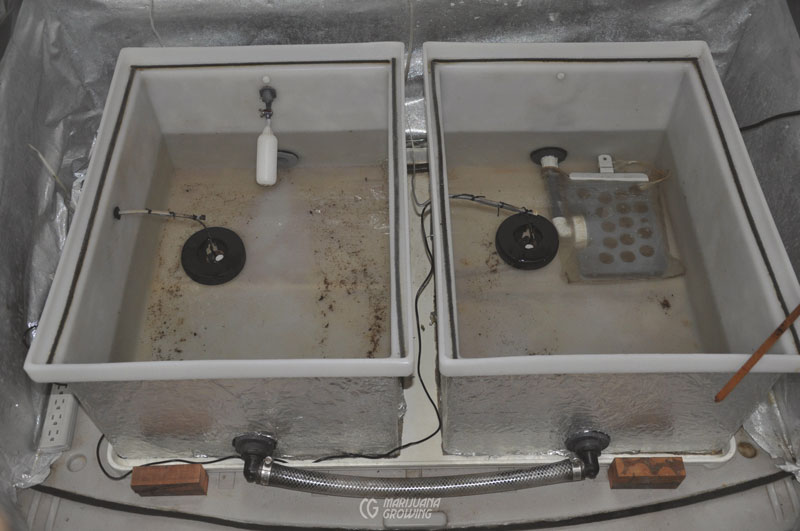

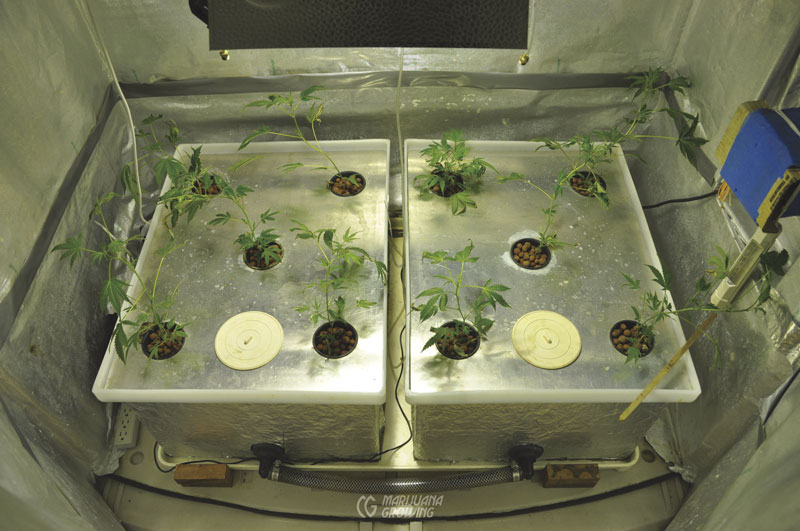

The grow tanks are set up and filled with nutrient solution.

The little plants are set in the beds on top in net pots full of expanded clay pellets. Roots hang down into the aerated solution.

One week later, the same clones look a lot stronger and healthier, but they have not completely recovered from the transplanting.

Two weeks later, the garden looks like it is thriving, and plants have put on growth.

The harvest from a small garden is small but enough to sustain many medical cannabis gardeners until the next crop.

Nutrient Film Technique (NFT)

Deep Flow Technique (DFT)

Deep flow technique is similar to NFT except roots in gulleys are submerged with 1 to 2 inches (2.5–5.1 cm) of nutrient solution. Make sure nutrient solution is well aerated and flows quickly enough through tubes and gulleys to maintain adequate oxygen levels for roots. Check the temperature in different parts of the tubes to ensure that it does not climb above 70°F (21.1°C) and holds at least 8 ppm of dissolved oxygen.

The nutrient film technique (NFT) was developed by Allen Cooper from England in the 1960s. Cooper introduced the garden to the world in his book, The ABC of NFT. NFT hydroponic gardens are most suitable for short-term crops with a compact root system including predominantly indica and ruderalis varieties that are harvested in 3 to 4 months. When grown too long, extensive cannabis root systems tend to block solution flow in gulleys.

The system supplies aerated nutrient solution to plants with roots held in gulleys. Seedlings or cuttings in small net pots full of substrate with strong root systems are placed on capillary matting located on the bottom of a covered channel or gulley. Capillary matting takes the place of a growing medium, stabilizes nutrient-solution flow, and holds roots in place. The nutrient flow can also be intermittent when used with a base like sand or perlite. Plastic tubes or sleeves are available that can be filled and laid on the ground as well. Well-aerated nutrient solution flows down the gulley, over and around the roots, and back to the reservoir. Irrigation is constant—24 hours a day. Roots receive plenty of oxygen and are able to absorb a maximum of nutrient solution. Gulleys must have the proper incline, volume, and flow of nutrient solution for a successful crop. NFT gardens must be fine-tuned to perform well.

Gulleys or channels are covered to keep humidity high in the root zone. A white exterior reflects light and the interior can be painted black to keep roots in the dark and stop algae growth. Roots that are completely submerged have less access to oxygen in the air compared to oxygen available in the nutrient solution. Maintain a thin layer, 0.4 to 0.8 inches (10.2–20.3 mm) of nutrient solution to allow for adequate air absorption. Roots submerged in turbulently flowing nutrient solution are intermittently exposed to humid air.

Capillary matting under rockwool cubes holds roots, air, and nutrient solution.

Nutrient solution is pumped from the reservoir into gulleys via a manifold and tubing at the upper end. The table is set up on a slope with a 1:50 fall in 12 feet. For example, if the bed is 50 inches (127 cm) long, the fall is 1 inch in 50 inches, or 1 centimeter in 50 centimeters. The incline helps solution flow that in turn compensates for surface, while avoiding both accumulation and waterlogging the roots. As a general guide, flow rate should be 0.5 GPM (1.9 LPM) at planting. After plants are established, flow rates for each gulley should be at least 0.25 GPM (0.9 LPM) and can be a maximum of twice this amount. Beyond this, extreme nutrient uptake problems can occur.

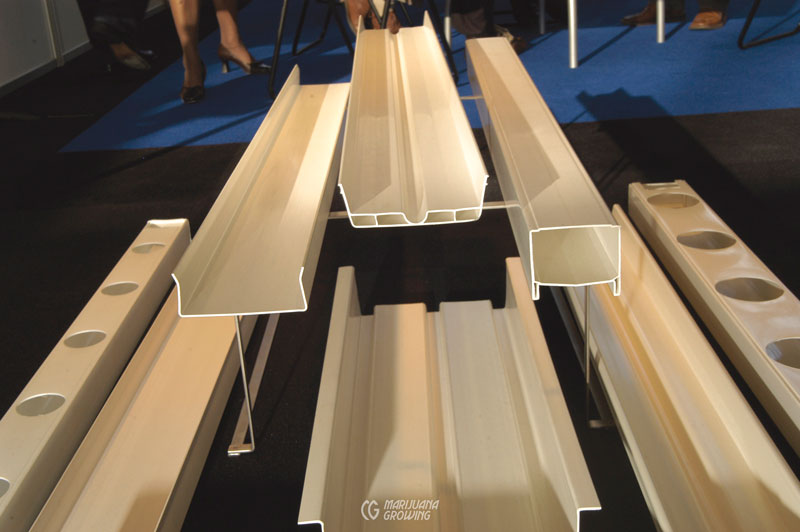

Gulley length should be less than 40 feet (12.2 m) to avoid slow growth. Oxygen in solution is frequently adequate, but nitrogen can become depleted at the low end of gulleys. Longer runs require meticulous leveling of gulleys to avoid high and low spots that expose roots too much or cause puddles. Double reinforced bottoms make gulleys durable and rigid when supporting large plants, large root systems, and large volumes of nutrient solution. Some NFT gulleys have ribs below to provide support and prevent warping and movement. The ribs also function as drainage channels and direct nutrient solution evenly along the bottom of the gulley.

A good filter will prevent debris from blocking gulleys, supply tubes, and pumps. NFT gardens have very little buffering against interruptions in the flow caused by plumbing blockages, power outages, and so on. In the absence of a growing medium, roots must be kept perfectly moist by the nutrient solution at all times. If a pump fails, roots dry and die. If the garden dries out for a day or longer, small feeder roots will die and grave consequences will result. Problems occur quickly in NFT gardens, and decisive corrective action is necessary. This garden is not recommended for new growers.

Place a filter on the pipe that returns nutrient solution to keep the reservoir clean. Organic garden filters may clog and need cleaning more often. Use 0.25-inch (6.35 mm) microtube feeders so that small chunks of debris pass right through. Filters on pressurized lines create backpressure, which causes pumps to strain and pump efficiency to diminish, consequently a more powerful pump is necessary.

NFT gardens are very easy to clean and lay out after each crop. However, only gardeners with several years of experience should try an NFT garden.

A big, healthy, white root system is a sign that there is enough dissolved oxygen in solution. Note that some of these roots are discolored and only a few roots are strong and white. This root system does not receive enough dissolved oxygen. (MF)

Nutrient solution in the tubes is kept about 6 inches (15.2 cm) deep. The nutrient solution is constantly moving and being aerated as it moves around roots.

NFT gardens were more popular 15 years ago than they are today.

Transplant Clones or Seedlings, and Grow

Start clones and seedlings in small 2-inch (5.1 cm) net pots full of rockwool or substrate that does not shed debris to clog the irrigation system. Or cut large holes in small pots for an inexpensive alternative to net pots. The small pots must permit unrestricted root expansion when growing into gulleys. Do not grow clones and seedlings in soil or media that will shed debris. And do not try to wash media from root mass with cold water. This will severely damage roots, compound transplant shock, and slow their establishment in gulleys. Plants started in soil or messy substrate should be lightly shaken to remove “debris” and then be transplanted. This will lessen damage from the move substantially. Install a temporary filter such as a nylon stocking or something similar at the end of channels to catch debris.

Set small pots in gulleys so that they remain stable while roots are establishing. Keeping clones and seedlings firmly in channels with no vertical movement will reduce transplant shock and speed root growth. Movement of plants can cause damage to roots, which causes stress and possible root disease. Often the first signs include leaf tip burn and slow growth. Even minimal transplant shock will slow growth for several days.

Problems

Most hydroponic garden problems are solved by keeping the garden and surrounding area clean, and by controlling the nutrient solution’s dissolved oxygen levels, EC, and pH, and temperature in the reservoir and gulleys. See sections on each for specific information.

Broken or discolored roots found in reservoirs and filters indicate problems from disease, pests, oxygenation, heat, nutrients, and so on. More broken and discolored roots signify a bigger problem. Check for slow nutrient flow and stagnation. Both conditions can cause waterlogged roots. Make sure that gulleys and the entire system are as light-tight as possible to discourage algae growth.

An excellent troubleshooting guide can be found at www.amhydro.com.

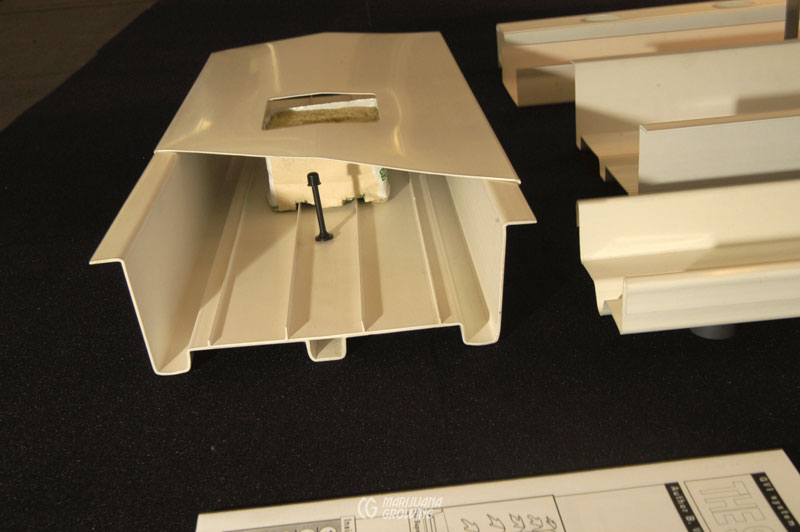

The ridges in each gulley bottom direct water and help add rigidity and stability.

There are many different styles of gulleys for NFT gardens.

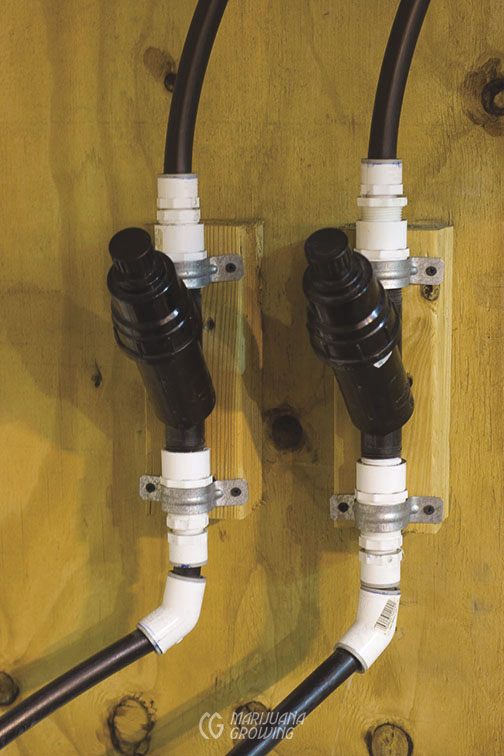

Good filters that are easy to access and clean are essential for NFT gardens.

Roots quickly grow into the main growing medium.

Hydro-Organic

Hydro-organic (aka organoponic) is growing in an inert medium fertigated with a soluble organic nutrient solution. When somebody talks about hydro-organics, they probably mean organic container culture. Organic fertilizers are most often defined as containing substances with a carbon molecule or a natural unaltered substance such as ground-up minerals. Many of the nutrients must be “processed” by microorganisms and be chelated before they are available to plants. These gardens can be top-feed, flood-and-drain, or wick. Refer to those specific sections in this chapter for more information.

Organic nutrients require places to collect. The concept is similar to buffering a video online. Without a place to accumulate, the rate of mineralization will not keep up with need. Much of the released nutrients would be used up by the microlife in the soil, or “volatized.” Other major issues arise with macro‑nutrients—most notably, P and Ca. It is impossible to grow 100 percent organic cannabis in hydroponics. There must be sources and pools where nutrients accumulate at appropriate levels. Oxygen is also required to break down organic complexes as well as the appropriate varieties and numbers of microflora to be effective.

Dedicated gardeners spend the time and trouble it takes to grow organically because the natural nutrients bring out a sweet organic taste in flower buds. Indoor and outdoor crops grown in les than 90 days do not have time to wait for organic nutrients to be broken down. Organic nutrients must be soluble and readily available for short-term cannabis crops to benefit.

An exact balance of organic nutrients can be achieved with experimentation and attention to details. Even when you buy ready-mixed commercial fertilizers like BioCanna or Earth Juice, you will need to try different feeding amounts and schedules to get the exact combination to grow a top-quality harvest. Always check with manufacturers for recommendations.

Taking an accurate EC reading or mixing the exact amount of a specific nutrient is very difficult in organic hydroponics. Chemical fertilizers are easy to measure out and apply, and it is easy to give plants the specific amount of fertilizer in each stage of growth.

Organic nutrients have a complex structure, and measuring content is difficult. Organics are difficult to keep stable, too. Some manufacturers with products such as BioCanna have managed to stabilize their fertilizers. When buying organic nutrients, always buy from the same supplier, and find out as much as possible about the source from which the fertilizers were derived. Always use fertilizers well before the expiration date.

Combine premixed soluble organic fertilizers with other organic ingredients to make your own blend. Experiment to find the perfect mix for the cannabis varieties being grown. Adding too much fertilizer can make the substrate toxic, binding nutrients to the point that they become unavailable. Foliage and roots burn when buildup is severe.

Soluble organic fertilizers are more difficult to overapply, yet they are also difficult to leach from the growing medium. And when overapplied, soluble organic fertilizers are more likely to cause symptoms that are hard to read. For example, too much bone meal causes a pH imbalance of the growing medium that manifests as leaf burn. Fertilizer recirculating systems are the trickiest to control. When the microbial life is off balance by a small amount and the conversion of released ammonium to nitrate is slowed, it causes a buildup to toxic levels.

Chelates and Nutrients

Mix seaweed with macronutrients and secondary nutrients to make a hydro-organic fertilizer. The amount of primary and secondary nutrients is not as important as the mélange of trace elements that are in an available form in the seaweed. Major nutrients can be applied via soluble fish emulsion for nitrogen, while phosphorous and potassium can be supplied by bat guano, bone meal, and manures. More and more organic gardeners are adding growth stimulators such as humic acid, Trichoderma, bacteria, and various hormones.

Minerals such as silica, nickel, cobalt, and selenium are not essential for plant growth but have the ability to enhance growth and development. They are needed in minute quantities and are provided via the contaminants in the water supply and fertilizer. Add humic and fulvic acids (available in mineral soils) to the hydroponic garden and soilless container gardens. Fulvic acid, a humic acid, is yellow in color and soluble. Humic acids are most effective as additives to the soil to help build soil and stimulate plant growth.

Humic acids have an important ability as chelating agents—they are, in fact, excellent in this role as they are strong enough to protect micronutrients but weak enough to release the micro‑elements to plants when required. Fulvic acid is particularly good for this role of natural chelation, because it has the ability to enter the plant and move throughout its tissue. In organic production gardens where synthetic chelation agents such as EDTA cannot be used, addition of humic acid appears to be the ideal way of ensuring that micronutrients remain available to the plant through a more natural form of chelation.

Organic nutrients are typically processed by microorganisms before plants can take them up. Humic acids promote the conversion of many elements into a form available to plants. Adding humic acids promotes microbial growth, helps decompose minerals and organic matter, and makes different elements available to plants. Iron would usually be supplied in a chelated compound. In an organic garden, fulvic acid is used instead. Humic and fulvic acids accelerate cell division and increase the rate of development and the length of root systems.

Hydro-organic gardens combine principles of hydroponics and organic gardening.

A dirty reservoir causes nonstop problems!

Hydro-organic nutrient mixes are heavier, requiring a stronger pump and heavy-duty filters.

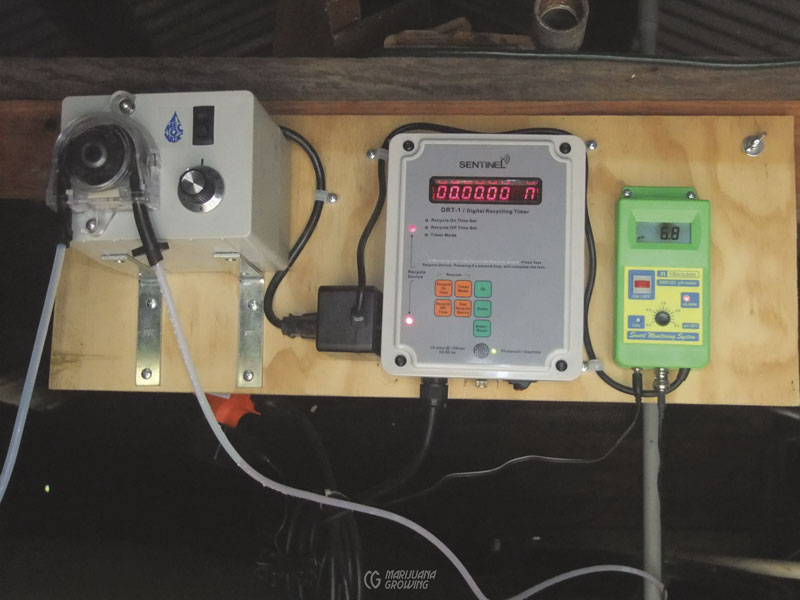

A constant-readout monitor/controller for nutrient solution takes the guesswork out of nutrient formula delivery.

Ebb-and-Flow Gardens

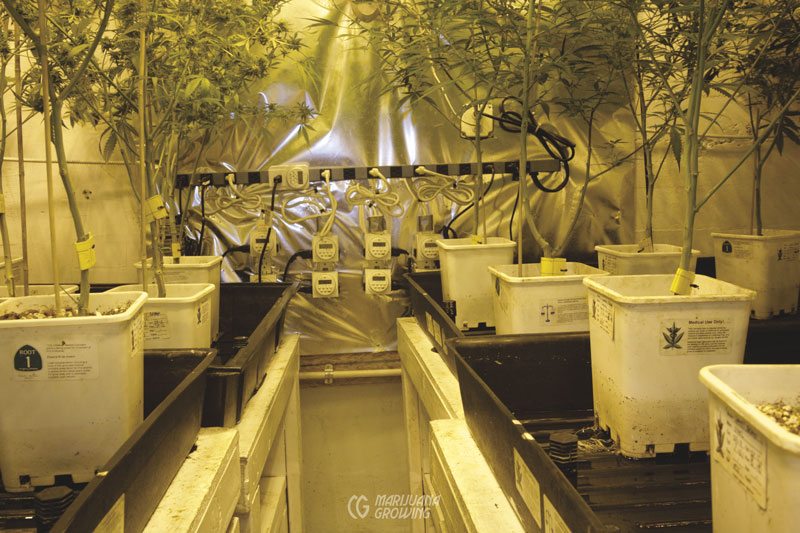

Ebb-and-flow (aka flood-and-drain) gardens are low-maintenance, simple, and inherently efficient by design. This is often the easiest and most cost effective hydroponic or container culture garden for indoor and greenhouse cannabis cultivation, whether growing just a few plants in a small area or a large garden.

Individual plants in pots or rockwool cubes are set on a special table with drainage channels and sides, a growing bed that can hold up to 4 inches (10.2 cm) of solution. The nutrient solution is pumped into the table or growing bed. The rockwool blocks or containers are flooded up through an inlet from the bottom, which pushes the old, oxygen-poor air out. Once the nutrient solution reaches a set level, an overflow pipe drains the excess back to the reservoir. At the end of the irrigation cycle, the pump is turned off and the solution drains and draws new, oxygen-rich air into the growing medium. The aerated substrate is just what roots need to take in nutrients at a rapid rate. A maze of drainage channels in the bottom of the table directs runoff solution back to the catchment tank or reservoir. This cycle is repeated several times a day. Ebb-and-flow gardens are ideal for growing clones, seedlings, and short plants in a sea of green (SOG) garden.

This ebb-and-flow garden has an air stone to increase nutrient-solution aeration.

Ebb-and-Flow Tables

Nutrient solution is pumped up into the bed via an inlet fixture and evacuated out the same inlet/drain. There is only one entrance and exit to clog, leak, or otherwise malfunction. Delivering nutrient solution via more than one outlet compounds problems every time a new emitter is added. An overflow fitting guarantees the nutrient solution will reach a specific level and not spill over the top of the table. Excess solution drains back into the reservoir via the overflow fitting. The solution is aerated when it cascades from the drain hole in the table into the reservoir below.

Ebb-and-flow tables or growing beds are designed to hold up to 4 inches (10.2 cm) of solution and let excess water flow freely away from the growing medium and roots. Nutrient solution is pumped up into the bed, filling it in 5 to 10 minutes. It should take about 8 minutes for a 350 GPH pump to fill a 4 × 8-foot (1.2 × 2.4 m) table with 40 gallons (151.4 L) of solution 2 inches (5.1 cm) deep. The solution is moved relatively slowly, and a low-volume 350 GPH (1325 LPH) pump is adequate (see “Nutrient-Solution Pumps”) These gardens are fairly quiet and use less power than some other setups.

The bed should drain faster than it takes to fill. Total fill-and-drain time cannot exceed 20 minutes or roots will be deprived of oxygen too long and will drown, rot, and attract problems. Passive drainage requires a large tube (at least 2 inches [5.1 cm]) to allow solution to drain rapidly. Complete and speedy drainage is essential so that the growing medium pulls fresh air into the growing medium and root zone. Excess solution sitting in substrates after irrigation does not allow adequate oxygen to enter. Slow suffocation occurs when nutrient solution does not drain completely. The surface of the growing media must also dry out completely to help prevent algae growth and fungus gnat infestations. Avoid algae growth on substrate surface by covering to exclude light. Remove any debris—dead leaves, organic matter, and so forth—from the surface of the growing medium to deter pests and diseases. Keep clean, pest-and-disease-free medium enclosed in plastic until it is used.

The table must be sturdy enough to hold a volume of water. For example, a 4 × 8-foot (1.2 × 2.4 m) table that is 2 inches (5.1 cm) full holds 40 gallons (151.4 L) of solution that weighs 240 pounds (108.9 kg).

When flooded with 1 to 2 inches (2.5– 5.1 cm) or more of nutrient solution, the growing medium wicks up the solution into the freshly aerated medium. Tables with drain channels require deeper flooding, up to 4 inches (10.1 cm), to compensate for channels. Homemade tables with no drain channels require shallower levels. But such tables could also allow pools of stagnant water if not perfectly flat and with an adequate incline.

Adjustable-height legs, similar to those found on a washing machine, work well to support ebb-and-flow garden beds. Individual legs can be adjusted to dial in the slope of a garden bed table. Allow enough incline so that solution drains readily but not so much slope that plants at the high end do not receive enough solution. An 8-foot-long table should have a slope of about 0.5 to 0.75 inch (about 1.3–1.9 cm). Growing beds longer than 10 feet (3 m) drain slowly, and solution stays on the beds longer than roots are able to use it.

Roots grow out drainage holes but stop growing when they come in contact with air between irrigation cycles.

Each bed in this flood-and-drain garden is controlled by timers that can be seen at the end of the aisle.

These plants grew for about a week too long and needed to be pruned from below. But as you can see, the buds on the top of the plant are at least 2 feet (61 cm) long.

Growing Mediums

Growing medium must wick solution up and must also hold plenty of air. For example, a 4-inch (10.2 cm) rockwool cube flooded with 1 inch (2.5 cm) of solution wicks up about 3 inches (7.6 cm) into the cube. Growing mediums must provide adequate capillary action for water uptake and movement. Rockwool, soilless mix, and coco are the preferred growing mediums for ebb-and-flow gardens. However, some people do use expanded clay pellets and irrigate deeper and more often.

Flood-and-drain tables are scrubbed down by hand and disinfected between crops.

Plants wick up nutrient solution in the ebb-and-flow tables.

Drains should be efficient and simple to clean.

Adjustable legs make it easy to level and add an incline to a growing table.

Irrigation

Flood the table with 1 to 2 inches (2.5–5.1 cm) of solution to ensure even nutrient-solution distribution. Avoid lightweight mediums such as perlite that may cause containers to float and fall over. A large volume of water is necessary to fill the entire table. Make sure the reservoir has enough solution to flood the reservoir and still retain an absolute minimum of 50 percent extra to allow for daily evaporation. Before introducing plants, calculate the amount of solution needed to flood the table. Also calculate the size of reservoir needed. Use the tables at right as a guideline.

| TABLE | GALLONS FOR | RESERVOIR | GALLONS FOR | RESERVOIR |

| Size (ft) | 1-inch Depth | Size (gal) | 2-inch Depth | Size (gal) |

| 1 × 2 | 1.25 | 2.5 | 2.5 | 5 |

| 2 × 2 | 2.5 | 5 | 5 | 10 |

| 2 × 3 | 3.75 | 7.5 | 7.5 | 15 |

| 2 × 4 | 5 | 10 | 10 | 20 |

| 3 × 3 | 5.62 | 11.24 | 11.24 | 22.48 |

| 3 × 4 | 7.5 | 15 | 15 | 30 |

| 3 × 5 | 9.4 | 18.8 | 18.8 | 37.6 |

| 3 × 6 | 11.3 | 22.6 | 22.6 | 45.2 |

| 4 × 4 | 10 | 20 | 20 | 40 |

| 4 × 5 | 12.5 | 25 | 25 | 50 |

| 4 × 6 | 15.6 | 31.2 | 31.2 | 62.4 |

| 4 × 7 | 17.5 | 35 | 35 | 70 |

| 4 × 8 | 20 | 40 | 40 | 80 |

| 4 × 9 | 22.5 | 45 | 45 | 90 |

| 4 × 10 | 25 | 50 | 50 | 100 |

| TABLE | CUBIC LITERS FOR | RESERVOIR | CUBIC LITERS FOR | RESERVOIR |

| Size (cm) | 3-cm Depth | Size (L) | 6-cm Depth | Size (L) |

| 30 × 60 | 5400 | 5.4 | 10.8 | 21.6 |

| 60 × 60 | 10800 | 10.8 | 21.6 | 43.2 |

| 60 × 90 | 16200 | 16.2 | 32.4 | 64.8 |

| 60 × 120 | 21600 | 21.6 | 43.2 | 86.4 |

| 90 × 90 | 24300 | 24.3 | 48.6 | 97.2 |

| 90 × 120 | 32400 | 32.4 | 64.8 | 129.6 |

| 90 × 150 | 40500 | 40.5 | 81 | 162 |

| 90 × 180 | 48600 | 48.6 | 97.2 | 194.4 |

| 120 × 120 | 43200 | 43.2 | 86.4 | 172.8 |

| 120 × 150 | 54000 | 54 | 108 | 216 |

| 120 × 180 | 64800 | 64.8 | 129.6 | 259.2 |

| 120 × 210 | 75600 | 75.6 | 151.2 | 302.4 |

| 120 × 240 | 86400 | 86.4 | 172.8 | 345.6 |

| 120 × 270 | 97200 | 97.2 | 194.4 | 388.8 |

| 120 × 300 | 108000 | 108 | 216 | 432 |

To check the moisture level, saturate substrate with nutrient solution. Weigh rockwool containers or blocks when saturated, and weigh them again a few hours to a day later to check the amount or percentage of water used. For example, a block that weighs 4 ounces (11.8 cl) when saturated will weigh 2 ounces (5.9 cl) when 50 percent of the nutrient solution has been used. Check with the grow medium or substrate manufacturer for recommendations on moisture content and irrigation frequency.

To learn the amount of solution a grow medium contains, weigh it when saturated and after squeezing lightly. Water rockwool when it is 50 percent dry. Remember, rockwool holds a lot of moisture and air, even when saturated. Irrigation frequency and volume change substantially when temperatures go down and light is lacking. Overwatering is much more likely when temperatures cool. Do not let nutrient solution stand on the table for more than 20 minutes. Submerged roots drown in the depleted oxygen environment.

Flooding garden beds is the easiest and most efficient form of irrigation.

Steel tables with wooden supports bear all the weight of the growing table. The tables are equipped with wheels so an aisle can be opened between them.

Ebb-and-Flow Irrigation Guidelines

1. Rockwool cubes: 3 times @ 10 minutes

2. Soilless mix: 3 times @ 10 minutes

3. Expanded clay: 6 times @ 10 minutes

4. Lava rock: 12 times @ 10 minutes

Note: Lower the EC to between 600 and 800 ppm when increasing feeding frequency. It is easy to burn plants when irrigation frequency increases.

The first cycle should start first thing in the morning and be followed by cycles 2 to 4 hours apart. The irrigation schedule will fluctuate depending upon variables such as temperature, humidity, plant age, and growth rate. No watering is necessary at night. The entire irrigation cycle must be completed in no more than 20 minutes total, or roots will drown. The fill time is important and should occur relatively quickly, preferably in ten minutes or less. Drain time should be relatively quick so that the draining solution sucks new, oxygen-rich air into the container or cube. This is an essential principle of irrigation in any flood-and-drain garden.

A large amount of nutrient solution is required to fill garden beds. For example a 4 × 8-foot (1.2 × 2.4 m) table requires 40 gallons (151.4 L) of solution to reach a depth of 2 inches (5.1 cm). Consequently a large reservoir is necessary. Garden beds are flooded in sequence or will have individual reservoirs when more than one such table is set up in a growing area.

The entire table floods and is exposed to air, causing a huge volume of water from the solution to evaporate into the air. This creates more humid atmospheric conditions. Extra ventilation will be necessary to whisk away moist air. The balance of the nutrient solution is also affected and must be compensated.

Since all plants are in the same bed and are irrigated together, pests and diseases can also run through an entire garden quickly. Keeping garden rooms clean is essential to avoid the spread of pests and diseases.

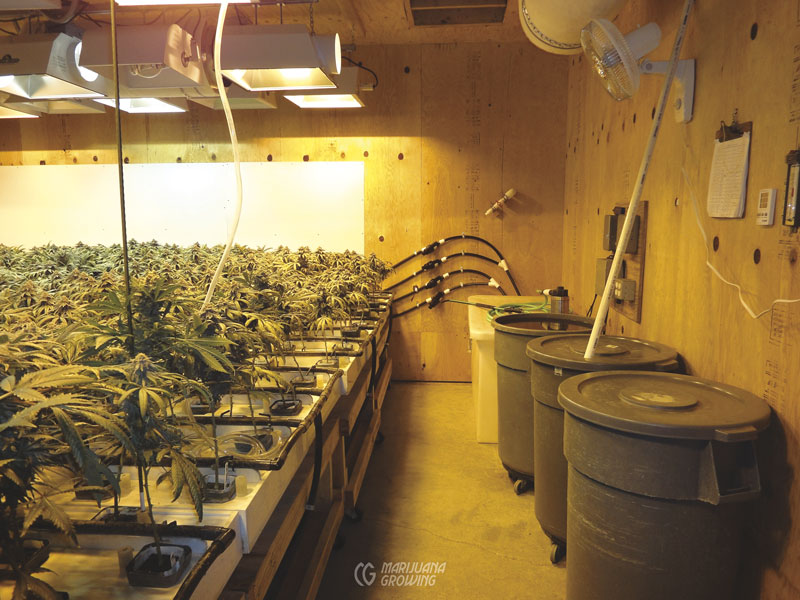

This rockwool hydroponic garden by Trichome Technologies is completely automated.

Each clone in this top-feed garden is fed via a spaghetti tube attached to an emitter.

Roots hang in the moist air below the garden bed. Irrigation water is recirculated back to the reservoir.

Variations of Ebb-and-Flow

A few gardeners place a capillary mat between the table and containers to hold nutrient solution and promote root growth. I do not recommend this practice. Once plant roots have anchored into the capillary matting, they cannot be moved without damaging roots. Excessive algae growth and waterlogged roots that leads to root rot are inherent problems with this practice. After irrigation, the water under matting takes a very long time to dry.

Top-Feed Gardens

Top-feed hydroponics and container culture gardens are efficient and productive, and once set up, they are easy to control and maintain. The nutrient solution is metered out in specific doses at intervals over time and delivered to individual plants via spaghetti tubing or an emitter placed near the base of the stem. Aerated nutrient solution flows down into the growing medium. Roots take in some of the nutrient solution and the balance drains out the bottom. The runoff solution is directed back to the reservoir as soon as it drains from the growing medium. Rockwool and expanded clay pellets are the most common growing mediums in hydroponics, and container culture gardens commonly use such mediums as soilless mix, coco coir, and soil. Versatile top-feed gardens can be used with individual containers slabs in individual beds or lined up on tables.

Top-feed 5-gallon (18.9 L) containers of growing medium work well to grow large plants that may require support. Small 1- to 3-gallon (3.8–11.4 L) containers work well for smaller plants.

Top-Feed Containers

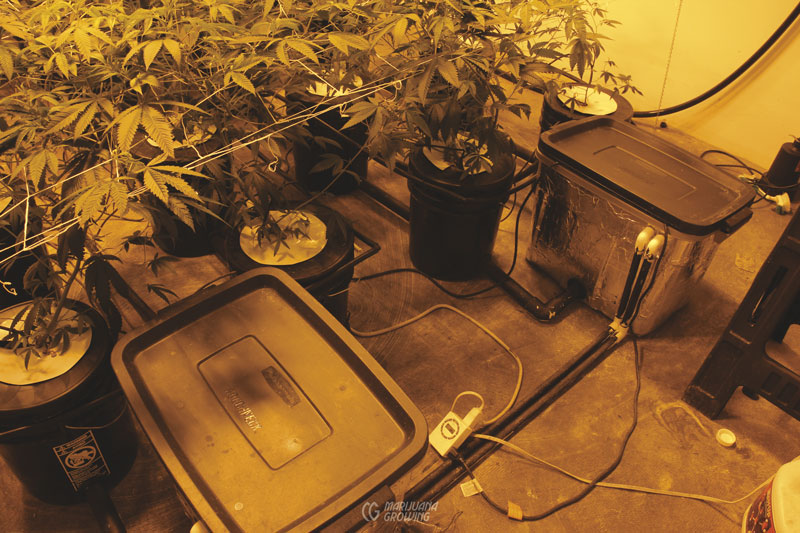

Individual self-contained recirculating top-feed container gardens consist of a net pot or pots nested in the lid of a container/reservoir containing a pump. Popular setups include a single net pot suspended in the lid of a 5-gallon container/reservoir or multiple net pots suspended in the lid of a larger container. A submersible pump in the bottom of the container lifts nutrient solution to irrigate individual plants via spaghetti tubing and emitters around the stems. Expanded clay pellets are the preferred growing medium for continuous irrigation, and rockwool for intermittent application. Nutrient solution drips down through the growing medium and runs to waste or falls back into the reservoir before recirculating. The solution is aerated every time drops fall and splash down into the self-contained reservoir below. The pump must cycle nutrient solution 24 hours a day to ensure that water is aerated. This garden does not need a timer.

Roots grow down into the nutrient solution and, over time, form a mass on the bottom. Irrigation from the top circulates aerated nutrient solution and flushes out old, oxygen-poor solution. Some containers have a 1-inch (2.5 cm) pipe to draw air directly down into the root zone. Nutrient-solution aeration in the bottom of the container can become a constant problem. Place a grate or platform in the bottom of the container so roots do not sit in water and drown. If the nutrient solution is more than an inch (2.5 cm) deep, an air stone attached to an external air pump must be added to the bottom of the reservoir to ensure that roots receive enough oxygen. At this point the garden changes names. (See “Deep Water Culture” in this chapter.)

Individual top-feed 5-gallon (18.9 L) containers are easy to move and perfect for growing 1 or 2 large plants, including mothers. Culling out and replacing a slow-growing or diseased plant is also quick and easy. Controlling each container’s nutrient solution pH, EC, and temperature are the tradeoffs for versatility.

Top-feed gardens cycle for 5 minutes or longer and should be irrigated at least 3 times daily. Often gardeners cycle the nutrient solution 24 hours a day, especially when growing in fast-draining expanded clay or similar mediums. In fast-draining mediums, overhead irrigation is continual. Microirrigation in coco coir is generally 4 to 5 times daily.

This top-feed container is irrigated by a spaghetti tube that circles the plant. Nutrient solution is delivered around the circle so it penetrates growing medium evenly.

Multiple-container, recirculating, top-feed gardens employ several containers that are connected to a main reservoir. A flexible drain hose is attached near the bottom of the container/reservoir. The hose is connected to a drainage manifold that shuttles runoff nutrient solution between reservoirs. A central pump distributes solution from a central reservoir to individual containers via an irrigation manifold and spaghetti tubing. Once delivered, the nutrient solution flows and percolates through the growing medium. Roots take in the aerated nutrient solution before it drains onto the tray and back to the central reservoir.

Each reservoir below the growing container can hold an inch (2.5 cm) or more of water. It is important to regularly cycle irrigation in these gardens, so the solution in the bottom of the container does not stagnate and drown roots— remember the 20 minute rule! Top-feed containers can also be lined up on a drainage table. Square containers make most efficient use of space.

More extensive plumbing allows nutrient pH, EC, and temperature to be controlled via the central reservoir. The reservoir must be located below growing containers to avoid high levels of solution stagnating in the bottom of containers. A reservoir located at the same level or plane as growing containers causes the levels of all reservoirs— central and all container/reservoirs— to seek the same solution level.

Individual containers in top-feed gardens can be easily arranged to fit into the allotted garden space. Plants can also be transplanted or removed from pots and cared for individually.

This top-feed container has a reservoir and a pump.

Multiple containers are connected to the same drainage tubing. The containers are irrigated from the top and all drain back into the same reservoir.

Top-Feed Slabs

Top-feed rockwool and coco coir slabs (bats) that are covered with plastic serve as growing containers. Clones and seedlings are grown in individual containers, most often rockwool blocks, and set on top of slabs (transplanted). See “Transplanting Rockwool Cubes onto Slabs,” at right.

An irrigation tube is attached to a short manifold with spaghetti tubes fed by a pump submerged in a reservoir in a recirculating garden. Spaghetti tubes with or without emitters are attached to thin stakes that are anchored in the growing medium. They deliver a measured dose of nutrient solution. The nutrient solution is aerated as it is applied, before being absorbed by the growing medium and draining back to the reservoir.

In recirculating gardens, slabs should be set on tables that have drainage channels to carry runoff nutrient solution back to the reservoir. Elevated tables are not necessary in run-to-waste gardens. Tables with a flat surface do not allow adequate drainage, and solution tends to puddle and stagnate, quickly leading to problems with root rot, pests, and diseases. Excess nutrient solution drains from pots onto the table with drainage channels and is carried back to the reservoir. Make sure the table is set up on an incline so it drains evenly. Pockets of standing water on the table contain less oxygen and promote rot.

At transplanting, the bottoms are cut out of containers full of coco. Roots grow down into the coco slabs. Individual plants are watered with spaghetti tubing from above.

Many plants can fit in a small area when growing in coco slabs.

Individual trays with drainage channels can also hold slabs. The trays are connected by a manifold of tubes or troughs that drain runoff to waste or back to the catchment tank. Versatile individual trays are easy to configure for different-sized gardens, but algae growth is common when directing runoff back to the reservoir via an open-faced trough.

Transplanting Rockwool Cubes onto Slabs

Root clones and grow seedlings in 1- to 2-inch (2.5–5.1 cm) rockwool cubes. When roots are established and just starting to grow through the sides, transplant into larger 3- to 4-inch (7.6–10.2 cm) rockwool blocks. Avoid root damage and minimize shock by not letting roots grow more than a quarter inch (0.6 cm) beyond the sides of cubes before transplanting into blocks.

Transplant blocks onto slabs when the first roots start to show out the bottom of blocks. A 40-inch (101.6 cm) slab can easily support three individual plants. Transplant each of three individual blocks onto a slab by cutting an “X” that corresponds to the corners of the block on top of the slab. Peel the plastic covering back and set block on top of conditioned slab. Hold block in place with toothpicks or thin stakes until established.

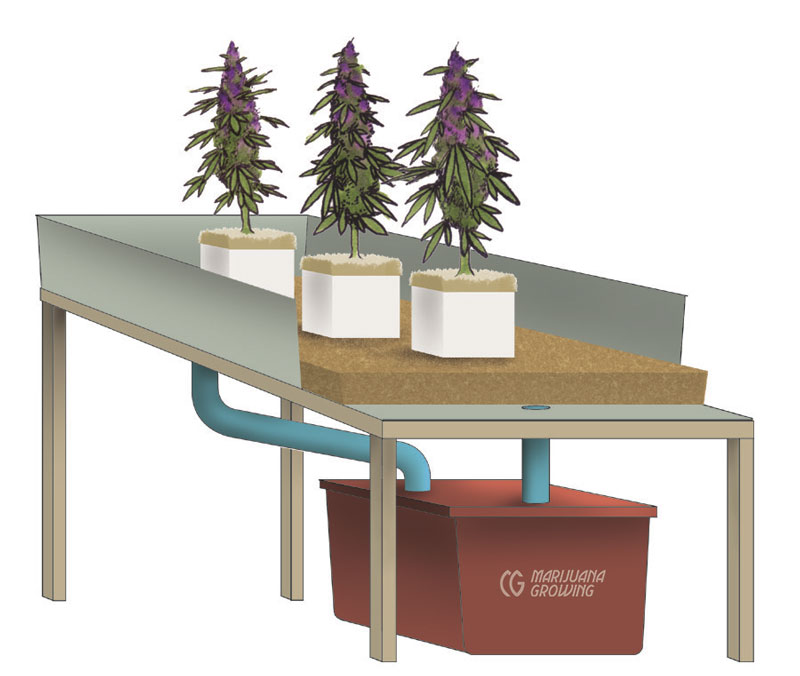

This cutaway drawing shows that nutrient delivery is simple and easy with a top-feed slab garden. Aerated nutrient solution is metered via emitters onto a growing cube. Aerated solution percolates down through the medium. Channels in the bottom of the tray speed drainage back to the reservoir.

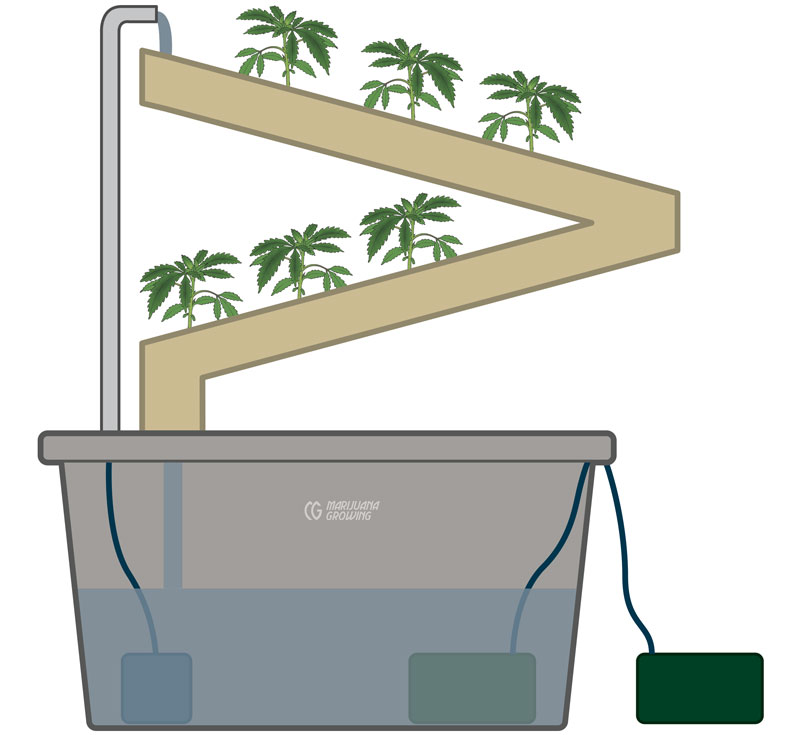

DFT gardens are ideal for growing along a well-illuminated wall.

Vertical Top-Feed Gardens

Growing small plants in a vertical garden saves space and increases yield per square foot. Fences, sunny garden walls, and bare but well-illuminated walls around garden rooms are usable garden space. Side light in garden rooms is often underutilized or wasted. Backyard fences and walls—sunny, partially shady, and even shady—are also excellent locations for vertical gardens.

DFT gardens and top-feed irrigation can be mounted on a fence or garden wall. Containers can be placed in a trough along the walls of indoor garden rooms to take advantage of lost side light. An automated top-feed spaghetti-tubing manifold can deliver nutrient-solution. Or a sunny backyard fence or wall can be fitted with 4-inch (10.2 cm) tubing to make a DFT garden. Extra heat is absorbed and emitted from fences and walls. Take care to shade nutrient tubes to keep solution cool and prevent roots from baking. Fences and garden walls heat up to beyond 100°F (37.8°C) in direct sunlight. (The fence in my backyard reaches temperatures of about 130ºF (54.4ºC) during the summer.) In such hot conditions, it would be almost impossible to succeed with this type of garden. Protect gardens and plants by spacing tubes and containers away from excessive heat, and shade all garden beds and tubes. Cool nutrient solution by setting reservoir on cool ground in a shady location. Artificially cooling nutrient solution is expensive, impractical, and environmentally unsound.

A vertical garden that consists of shelves stocked with a layer of cannabis plants in 1- to 3-gallon (3.8–11.4 L) containers is another growing option. Plants are stacked on shelves and trained to grow out and up toward lights located in the center of the room. Shelving can be placed all the way around the lamps. Containers are irrigated with spaghetti-tubing connected to individual emitters. A trough or plumbing tubes below containers carry nutrient solution back to the reservoir.

The light can be either fixed in the center of the room with shelves surrounding it, or mobile and able to move out of the way for maintenance. The latter arrangement is a lot of work to set up and maintain. Few gardeners have the time and energy to make it work properly. Several commercial, vertical, space-saving gardens are still on the market; others have been short lived. Search “vertical marijuana garden” online for more information.

An A-frame structure having growing containers on walls of both sides and a reservoir below will save space. Orient the sides of the frame so that they receive the most light possible.

Vertical gardens take advantage of all available HID light.

Run-to-Waste (RTW) Gardens

Run-to-waste hydroponics and container gardens are among the least expensive, simplest to construct, and easiest to maintain. Many commercial flower and vegetable growers use RTW gardens. Once the nutrient solution is applied, it is absorbed by the growing medium and roots; the excess drains to waste. Used nutrient solution is not recirculated and recycled. Gardeners fertilize perennial plants, lawns, and flower or vegetable gardens with the runoff nutrient solution.

A basic, manual, run-to-waste garden is simple and efficient.

A run-to-waste garden uses about the same amount of fertilizer as a recirculating garden uses. The nutrient solution is more dilute in a RTW garden. In most recirculating gardens, the nutrient solution is dumped out and changed every 5 to 7 days or the plants’ waste products will overwhelm the chemistry of the solution. The solution is concentrated and imbalanced when thrown out. A run-to-waste garden expels a small amount of nutrient solution with every irrigation cycle. Regardless of origin, the “used” nutrient can be recycled to fertilize the outdoor garden. Please do not send the used solution down household drains! Dump it in different places outdoors in order to avoid a buildup of fertilizer salts.

A nutrient solution is applied in a run-to-waste garden, and there is reduced chance of problems with pH fluctuations, nutrient buildups, and imbalances. A consistent formula with the proper pH is applied regularly. The formula is dilute so the extra water in the solution will wash away excess salts. Fertilizer residues do not have a chance to build to toxic levels.

Ideal growing mediums for RTW gardens retain moisture and air well. Substrates that retain moisture and air for a long time require less-frequent watering. Often watering once a day or every few days is all that is necessary. In such gardens, simple manual irrigation is possible. A runoff of at least 20 percent is necessary to ensure a healthy root zone.

There are several inherent benefits to a RTW garden that lend themselves to hot climates and avoiding the spread of diseases. Roots are easier to keep cool on hot days because the nutrient solution is applied only once and not given a chance to recirculate and heat up. The nutrient solution can also be kept in a cool location. Keeping the root zone cool during very hot days can make an incredible difference in plant growth.

Plants can be easily isolated with a run-to-waste garden. Since the nutrient solution is applied only once and not recaptured, it can be applied to individual plants and not be recirculated and applied to all plants. In a recirculating garden, if one plant has a disease, all plants will be affected by the same disease.

Manual Run-to-Waste Gardens

Manual RTW gardens with containers full of substrate will hold moisture longer and requires less-frequent irrigation. Favorite mediums for low-tech manual RTW gardens include a mix of perlite/ vermiculite, horticultural-grade coco coir, and soilless mix such as Pro-Mix. Avoid low-quality coir as it tends to harbor sodium and requires heavy presoaking, washing, and pH correction.

Five-gallon (18.9 L) containers are excellent for a low-maintenance garden. To make containers into growing containers, drill a hole as close to the bottom of the container as possible so that very little water sits on the bottom. Insert a thru-hull fitting and attach a drainage hose to the fitting or simply let the irrigation solution run out the fitting or hole into another container. Run the hose down into another container to catch the runoff that will be used in the outdoor garden. Put a screen in front of the drainage hole to keep it free of blockage.

This gardener waters plants by hand so that 20 percent runs out the bottom of each container. Individual containers drain into a larger container that is lifted out and dumped in the outdoor garden.

These expanded clay pellets are of different sizes and are irregular in shape. This fine grade of expanded clay pellets holds more nutrient solution for longer periods of time. It also holds plenty of air.

Automated Run-to-Waste Gardens

Automated RTW gardens use a pump and timer to apply nutrient solutions more frequently at regular intervals. The gardens can be set up using the “Top-Feed Gardens” or “Ebb-and-Flow Gardens” above as a guideline. Mediums that work well with more frequent irrigations include expanded clay, coco coir, and rockwool. Algae grow on any uncovered medium with a moist surface, attracting fungus gnats, stem rot, and other problems. Rockwool, coco coir, and peat tend to stay too wet in the upper parts and too wet toward the bottom when using large volumes in tall containers. But when in a low profile, slabs and cubes are much easier to keep moisture and air retention near ideal levels. Regardless of how often plants are watered, there must be at least 20 percent runoff every time.

This simple run-to-waste system holds runoff water in the soil below.

This amazing run-to-waste garden is filled with small expanded clay pellets to a depth of 3 inches (7.6 cm).

These plants receive plenty of light and are irrigated with nutrient solution several times a day. As you can see, they are strong and healthy.

Wick Gardens

Low-tech wick gardens have no moving parts to break or malfunction. Low initial cost and little maintenance are other positive points. These gardens consist of a container full of an absorbent growing medium such as coco coir, rockwool, or soilless mix containing more absorbent and air-holding mediums such as peat. A wick made from cotton rope, yarn, or other absorbent material transfers nutrient solution from a reservoir to the growing medium via capillary action.

Simple low-tech wick gardens may not be well suited to the demands of fast-growing cannabis plants. If the growing medium stays too wet and soggy, it can fail to supply enough oxygen for rapid nutrient uptake.

The wick in this passive garden continually draws nutrient solution up to roots.

Flood Wick Gardens

High-tech flood wick gardens rely on nutrient solution delivered manually or via a pump. These advanced wick gardens are actually half of a flood-and-drain garden. The difference is that they do not drain; nutrient solution is flooded into a growing table or area with sides to contain the liquid. The liquid is slowly absorbed by plants in containers for one to several days afterward.

Setting up a flood garden is relatively easy and inexpensive. The growing bed can be set up on a table or directly on the floor. The bed must be flat and level so that nutrient formula is available to be wicked up by all plants at the same rate. Unleveled growing beds cause plants on the low end of the table to receive more solution than those on the high end.

These flood wick gardens work best with 1- to 3-gallon (3.8–11.4 L) containers somewhat wider than they are deep. Larger containers tend to hold too much solution, which promotes soggy substrate, low oxygen levels, and root disease. Containers with holes around the bottom rim work better than pots with holes in the bottom only. Containers can be set on capillary mats.

This flood garden is so crowded with plants that watering any other way is impossible.

An absorbent substrate such as rockwool or coco coir that holds plenty of air and solution is preferable for these gardens. Substrates can also be mixed together to achieve the desired ratio of air to nutrient solution. There are many variables in substrates, and giving ratios is difficult.

Irrigation cycles depend upon plant size, growth habit, humidity, and temperature of the growing area and substrate, as well as the depth of the irrigation solution. When plants are small and growing slowly they consume less water and nutrients and need less-frequent irrigation. In general, irrigate with enough solution to cover the bottom of the table to a depth of 0.5-inch (1.3 cm) so that all the solution is wicked up in a few hours. Increase the frequency and depth of nutrient-solution irrigation as plants’ needs grow. Small plants should use the nutrient solution in 5 days or less. Medium to large plants commonly need irrigation every 2 to 5 days.

Mix nutrient solutions with a low EC and use very clean (low EC or reverse osmosis) water. Since the nutrient solution does not drain away from roots, mineral salts have a big opportunity to build up to toxic proportions. Prevent possible fertilizer salt buildup in the root zone by applying low EC solutions so that plants use nutrients before they build to toxic levels.

I have seen such gardens work quite well even though the substrate appears to stay too wet. Here is why: the higher the salinity, the moister the medium needs to be. Allowing the medium to dry out even a little bit causes ions to come out of solution and onto the medium. When water is reapplied, all the ions go back into solution, even the ones that normally are there, so nothing is on the particle and the EC for a short time spikes causing damage. With proper care, this type of garden can be successful.

If porosity is correct, the medium only appears to stay wet. The reality is that water stays in the small pores and weeps to the larger ones with air. The air pores never fill up; air does not really need suction to get into the root zone with correct pores. The results are a better-watered plant than most, with a steady supply of nutrients, and the roots do not drown. However, salts can accumulate in the medium’s topmost layer. The roots cannot fill the total column of medium because of this layer. The level of O2 is not as high as it would be with suction. The ratio of available ions is skewed to reflect the leftovers.

The feeding schedule should include low EC values to avoid salt accumulation, and a fertilizer would really need to be calibrated to do better than average. This is to allow for irrigation water, plant types, life stage, and seasons.

Under high-salinity conditions it becomes critical to (1) never allow a dry-down, and (2) allow for evaporation between irrigations, which forces us to water more and more often (or further decrease the feed EC) until the roots drown or we can put nothing else in the supply water. Periodic leaching of the medium is essential.

Canna A and Canna B are designed specifically for the coco that Canna sells. Designing nutrient for proprietary products has given this company a big edge for research and development.

General Hydroponics produces several different formulas that are very popular among medical cannabis gardeners.

Humboldt Honey from Humboldt Nutrients is a good example of an organic-based fertilizer company that gives medical cannabis gardeners in California the mixes they want.

A clean garden area is essential. Trichome Technologies’ gardeners keep all their containers organized and labeled.

Canna produces one of the many fertilizer formulas that are packaged in two parts.

Aquaponics

Aquaponics combines traditional aquaculture (raising aquatic animals) with hydroponics in a symbiotic sustainable environment. The toxic by-products in solution generated by aquatic animals are directed into a hydroponic garden. These toxins, many of which are nutrients, are filtered out and used by plants to grow. Once cleansed of toxins, the water is recirculated back to the fish, shellfish, mollusks, and so on.

Aquaponic gardens are not yet common among cannabis gardeners. The closest thing to an aquaponic garden I have seen was in the mid-1990s in Vancouver, Canada, where an eccentric grower was filtering wastes from his freshwater predatory fish tank into his container culture nutrient tank. Technically, this was only half of an aquaponic garden.

Aquaponic gardens are more complex than standalone hydroponic or container culture gardens and are beyond the scope of this book.

Hydroponic Nutrients

Nutrients are necessary for cannabis to grow. These nutrients must be broken down chemically within the plant, regardless of origin, organic or mineral.

The nutrients could be derived from natural organic bases, or they could be simple chemical elements and compounds, man-made or naturally occurring. When properly applied, each type of fertilizer, organic or chemical, theoretically produces the same results.

Soluble complete nutrients properly applied under the right conditions are immediately available for uptake. Fertilizer designed for use in soil is unsuitable for hydroponics or container gardens because it is not “complete” and does not contain all nutrients a plant needs to grow. Low-quality fertilizers contain impure components that often leave residue and sediments. These impurities build up in reservoirs, containers, and irrigation tubes and nozzles, causing extra maintenance and other problems.

Caution! These impurities will build up in the plant faster than in the soil.

Premium complete fertilizers designed for cannabis container culture and hydroponics are soluble and mixed in the proper ratios to form a balanced formula that includes all the necessary nutrients. Commercial premixed solutions are diluted or dissolved in water before use. These fertilizers come in 1, 2, 3, 4, or more parts. There is a “base” formula that separates calcium from other nutrients, all of which are soluble and dissolve in solution, but calcium will combine with many other elements when at the right level. When united in a concentrate, the two (calcium and any other nutrient) combine, precipitating and falling to the bottom of the reservoir, unavailable to plants.* It is easy to change the ratio of the mineral elements by mixing other components of the formula to tailor the mix to the native water limitations or the plant growth stage—seedling, vegetative, and flowering. Special nutrient formulations are available for people with “hard water” that contains large amounts of calcium. For more specific information, check the fertilizer application chart provided by manufacturers.

*Note: Be wary of fertilizers that separate out many nutrients into many parts. This is often done to simply increase the product line and make more income!

Purchase 1- and 2-part nutrients in powder or liquid form

Purchase 1, 2, 3+ formulations in liquid form

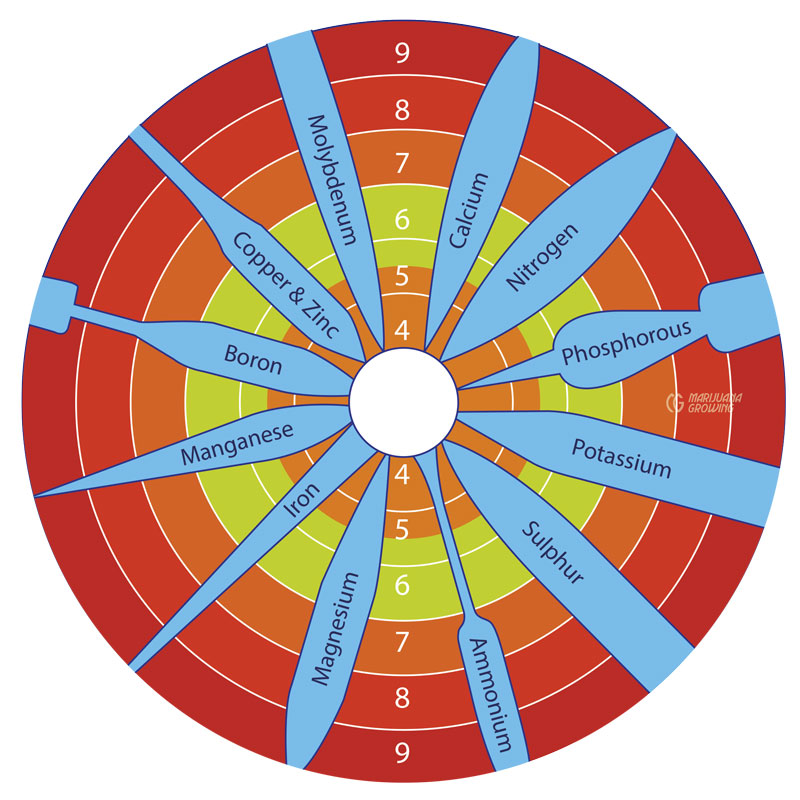

Soluble complete “hydroponic” fertilizers (nutrient formulas or recipes) are diverse combinations of chemical salts. Mix a predetermined amount of fertilizer concentrate with water to make a nutrient solution. The most frequently used macronutrient chemicals include potassium nitrate, calcium nitrate, potassium phosphate, and magnesium sulfate. Plant nutrients (inorganic and ionic form) are the dissolved cations (positively charged ions) Ca2+, Mg2+, and K+. The major nutrient anions (negatively charged ions) in nutrient solutions are NO3¯ (nitrate), SO42¯ (sulfate), and H2O4P¯ (dihydrogen phosphate). Micronutrients used in hydroponic formulas are Fe (iron), Mn (manganese), Cu (copper), Zn (zinc), B (boron), Cl (chlorine), and Ni (nickel). Chelating agents are regularly added so that Fe stays soluble. Plants use water and some nutrients faster than others; this changes the composition of the nutrient solution and alters the pH. Plants also give off ions such as hydrogen, which will drive the pH up and down, depending upon circumstances, as well making elements such as phosphates more soluble.

Nutrient-solution Composition

The table below is a guideline of acceptable nutrient limits for cannabis expressed in parts per million. To avert nutrient deficiencies and excesses, do not deviate too far from these ranges.

| EXPRESSED IN PPM | CHEMICAL | LIMITS | LIMITS | LIMITS | LIMITS |

| Element | Symbol | Low | Medium | High | Average |

| nitrogen | N | 150 | 650 | 1000 | 250 |

| potassium | P | 100 | 300 | 400 | 300 |

| phosphorus | K | 50 | 100 | 100 | 80 |

| calcium | Ca | 100 | 350 | 500 | 200 |

| magnesium | Mg | 50 | 100 | 100 | 75 |

| sulfur | S | 200 | 700 | 1000 | 400 |

| iron | Fe | 2 | 7 | 10 | 5 |

| manganese | Mn | 0.5 | 3 | 5 | 2 |

| copper | Cu | 0.1 | 0.35 | 0.5 | 0.05 |

| zinc | Zn | 0.5 | 1 | 1 | 0.5 |

| molybdenum | Mo molybdate | 0.01 | 0.035 | 0.05 | 0.02 |

| boron | B | 0.5 | 3 | 5 | 1 |

Main reasons nutrient deficiencies occur:

- Low nutrient strength—not enough nutrients for plant growth

- Imbalanced formula that lacks one or more elements

- Missing fertilizer element or wrong element in mix

- Balanced solution, but reactions with growing media prevent nutrient uptake

- Balanced solution, but conditions inside plant prevent nutrient uptake

Homemade Nutrients

Gardeners who mix their own nutrients from dry components save hundreds, often thousands, of dollars every year. Most small-scale cannabis gardeners opt to purchase expensive premade formulas from hydroponic stores. Preformulated nutrients are usually the best option for small-scale gardeners. The commercial formulas usually contains all necessary nutrients, and they are available to plants for uptake.

Look forward to at least an eightfold savings when mixing nutrients from scratch. For example, a gallon (3.8 L) of store-bought dilute nutrient (EC 2.0) costs about $0.25 USD a gallon (3.8 L). The same gallon (3.8 L) of nutrient mixed at home costs $0.03 USD a gallon (3.8 L) for two-part soluble powders.

Mix pH Up or pH Down in water for a 10 percent solution, and then use this dilute solution to adjust the nutrient solution in the reservoir. This will avoid the pH “bounce,” which causes too much change followed by more change. Such dynamic change or “bouncing” is not good for the ions in solution, as it will cause issues such as precipitation and ion lockup.

Vinegar can also be used to lower pH, but it is not as stable as phosphoric acid.

Mixing and making hydroponic nutrients is relatively easy. Many variations of the nutrient formulas developed at University of California, Berkeley, by Dr. D. I. Arnon and Dr. D. R. Hoagland have been modifi ed and are widely used today. Here is a base formula you can use and modify to fi t your needs.

Working with a concentrated nutrient solution is most convenient. Make a 100X concentrate by mixing 10 times the amount for each “A” and “B” nutrient formulas in 2 separate containers.

| Solution | Vegetative Formula | Weight in Grams | |

| A | CaNO3 | 3 | calcium nitrate |

| A | KNO3 | 1.044 | potassium nitrate |