Separating resin glands from foliage concentrates cannabinoids into dry powdered resin glands (kief*); when pressed into blocks, the resin concentrate is called hashish or hash. Resin glands can be separated using water. Solvents can also be used to separate cannabinoid-rich resin glands from foliage. Once separated from foliage, cannabinoids can remain suspended in a solvent such as butter, coconut butter (as a food), or alcohol (as a tincture), or the solvent can be removed so that concentrated oil remains.

Resin glands are oil-based, and plant foliage is water-based. The two act differently, and this simple difference has been used for many years to separate resin glands from foliage. The first and most common form of separation is for the oily resin glands to accumulate on fingers and trimming tools. This is commonly referred to as “hand rub” or “finger” hashish.

Resin can be collected by separating it from foliage and letting it fall through a sieve. Or it can be separated from foliage using a combination of cold water and sieves.

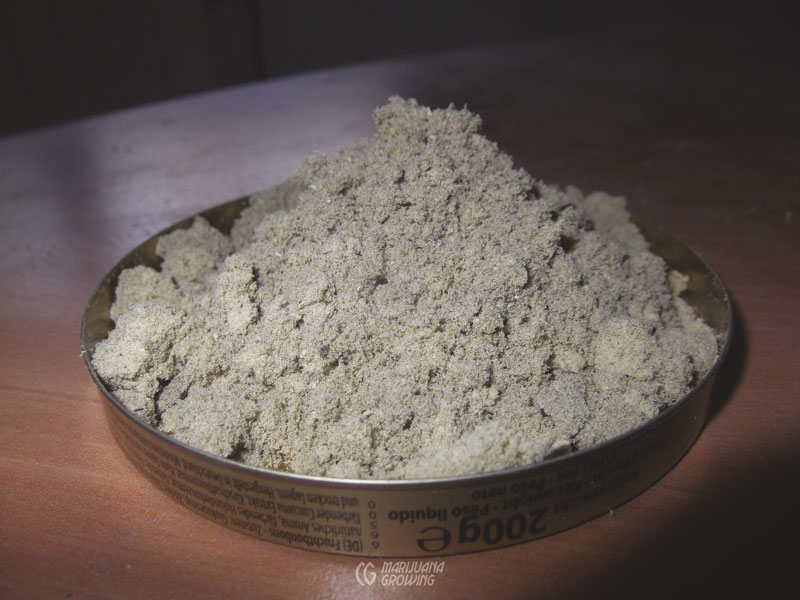

Dry cannabis foliage and flower buds can also be sieved to separate resin glands. The resin, bits of foliage, and foreign matter fall through the sieve. The resulting powder below the sieve is called kief*. Europeans often mistakenly call it “pollen.”** This golden-colored resin dust is lightweight. It can easily be collected and pressed lightly together to form a ball. Kief is pressed to form hash.

Kief consists of resin glands that are collected after passing through a sieve. Once pressed together, it forms hashish, also known as hash. The more resin in the processed cannabis, the more resinous the hashish. This chapter will touch on the basics of making hashish using safe extraction methods. Detailed information on chemical extraction methods using butane, acetate, different alcohols, and toxic dangerous solvents has been omitted because of possible health risks from explosion, fire, and fumes. Chemical damage may result from premature use of the end product before all solvents and residuals have been extracted. You can find much information on these subjects at many Internet sites.

Pollen: In Europe and other parts of the world, sieved resin powder is called pollen. The term is used because the two look similar, but resin powder is not pollen. When you hear somebody talking about “pollen,” you know they are most likely referring to resin powder.

Wet separation uses a similar principle to separate resin from foliage, except cannabis is immersed in cold water before passing through the separation screen. Once separated, wet resin is collected and dried.

Resin can also be separated and concentrated with the use of solvents such as petroleum, fats, oils, and CO2.

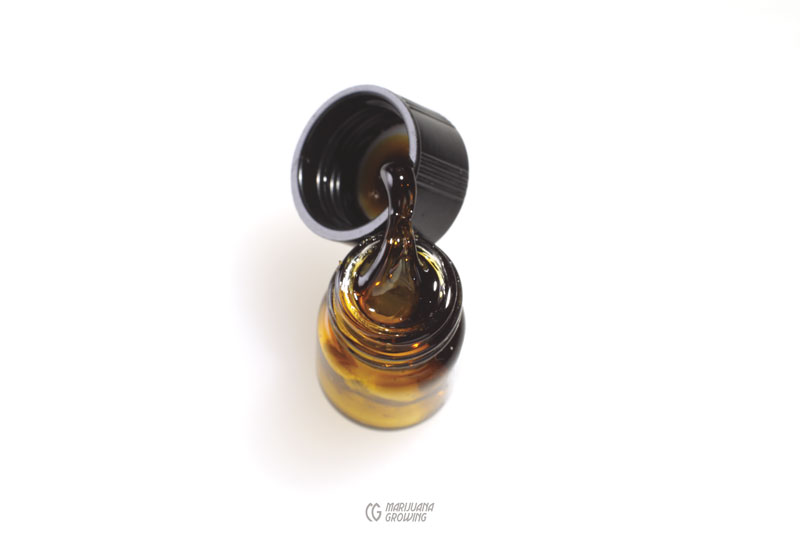

When concentrated in an alcohol or oil-based solvent, the solvent is removed, and a cannabinoid-potent liquid remains. This liquid, hash, or cannabis oil is usually very dense and increases in viscosity as it warms. The concentrate can also be manipulated with a vacuum to inject air and change the appearance of the end product.

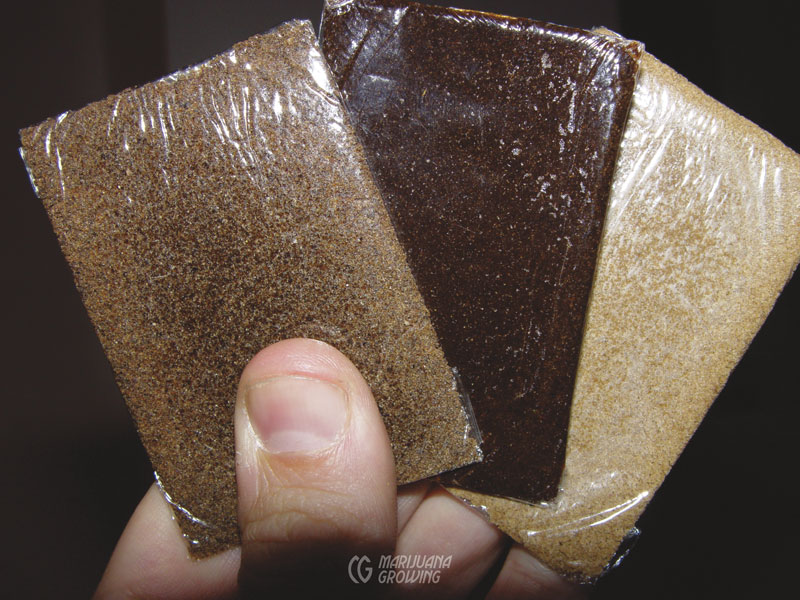

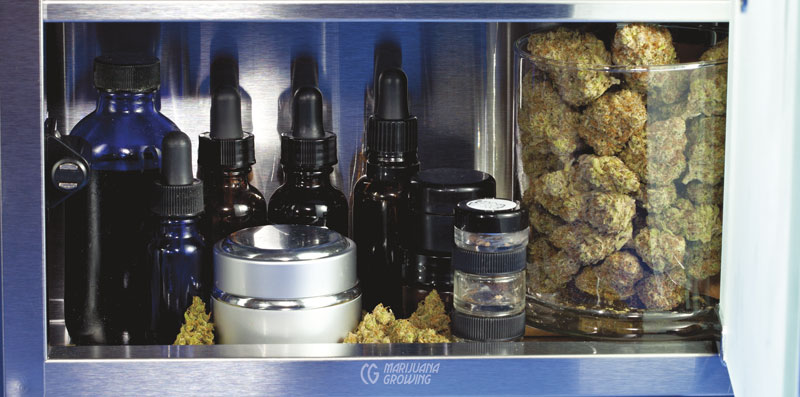

Concentrates come in all shapes, textures, and colors. Todd McCormick of Hempire Media put together this collection of fine hash concentrates that demonstrate different textures and colors.

Here are several pieces of pressed resin separated using cold water and sieves.

Once separated from buds and leaves, kief is collected.

Kief is collected and made ready to press together into hashish.

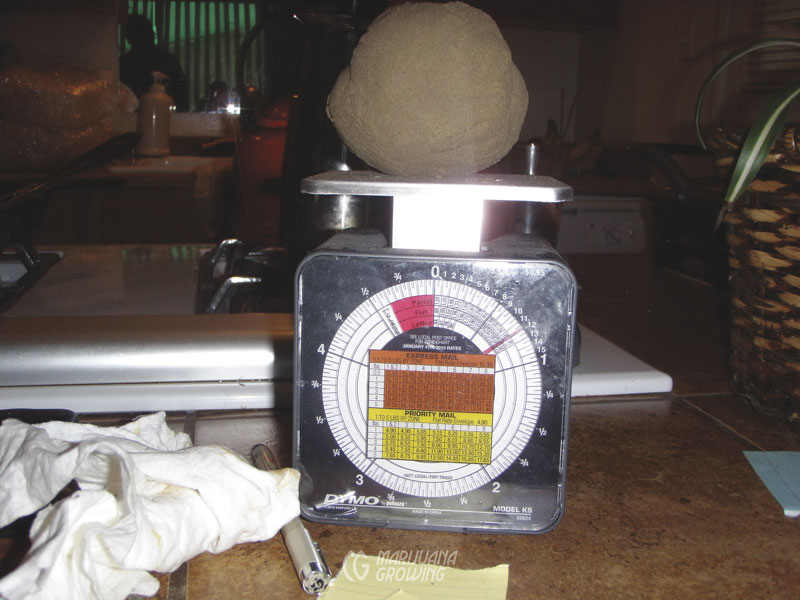

Kief was rolled into a big ball and weighs in at just under 12 ounces (340.2 gm).

Resinous water hash becomes more pliable when warm.

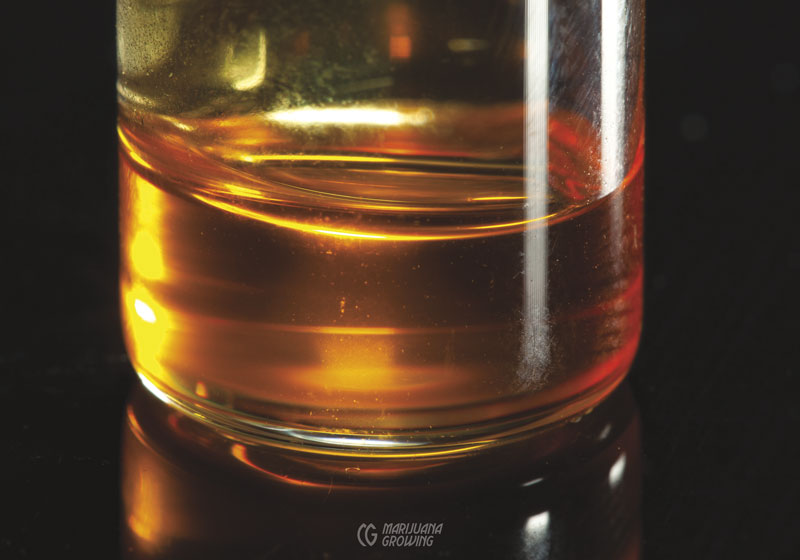

Clear amber denotes purity in concentrated CBD oil.

This bud of ‘Sour Tsunami’ is so resinous that it actually globs together.

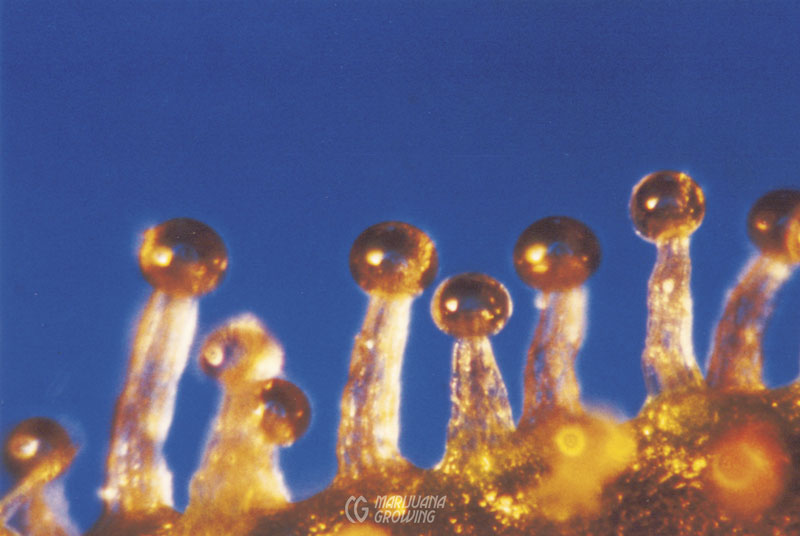

Capture resin glands with small heads by using a smaller mesh sieve.

Before Making Hashish

Make sure your plants are as clean as possible before you begin to make hashish. Remove all stems and large or damaged leaves. Any oil-based residues on leaves will show up in the separated resin glands. For example, if extracting resin with water, you can see impurity residues as sheen of oil on the surface of the water. During the month before har- vest, do not use any harmful chemicals that leave residues. To avoid potential health risks after harvest, I prefer to use only water-based organic products.

Leach growing medium with water for 5 days before harvest to remove built-up fertilizers in the soil and foliage. This will help ensure clean, sweet-tasting hash.

See chapter 9, Harvest, Drying & Cur- ing, for more on washing plants with hydrogen peroxide (H2O2) at harvest.

Freeze First: Once dry, freeze cannabis to prepare for making kief and pressing it into hashish. Place leaves in a paper bag or cardboard box in the freezer for an hour or longer. Remove them from the freezer, and use a dry or wet sieve to separate gland heads from foliage. Freezing makes it possible to collect more resin by making foliage and resin glands brittle. Cold, brittle resin glands snap off and separate easily from foliage.

The yield from 7 ounces (198.4 gm) of leaves and small buds is between 0.2 and 0.7 ounces (5.7–19.8 gm) with the average around 0.36 ounces (10.2 gm). The quantity of hash produced depends upon the quality of the original material. Clean stems, large leaves with no visible resin, dead material, and any debris from leaves and buds before making kief. Male plants do contain resin with THC but much less overall than is contained by female plants. Outdoor plants are subject to wind, rain, and dust, which may prevent resin growth or cause much of the resin to be knocked off the plant. Plants protected in indoor and greenhouse environments exude as much resin as possible. Such plants with heavy resin are best for kief-making. Great hash also comes from the closely trimmed leaves around buds.

Keep the entire hash operation clean. This is the key to keeping everything separated properly and having minimal contamination.

Yield Per Ounce/Gram of Leaf and Small Buds:

- Quantity of Leaf: 3.53 oz (100 gm)

- Dry Sieve: 0.14–0.21 oz (4–6 gm)

- Water Extraction: 0.21–0.283 (6–8 gm)

Place cannabis leaves and buds to be made into hash in a cardboard box in the freezer.

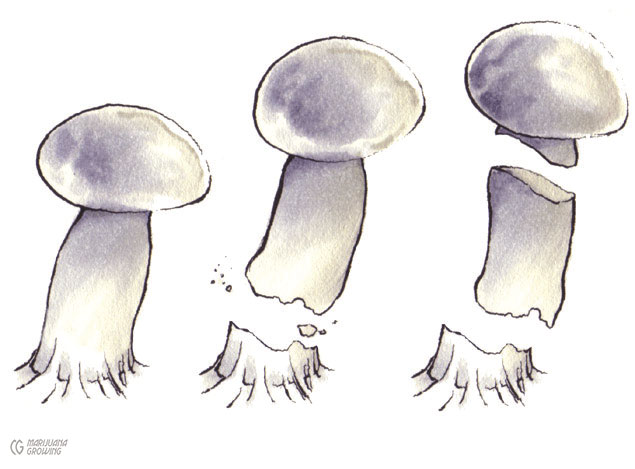

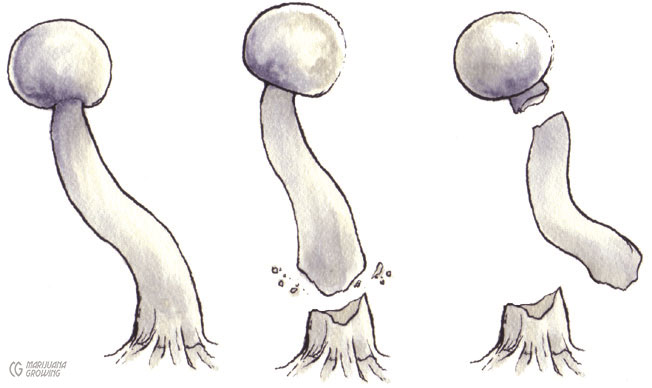

Resin glands generally break off near the bottom of the stalk and just under the round head.

Indica-dominant varieties often have larger resin heads with short, stout stocks.

Dry-separated resin is passed through sieves. It retains natural fragrances and flavors.

This big batch of resin was collected from leaves. In earlier days it would have been tossed out with the leaves!

This box of sieves makes dry-sieving cannabis easy. Each sieve below is a different size mesh to collect different grades of resin.

Dry Separation

Many hash-makers prefer dry separation because with this method the natural resin fragrances are retained. Dry-sieve kief is not as concentrated as water- extracted hash. Along with plants’ essential fragrances, dry kief retains more contaminants—plant matter, stigmas, insect parts, dirt, and so forth.

The resin is simply sifted through a sieve or a series of fine sieves. Resin heads are different sizes. With the help of different-sized sieves, you can use the differences in resin head sizes to separate them from other plant matter. Typically, a minimum of two sieves is used to make hash. The first one filters out the large plant matter and larger debris, letting the resin glands and small debris pass through to the second sieve.

The first sieve should have approximate- ly 110- to 150-micron pores. The second sieve allows small resin glands to pass, while it holds back large, mature resin glands. The pores on the second sieve should have 60- to 150-micron pores. You can find silkscreens at your local hobby and art supply store. Printing supply stores also sell framed screens.

The sieves can be stretched out flat and fastened to a frame or stretched over a cylinder to form a tumbler. (Tumblers are typically automated.)

This sieved resin from 1999 has been pressed into hashish.

| CONVERSION TABLE FOR SIEVE OPENINGS | |||

|---|---|---|---|

| US Mesh | Inches | Microns μ | Millimeters |

| 40 | 0.0165 | 400 | 0.400 |

| 45 | 0.0138 | 354 | 0.354 |

| 50 | 0.0117 | 297 | 0.297 |

| 60 | 0.0098 | 250 | 0.250 |

| 70 | 0.0083 | 210 | 0.210 |

| 80 | 0.0070 | 177 | 0.177 |

| 100 | 0.0059 | 149 | 0.149 |

| 120 | 0.0049 | 125 | 0.125 |

| 140 | 0.0041 | 105 | 0.105 |

| 170 | 0.0035 | 88 | 0.088 |

| 200 | 0.0035 | 74 | 0.074 |

| 230 | 0.0024 | 63 | 0.063 |

| 270 | 0.0021 | 53 | 0.053 |

| 325 | 0.0017 | 44 | 0.044 |

| 400 | 0.0015 | 37 | 0.037 |

| A micron = one millionth of a meter (1/1,000,000 m) or one-thousandth of a millimeter (1/1000 mm) or a micrometer or the symbol for micron “μ” | |||

Sieves

Sieves are made from woven wire, nylon (silkscreen), and laser-cut metal. Wire screens generally have wider openings and are made from various materials, including stainless steel. Nylon silkscreen is the most common sieve material used for resin separation. It is relatively inexpensive, durable, and the sizes of the small micron holes are relatively consistent. Laser-cut sieves are much more expensive and are not used by skilled hash-makers. Check this link for an example, http://www.precisioneforming.com.

In the USA, the number of openings across 1 inch is the mesh size. For example, a “5 mesh screen” means there are 5 little squares across 1 linear inch (2.5 cm) of screen. A 100 mesh screen has 100 openings.

Mesh size is not precise, relative to particle size. Screens are made with different thicknesses of wire, which causes the holes in the sieve to change size too. Wires are closer on fine-weave mesh. If the weave is too fine there is no space between wires. Sieve mesh is rated with a “–” or “+”. For example, –100 mesh aluminum means all particles would pass through a 100 mesh screen. A +100 mesh means all particles are retained on a 100 mesh screen.

The Resin Heaven from Portland, Oregon, USA, was the first rolling tray equipped with a screen to collect resin. This device has spawned countless similar products.

Make sure sieves are labeled with the micron size. Color-coding helps too.

Flat Sieves

A flat screen can be stretched taut and fastened to the frame. Find nylon silk-screen and frame at your local art supply store. Or you can also buy prefabricated screens and frames at art supply stores for screen-printing. Or you can find one through many retailers on the Internet. Always use monofilament rather than multifilament mesh. Frames of different micron sizes can be stacked on top of one another to render different qualities of kief. Do not use pantyhose or any similar filters.

To sieve, plants should be as dry as possible and cold (about 41oF [5oC]) so resin glands break off easily. Be careful not to force plant material through the sieve. Forcing will break more resin glands and smear their contents on the sieve and other plant material. The contents of these ruptured glands cannot be recovered. Normally, the largest mature resin glands fall first. They are followed by less-mature glands and debris, including pistillate hairs and plant debris. If you force too much through the sieve, much green matter passes; the resulting hash will be green and of low quality.

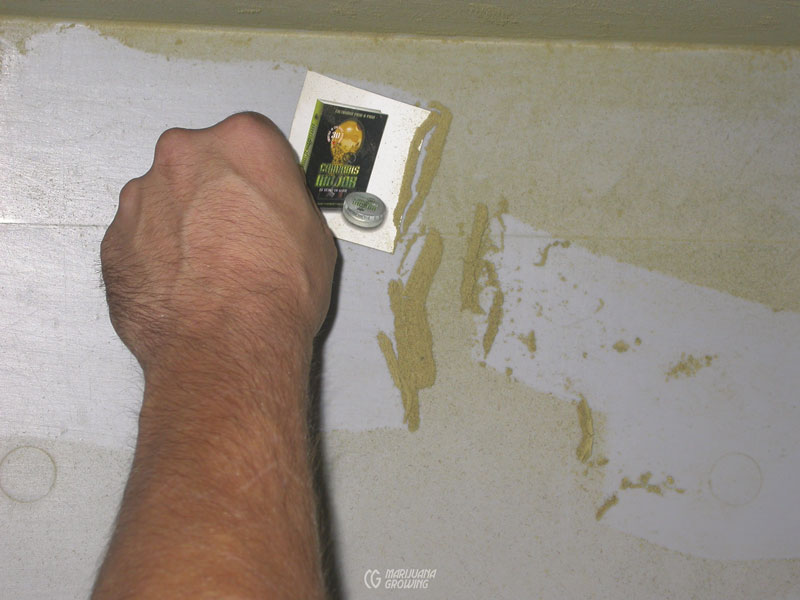

Once prepared, break up buds and foliage over a sieve, and tap the sieve lightly to jostle resin heads through the pores. You can also rub the leaves lightly on the sieve, but this will force through more green foliage and other contaminants. Resin powder will sift through the screen. The more resin on the plant material, the more resin that will fall through the sieve. Use a credit card to move the cannabis back and forth across the sieve. Exert minimal pressure on the cannabis to coax the highest-quality resin through the sieve. The first layer of powder will be the purest. Sieved hash contains more debris than most other methods, but sieving is a simple and inexpensive method to make hash.

Remember, there are several sizes of resin glands. Use the appropriate screen size to collect the most resin powder for the varieties you are processing. Fine sativa glands can be collected with a 70-micron sieve. A 110-micron sieve is the best all-around sieve, and a 150-micron sieve is best for very resinous varieties.

Sift hash through screen. Let drop onto paper with a piece of cardboard below. The dry paper and cardboard will help draw the moisture out of the separated resin glands.

Collect the powder below the sieve. Now the resin powder is ready to press into a piece of hash. Pressing generates a little heat, which also helps the resin glands and debris congeal.

These bails of Mexican cannabis were pressed tightly together and many of the resin glands were compressed and ruptured.

The bails were broken up into a powder, which further broke down the resin glands and mixed them with green matter.

This version of the 6.5-foot-long (2 m) Pollinator works great to make hash.

The cannabis spins down a long sloped tube made from fine-mesh sieve material.

Scrape the resin from the bottom of the box. Collect the dry resin, and press it into hash.

Tumbler Sieves

Mila, owner of the Pollinator in Amsterdam, Holland, and a good friend, has spent much of her life learning and teaching how to extract more resin from cannabis. She invented and popularized the Pollinator, a motorized cylindrical sieve to separate resin powder from leaf and buds.

The Pollinator consists of a drum that turns inside a box. Cold, dried cannabis is placed inside the drum that is made from 150-micron screen. A motor turns the drum, and resin glands fall through the screen as the cannabis tumbles inside. Resin is collected below the drum. Today there are several other devices that use the same principles.

Highest-quality resin falls through the screen first. Progressively lower-quality resin falls through the mesh the longer the drum turns. More green matter and other adulterants fall through the screen when the Pollinator turns for longer periods of time.

But first the dry cannabis must be pre- pared. The leaf must be bone-dry so that it does not gum up the sieve. Put super dry cannabis in the freezer for 2 hours, until it freezes. This will make the cannabis resin glands separate more easily from the foliage and make the sieving process much more efficient and productive.

Let the drum turn for 2 to 5 minutes. Use a short-range kitchen timer to avoid running the drum for too long. As the drum turns, the purest cannabinoid-rich resin falls through the screen first, onto the bottom of the box underneath the drum.

Pollinators and similar devices place cannabis in an enclosed drum that spins for a few minutes to several hours. The kief falls through the sieve and is collected afterward.

Mila, from the Pollinator in Amsterdam, hosted the Dab-a-Doo celebration in Berkeley, Cali- fornia. Jorge Cervantes is pictured on the right.

Once the process is complete, the sieve is removed and the hash remains.

Bubble Man continues to contribute to and innovate in the world of cannabis concentrates.

Making hash with one of the original Ice-O-Lator setups.

Water-Extracted Resin

Resin (glands) extracted using cold water is known as water hash, ice hash, or Ice-O-Lator hash. Very pure hash will bubble and release volatile resins when exposed to a flame, hence the name bubble-hash. This boiling effect is called “full-melt bubble.”

Mila continued to play with the sepa- ration method and refined it. Within a short time, she combined the dry sieving process with ice-cold water; the out- come was Ice-O-Lator bags. They are 3 waterproof nylon bags with progres- sively smaller micron silkscreens sewn into the bottom of each. Clean cannabis is chopped and placed in ice-cold water in the bags. The water is mixed. When the slurry settles, the resin glands pass through the screens, and the foliage and debris are retained in bags. The water is drained, and a few nice clumps of high-quality hash remain.

Bubble Man refined the process by adding more bags with progressively smaller mesh. He uses 7 different screens to sieve resin. He found that each screen separates unique sediments, some of which contain exceptionally pure THC. This hash is so pure that it bubbles when heated. Bubble Man popularized this saying, “If it don’t bubble, it ain’t worth the trouble.”

Water-soluble terpenoids found in cannabis resin contribute to fragrance and taste. The majority of these soluble terpenoids dissolve and are washed out when extracting resin with water. The result is often hash with little flavor and aroma.

Once processed and separated, residual hash is left to dry.

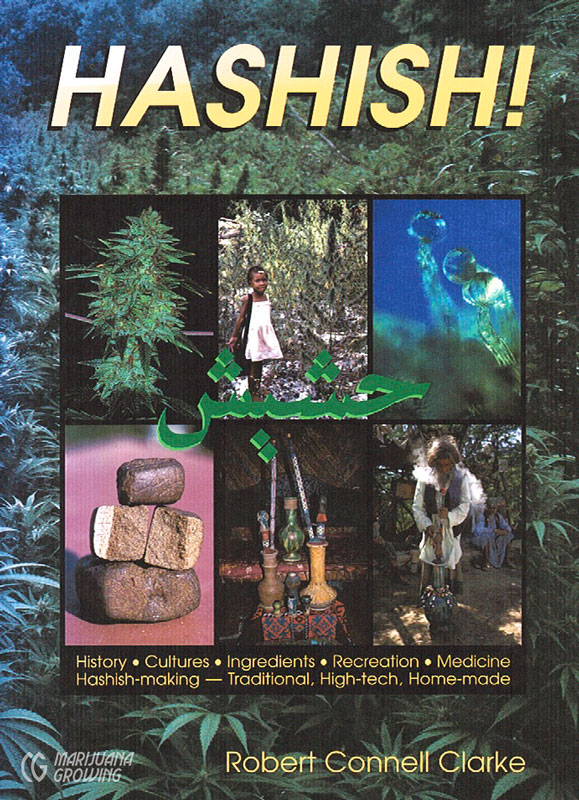

Modern water hash extraction started with “Sadu Sam’s Secret” that was published in HASHISH! by Robert Connell Clarke. Sadu Sam’s Secret is simple physics: resin is oil-based, and cannabis foliage is water-based. This difference makes separating the two in aqueous solution easy. Heavy, oil-soluble resin glands will not dissolve in water; they are heavier than water so they will sink. Water-soluble material dissolves in liquid, and foliage is lighter than water, which makes it float!

A passage from HASHISH! states, “Sadu Sam’s Secret involves stirring a few grams of pulverized flowers or freshly sieved resin powder into a tall container of cool water containing ten to twenty times the volume of water to dry powder. Cool or cold water is essential because warm water softens the resin, which tends to stick together forming an unmanageable lump. The mixture must be stirred vigorously for several minutes until the lumps of the powder disperse. Once stirring ceases, the differing particles in the suspension begin to separate. Plant particles and other light debris (such as plant “hairs”) float to the surface. Small, immature resin glands also tend to float. Mature resin glands and any dense debris such as sand and mineral dust sink, settling to the bottom.” You can still use this method to separate resin from foliage.

Now the hash is out of the bag! Many manufacturers have jumped on the bandwagon. Your time and budget will dictate how many bags you want to use for making water hash.

Use 3 bags and process the mix twice to extract the bulk of the THC-rich resin. Keep the wet plant material from the first water hash extraction. Freeze it and process again to extract more resin. Or you can use 5 or more bags in a single run and harvest different qualities, some of which are very pure.

Use leaves that have visible resin. Using large fan leaves or immature leaves will result in disappointing hash.

This method calls for a mixer with paddles. Note that paddles can bruise resin glands. If you can, find one with long shanks on the paddles for easy, deep mixing in a 5-gallon (18.9 L) bucket. You can cover the bucket when mixing to help contain splashes. However, moving the mixer around the perimeter of the slurry helps mix up any dry or stagnant places.

When you press powder, the resin crystals will break and the oil will be released. The mix will darken as it oxidizes. The resin crystals from very fresh leaf will remain white, a very high quality. For more information, see www.pollinator.nl.

For complete examples, please see Marijuana Horticulture: the Indoor/Outdoor Medical Grower’s Bible, chapter 15, Hash and Oil Making, “Ice-O-Lator Instructions” and “Water Hash with 15 Bags.”

More wet sieves separate more and different qualities of cannabis resin. Resin heads are different sizes and therefore fall through different size pores in a sieve. You can separate different sizes of resin glands with wet or dry sieves having progressively smaller sized pores.

The “work bag” is the one that contains the bulk of the processed, resinless leaf. The work bag is usually drained and set aside so the debris inside can be discarded at will. Bags with rigid sides perform better because they retain their shape inside the bucket and are easier to use when only one person is making water hash.

The hash-laden water that is left over after passing through six bags is separated again by running it through eight more bags. The resulting hash is very clean.

When starting with 100 grams (3.53 oz) of pretty good leaf from a resinous variety, using water extraction with 15 sieves, you should be able to separate out 10 to 15 grams (0.35-0.53 oz).

This synopsis was adapted from Bubble Man’s postings on www.overgrow.com (now closed).

- 25μ bag – most often full of sativa full-melt and physically the smallest bag

- 45μ bag – nice head hash, most often consistent and yellowish to white in color

- 73μ bag – full melt all the way

- 120μ bag – good bubble

- 160μ bag – best for big-headed indica glands. Debris can also settle here.

- 190μ bag – removes the majority of the big debris from the settling process

- 220μ bag – is the first filter where all the big stuff stays

Washing Machine Hashish

Using a washing machine rather than a bucket and an egg beater, to separate resin from leaf saves labor. A large machine is necessary to make big runs of water hash. A big machine saves hours of labor. Use a small machine to make runs of up to a half pound (226.8 gm).

When pressed, Ice-O-Lator resin sticks together into easy-to-manage hash.

Thank you for sharing that information. It’s impressive to see the amount of resin that can be separated from a relatively small quantity of resinous leaf material using the described extraction method. If you have any more questions or if there’s anything specific you’d like to know or discuss regarding this topic or any other, feel free to ask!

Carbon Dioxide (CO2) Extraction

In this extraction process, dry CO2 literally freezes resin glands, making them easy to shake loose from foliage.

Properly set up CO2 extraction is very efficient. Large-scale extraction would function under high pressure and have precision tolerances to get the most out of the separation process. When CO2 is used as a solvent, it requires much pressure (73.8 bar [1070.38 psi]), and the initial setup is expensive. Please see www.marijuanagrowing.com for more information on using CO2 as a solvent to concentrate cannabis resin. Most people are interested in small-scale separation.

Supercritical fluid extraction (SFE) is the most precise way to extract not only cannabinoids, but essential oils as well, and is a means of separating different elements of botanicals. Herbal essential oils, hops for beer, pharmaceutical precursors, and decaffeinated coffee are all processed using SFE.

The supercritical fluid extraction method forces a solvent (CO2) through plant matter under high pressure. When the solvent is pushed through the plant matter at such high pressure, it can separate the matter precisely, allowing us to isolate only the purest essence of our botanicals, in this case, cannabis. The result is pure, transparent, amber oil.

Supercritical CO2 has high diffusion rates which allow it to penetrate solids faster than a liquid solvent. Naturally occurring carbon dioxide leaves no residue. Other popular solvents used to extract resin, such as butane, can leave heavy metal residues in the extracted resin.

See http://en.wikipedia.org/wiki/Supercritical_carbon_dioxide

Dry ice is solidified CO2 gas. When frozen, CO2 is super cold and must be kept in a special freezer that is even colder. It sublimes (transforms from a solid to a gas) and evaporates into the atmosphere. Dry-ice extraction freezes off resin glands. The frozen glands fall through a 120 to 220 mesh sieve and are collected below.

A 5-pound, solid piece of dry ice costs $15 to $20 USD. If kept in a freezer overnight, dry ice will lose up to half of its weight. For most people, using frozen CO2 to separate resin is too expensive to be practical. And it is so cold that it can burn skin on contact. Always handle with gloves.

Dry ice is easy to use. Cover a 5-gallon plastic bucket with a 120 to 220 mesh sieve Bubble Bag normally used to make water hash.

The final product can be of many grades. The first few shakes will yield the highest quality. The smaller sieves (120, 160, etc.) let less green matter through. Larger mesh (200, 220, etc.) lets a lot through!

Always shake over a large, flat mirror or large, smooth surface. Such an area makes it easy to scrape up kief.

Dry Ice Kief: Step-by-Step

Step One: Place a few chunks of dry ice in a can or container. Add about 3 times as much leaf and small buds to the container with the dry ice. Let the pieces of dry ice mix with the pre-chilled cannabis so that it freezes resin glands. The cannabis should be as intact as possible. Do not grind it up.

Step Two: Place a Bubble Bag (or something similar) with a 160 mesh sieve at the bottom over the container. The sieve end of the bag should cover the container opening. The bag may fit completely over the container. Secure the bubble bag so its screen is taut over the opening.

Step Three: Shake the CO2 cannabis mixture in the can so the chunks of dry ice break up and freeze the pre-cooled cannabis.

Step Four: Turn the container upside down so the sieve is facing the mirror below. Shake the container for a few seconds or up to 5 minutes. White vapor emerges from the container as the CO2 sublimes and resin glands slide through the sieve onto the mirror.

The first couple of shakes you’ll get top-quality resin glands. The resulting powder progressively turns to green leaf matter. Shake the container a few times so that the highest-quality kief passes through the sieve. Collect this kief before progressing to the next grade. Repeat the process as many times as desired.

Step Five: Remove any remaining pieces of dry ice. Scrape kief from the sieve and inside the container onto the mirror. Scrape kief that fell through the sieve into a pile. Store the kief in a glass container and use it for cooking. The hash is lower quality and contains contaminants, but the cannabinoids are concentrated in the final product.

In simple experiments, this method yields 15 to 18 percent or more final kief. As with any kief, the end product is contingent on the original buds. Resinous buds make the best kief, while lower-quality leaf and buds make lower-quality kief. This process is an easy way to store large quantities of leaf and small buds that might otherwise go to waste.

Storing Separated Resin

Make sure hash is completely dry before storing. Moist hash contracts fungus easily and decomposes quickly. Decomposition decreases THC levels. If you make hash using ice and water, be careful to dry it well. Dry by pressing the water hash into a flat pancake that has much surface area. Leave the pancake out in an arid room for a few days to dry completely. Cover the hash with a papertowel so dust does not contaminate it. If you made hash with a dry method such as sieving, you should not have to take any extra precautions before storing, unless you are working in a humid climate.

My favorite way to store high-quality water hash is to put it in a glass tube. This way all the resin stays intact until it is consumed. Upon smoking, you should press it a little so it will burn evenly. Store hash in a cool, dark, dry place. Keep in an airtight container with a packet of silica crystals. You can also put hash in the freezer for long-term storage.

For a complete account of the history and detailed methods of production, see HASHISH! by Robert Connell Clarke, (Redeye Press, 1998), www.fsbookco.com. If you want to make the best hash and have a springboard to launch into advanced processes, this is the book for you!

Semidry water hash is passed through a strainer to help remove moisture locked inside larger pieces.

Once resin passes through the large sieve, it is collected and left to dry in containers for a few days.

Dry resin is pressed into slabs. The two dark pieces in the middle top contain the most resin.

Pressing Hashish

Once collected, kief (resin powder) is often pressed into hash to facilitate handling and storage. Bulky resin powder is awkward to handle. It is easily spilled, blown away, or contaminated by dust and dirt. Kief is also more difficult to smoke, especially if no screen is available.

Once pressed into a piece of hash, however, the resin is easy to handle, store, transport, and consume. Proper pressing is essential for easy handling, storage, and to slow decomposition. Pressing determines how hash will burn and also affects taste and smell.

Small amounts of hash can be pressed by hand (hand rub); larger amounts will need to be pressed with an object such as a bottle or rolling pin. Mechanical presses are able to apply more pressure. Hydraulic presses apply the most pressure to make larger pieces.

Pressing hash creates heat that fuses resin glands together. Heating resin with a hair dryer is not necessary with pure resin. If heat is applied, a drop or two of water or alcohol can be added while pressing to make less-pure hash stick together in a block. The idea is to heat the hash a little but not melt it, keeping the heat level constant. This will help the resin bond together.

Regardless of how the resin glands are pressed, they must be contained in cellophane plastic. The cellophane is essential because the resin does not stick to this type of plastic. Do not use more durable plastic found in Ziploc bags or the resin will stick to it. Use inexpensive cellophane.

Mechanical presses must be precise and align well so pressed hash does not ooze out seams of cellophane bags. When pressed, heat and friction cause the outer layer of pressed hash to oxidize and turn darker than the interior. In fact, hash can have a dark exterior and a blonde interior packed with creamy resin glands.

Pressing Small Amounts of Hashish

By hand pressing, you experience the transformation of the resin powder into your very own piece of fragrant, dense hash. To hand press, collect one to four grams of resin powder in the palm of your hand and apply pressure to the powder, working it between the palms of your hands. Also push your thumb into your palm full of resin powder to work it into a piece of hash. Continue this process for 10 to 30 minutes until the piece of hash is completely pliable and whole. Heat will be generated and help rupture and meld the resin glands together. Relatively pure resin powder will congeal faster than less-potent powders that contain impurities. But a little vegetable matter and debris gives hash different flavors and more body.

Potent resin powder is a creamy white to gold in color. Pressing the powder together and working it in your hands ruptures and oxidizes resin glands, which makes the mass turn ever darker.

A small hand press makes nice little hash wafers.

Here are three different kief collections pressed into hash, still in the cellophane bags used for pressing. Make sure to pre-press water-extracted hash in a piece of cellophane to contain it and help get rid of the water. The cellophane will give the pressed hash a shiny skin.

This piece of “finger hash” was scraped from fingers and trimming tools in a single day of trimming!

Hand-Rub Hash

Hand-rubbing hash is simple and easy but inefficient and wasteful. All you need are a good pair of hands, adequate cannabis buds, and desire. However, much of the resin falls to the ground or gets lost within the buds, and it may stick to other foliage. Overall, hand-rubbed hash is lower quality and contains more debris compared to sieved or water-extracted hash.

Hand-rubbing is most common in the Himalayan foothill regions of Nepal, India, and Kashmir, where “charas” (the Indian word for hand-rubbed hash) is fairly popular. Most small-scale and commercial growers collect the little bit of hash from their hands and tools during manicuring. This is the closest thing to hand-rubbed hash that most growers experience.

Plants that are best suited to hand-rubbing have sticky resin that adheres to hands better than it sticks to other foliage. At the same time, the resin must be relatively easy to roll into little balls to remove from hands.

Collect hand rub from healthy, strong, mature plants with green leaves. Some large leaves may already have started to turn yellow. Remove brown, crisp, and dead foliage before rubbing. Remember, cannabis plants are generally pretty tough and can take vigorous (but not abusive) rubbing.

Once collected on hands, resin must not be allowed to collect other debris or foliage. Any foreign matter that sticks to resin-laden hands should be able to be brushed off easily.

Gather resin by rubbing individual flowering branches firmly between hands. Slowly move hands up from the bud, continually rubbing back and forth.

Rub palms and fingers in between resin-covered flower clusters so they come in contact with as much resin as possible. Each branch should be rubbed for 20 seconds or more. After rubbing a few branches, you settle into an intoxicating, hypnotic rhythm. Aromatic fragrances are released as you rub the buds.

Small pieces of resin accumulate on hands, gloves, and trimming tools. This resin is scraped up and consolidated.

Once in hand, the small pieces of resin are molded together. The body heat generated by the hand and light pressing melds the small pieces together.

After a few minutes of handwork, the pieces of hand-rub hash form a spherical ball that is easy to store, transport, and use.

The resin sticks to hands slowly at first, but once they are covered with a light sheen of resin, the accumulation process speeds. Brush off any foliage or debris from hands as soon as it sticks so the resin remains reasonably pure.

To remove the resin from hands, rub your palms together so resin clusters together into sticky little balls. At first the resin will ball up relatively quickly. Lump the balls together to form a single piece. Use this piece to rub on resin that is still on your hand to help remove it. If hands are moist or sweaty, soak up moisture with a paper towel before removing hash.

Once collected, knead resin in your hand until it reaches your desired consistency. Hand-rubbed hash is best enjoyed within a few weeks of collection. Collecting hand-rubbed resin is time-consuming. An average collector can rub all day and collect a mere 5 to 10 grams!

Bottle Pressing

Press small amounts of resin powder between cellophane to form a pancake. Fill a long cylindrical bottle with warm water and use it as a “rolling pin” to press the pancake of hash. The extra heat from the warm water will help loosen and blend the kief into hashish.

Use a laminator—the kind that overlays photos and documents between 2 sheets of plastic—to press hashish. Sprinkle the best resin powder, kief, you can make onto a piece of cellophane. Lay another piece of cellophane on top. Roll over it with a bottle full of warm water to get it into preliminary shape and make it easy to work. Remove the piece of hash from the cellophane; treat it like you would a document and laminate it. Laminating machines usually have a heat control that helps with pressing hash.

Use a bottle full of warm water to press resin powder between two pieces of cellophane. The heat and pressure from the bottle will heat the resin so that it sticks together. The cellophane keeps the resin in place during pressing and serves to protect the hashish afterward.

These thin pieces of potent hash were pressed between cellophane using an office laminator.

Add a little heat to hard-to-press hash that contains impurities. The heat will help the mass congeal so bricks do not need excessive pressure to stay together. But remember that pressing also increases heat; do not heat the resin too much or it will be damaged.

Mechanical Pressing

Place resin powder in a plastic bag or cellophane wrapper to contain it while pressing. All the powder will be pressed within the wrapper into a brick or plaque of hash. Poke a few small pinholes in the bag before pressing to allow trapped air to escape. The bag is placed into a heavy-duty steel mold, and pressure is applied with a hydraulic jack. Hydraulic jacks have a capacity from 10 to 20 tons and are mounted to heavy-duty steel frames that normally contain a 100-gram mold.

The pressure exerted to form a cohesive block is contingent upon the volume of contaminants in the powder. The more pure the resin powder, the less pressure it takes to form it into a block.

If your hash was made with water, make sure it is totally dry before pressing, to avoid mold. Water hash does not react like dry-sieved hash when pressed. Resin has been melded together in a different way than dry powder. Pressing the resin when it is wet will trap moisture inside the hash. The hash will not dry completely, and it will not properly gel together later. It will retain a powdery consistency.

Dry-sieved resin powder will press easily and stay together under lower pressure when it is relatively pure. If it is adulterated with impurities, more pressure and heat will be necessary to press it into a block.

You can also add a drop of alcohol in the form of brandy, whiskey, bourbon, rum, etc., to help meld the glands together. Spirits with higher alcohol content are favored. Be careful to add only a drop at a time; alcohol takes a few minutes to completely penetrate and act.

Use a hydraulic press to press larger amounts (50–100 gm) of kief into hashish.

Hammering Hashish

Hammering hash is a popular pressing method in Morocco but uncommon elsewhere. Hammering bursts and blends resin glands together into a cohesive mass.

Often resin glands are hammered before being hydraulically pressed into plaques.

To hammer hash, pour resin powder into an extra-heavy-duty plastic bag. Place the bag on a wooden board and top it with another board. Whack the board with a hammer until the resin powder forms a cohesive pancake. Remove the hash from the bag and fold once or twice to make it smaller and thicker. Repeat hammering and folding until resin glands transform into a sticky piece of hash. Hammering will heat the resin, but apply a little heat if the hash is slow to form.

Online resources: Supplies and equipment for making kief or water hash:

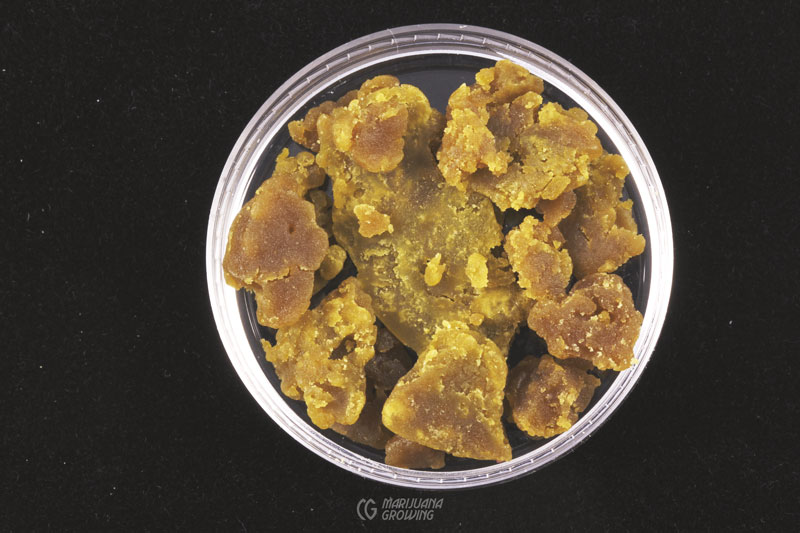

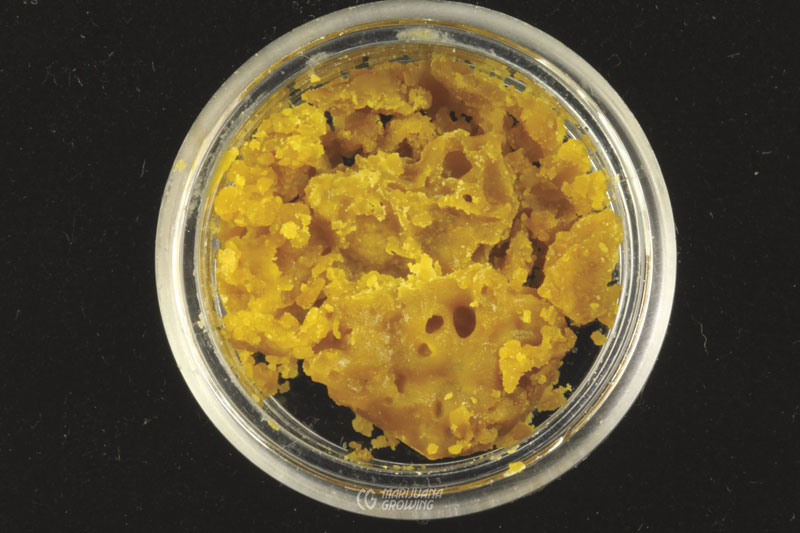

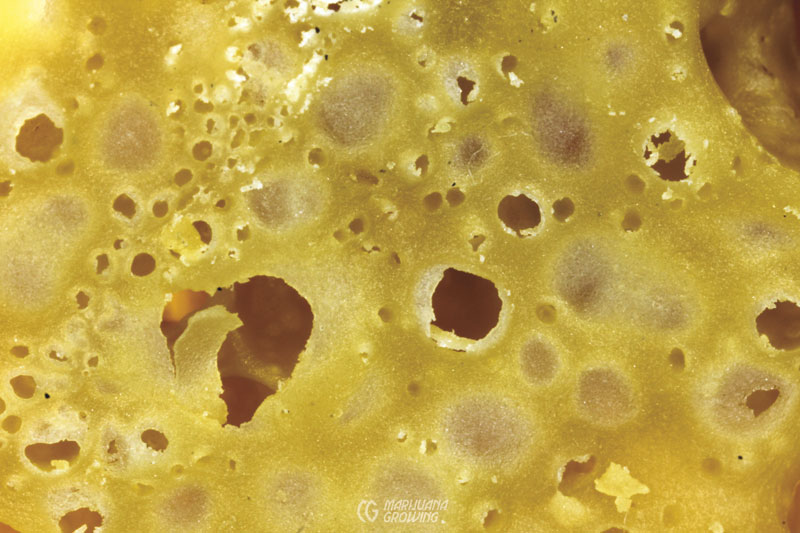

Granddaddy Purple’ (left) and ‘Head Cheese’ (right) are two examples of “wax” — concentrated resin containing cannabinoids that have been extracted with a solvent, usually butane. Harmful residual chemicals from butane hash oil (BHO) are purged by placing it in a vacuum under controlled conditions. Texture, color, and structure of the wax are governed by the duration and exposure to vacuum pressure and heat.

Concentrated Cannabis Resin

Hash oil is a concentrate of hash or cannabis (cannabis oil) that has been dissolved in a solvent. The ingredients are combined, the mix “cooks” for a time, and the cannabinoids are later separated from the liquid solvent. The solvent is usually removed by evaporation, leaving concentrated cannabis. Impurities can be filtered, but the process takes longer.

More if not all residual butane, other solvents, and impurities can be purged in a vacuum chamber. Once purged of impurities, concentrated resin takes on a new texture and is often referred to as wax, earwax, budder, shatter, and crumble.

Nasty hydrocarbon solvents such as ether and alcohol are used to extract cannabinoids. When improperly processed, cannabis, hashish cannabis, and hemp oils retain residues from solvents used to extract cannabinoids. These residual solvents are often locked in chemically. Such solvent residues pose a health risk. The residual is a sludge that contains chlorophyll, plant waxes, other debris, and cannabinoids. These residues are a health risk when inhaled. I do not recommend volatile solvent extraction because it requires the use of dangerous chemical solvents.

Explaining in detail how to make solvent-based cannabis concentrates and oils is beyond the scope of this book. I do not like such concentrates because the residuals are often difficult to remove. There are numerous videos on YouTube and website forums that explain in detail many of these processes.

Hydrocarbons are released when using petroleum products to extract resin. The process is usually finalized by boiling or evaporating off the solvent. Ventilation must be adequate, and the heat source should be electric. An open flame is out of the question. Fire and explosions are a reality!

Cannabis oils can be very concentrated and potent. Honey oil was popular in America in the early 1970s. The oil was a translucent golden-amber color. The oil transformed from stiff, toffee-like consistency to runny oil when warmed. Today there are many different cannabis and hashish oils.

Cannabis oils that are greenish in color contain chlorophyll, while dark colors signify other contaminants. Filtering the oil through charcoal can remove most of the impurities. Hashish oils never became super popular because they are inconvenient to consume, and many people do not want to be exposed to the health risks associated with the solvents used for processing.

Making cannabis oil is easy, though. First the solvent and cannabis are combined. Next the cannabinoids migrate chemically to the solvent. This could take a few minutes to a couple of months. Later the solvent-laden cannabis mix is placed in an open container to evaporate. Once the solvent is completely evaporated, the concentrated cannabis oil remains.

Solvent efficiency is dictated by its chemical properties and purity. Overall the polarity of a solvent determines what it is able to dissolve. Solvents are polar, nonpolar and semipolar. Extract cannabinoid molecules only with nonpolar solvents. Nonpolar solvents dissolve only oil-based resin and the resulting concentrate is a rich honey color. Polar solvents extract only water-soluble plant material molecules including chlorophyll. Semipolar solvents extract oil-soluble cannabinoids and water-soluble plant material. The contaminants—water soluble plant material including chlorophyll—cause a green color and taste. Impurities include water and commercial additives combined with the solvent during manufacturing and can be an issue with industrial solvents.

Butane and hexane are non-polarity solvents and extract only cannabinoid molecules. Butane and hexane are the most common solvents used to make concentrated cannabis oil.

Isopropyl alcohol, methanol alcohol, and ethyl alcohol are all semipolar solvents and extract both cannabis resin and plant material. A higher concentration of alcohol with few contaminants will extract the greatest amount of cannabinoids. For example high-grade ethyl alcohol (95%) has only 5 percent water to dissolve plant matter.

Boiling extract mixes to remove solvents from concentrate almost always leaves solvents locked in residuals.

Golden Buddha oil is a popular concentrate at California medical cannabis dispensaries.

Hash oil has a high concentration of cannabinoids.

Solvents

Butane (nonpolar)

Severely hazardous Very flammable Highly explosive Boiling point: 31.1oF (-0.5oC) Flash point: -76oF (-60oC)

Butane is a non-polar solvent that does not dissolve plant material. Butane hash oil (BHO) is made by passing butane gas through chopped cannabis in an enclosed container. Butane dissolves cannabinoids very quickly. The liquefied, butane-laden cannabis resin mix is carried by gravity out the drain on the lower end of the airtight receptacle. The liquid is collected in an open bowl.

Dangers and Safety

The boiling point is the temperature at which a liquid boils and turns to vapor. The flash point of a flammable liquid is the lowest temperature at which it can form an ignitable mixture in air. At this temperature, the vapor may cease to burn when the source of ignition is removed.

The fire point is defined as the temperature at which the vapor continues to burn after being ignited.

Note: The ideal solvent has a high flash point and a low boiling point.

Solvent must have a lower boiling point than the residual cannabis resin (380oF [193oC] and CBD at 320oF–356oF [160oC–180oC]). Solvents with a boiling point greater than the highest temperature achieved will remain in the concentrate! DO NOT USE!

The chemistry of solvent separation is complex. For example, butane may refer to either of two structural isomers, n-butane or isobutene (methylpropane), or a mixture of the two “butanes.” The flash point of isobutene (i-butane) is higher than n-butane. As isomers, n-butane and i-butane have the same chemical formula but different structures and do not always share the same properties.

Research each chemical you are considering using to extract cannabinoids. Check all chemistry, hazards – flammability, health warnings, etc. Here is a good place to start: www.engineeringtoolbox.com.

The butane is then allowed to evaporate into the air. Setting the bowl in a pan of warm water will speed evaporation. Once the butane has dissipated completely, the residual, honey-colored oil can be scraped from the bottom of the glass collection pan.

Butane lighter fluid refill cans are the most common source of this solvent. It is relatively inexpensive, easy to find, and very fast-acting. Avoid brands that contain additives.

Caution! Butane gas is very flammable. Be extremely careful when using it. Use only in a well-ventilated area and never around an open flame, sparks, or anything that might ignite it. Wear protective gloves and a breathing mask when handling butane. Avoid contact with skin and body parts.

To Make Butane Hash Oil

Step One: Fill a 1-quart (1 L) plastic beverage container with chopped cannabis leaf or flower buds. (Higher-quality cannabis contains more cannabinoids and will render higher-quality hash oil.) Do not pack cannabis too tightly in the container. Butane needs airspace to be able to penetrate all the cannabis quickly.

Step Two: Poke a small hole in the bottom of the container and insert the fitting provided with the butane cans.

Step Three: Cut a small hole in the cap of the container. This is where cannabinoid-laden oil will exit into an open bowl below.

Step Four: Move outdoors. Do not stay indoors to complete this project! You will be working with very volatile butane under pressure. It is extremely flammable and requires much ventilation. Do not have any lit cigarettes, barbeques, or any open flames within 50 feet (15.2 m) of the project. Turn the container upside down and start filling it with butane fuel.

A 10-ounce (29.6 cl) container of butane will extract cannabinoids from a half-ounce (14.2 gm) of cannabis buds, trim, or shake. Always use premium-grade pure butane with no additives.

A small vial of butane hash oil (BHO) is very concentrated. Almost all homemade BHO contains unhealthy residuals.

Step Five: Place the cap of the container over an open bowl so that solvent drains out the hole and into the bowl. When the last can of butane has run through the cannabis, the solvent is ready to evaporate.

Step Six: Butane in an open bowl is very volatile and must be kept away from open flames, lit cigarettes, etc. The project should be completed outdoors to provide adequate ventilation to carry away toxic fumes. Evaporation can be natural over time. Set the bowl in a safe, well-ventilated place outdoors, and the solvent will evaporate within a few hours. Or (still outdoors) set the bowl in a pan of water on an electric skillet for faster evaporation.

Step Seven: Once all butane is evaporated, collect the oil by scraping it from the bottom of the glass bowl. A flat-bottomed glass or Pyrex bowl is much easier to scrape than one with a round bottom.

Caution! Making butane hash oil is dangerous. Fumes are toxic, and a small flame or spark will make the butane explode. Butane hash oil must be made in a well-ventilated or outdoor location.

Jelly hash is a mix of high-quality hash and cannabis butane oil. The recipe is as follows: 8 parts hash and one part butane hash oil. Dark jelly hash is sticky, oily, and difficult to handle.

Caution! Do not use a pressure cooker to make cannabis oil. Solvents do not react like water under pressure. Solvents under pressure may explode.

Other methods: Bathe cannabis in solvent, then squeeze out the solvent and let it evaporate from the solvent/cannabinoid/plant material mix. Once evaporated, the remaining cannabinoid and plant residue mix can be extracted again with another solvent that will remove water-soluble contaminants.

Hexane (nonpolar) Hazardous Flammable Highly explosive Boiling point: 177.8oF (81oC) Flash point: 0.4oF (18oC)

Hexane is made by refining crude oil. It is inexpensive, but it can be hard to find. It is often available in paint stores. Even though it is highly flammable and slow to evaporate, hexane is commonly used to make concentrates.

Petroleum Ether

Petroleum ether is also known as benzene, VM&P Naphtha (varnish makers’ & painters’), petroleum naphtha, naphtha ASTM, petroleum spirits, X4, or ligroin (semipolar) Hazardous Very flammable Highly explosive under pressure Boiling point: 100.4oF (38oC) Flash point: <0oF (<-17.8oC)

Petroleum ether is a very selective solvent. To minimize danger and cut costs, petroleum is first extracted from the cannabis with alcohol and re-extracted with petroleum ether. Petroleum ether is available at hardware stores in most countries. Do not confuse petroleum ether with diethyl ether. The term “ether” most often refers to diethyl ether. Petroleum ether has a specific gravity of between 0.6 and 0.8, depending on its composition.

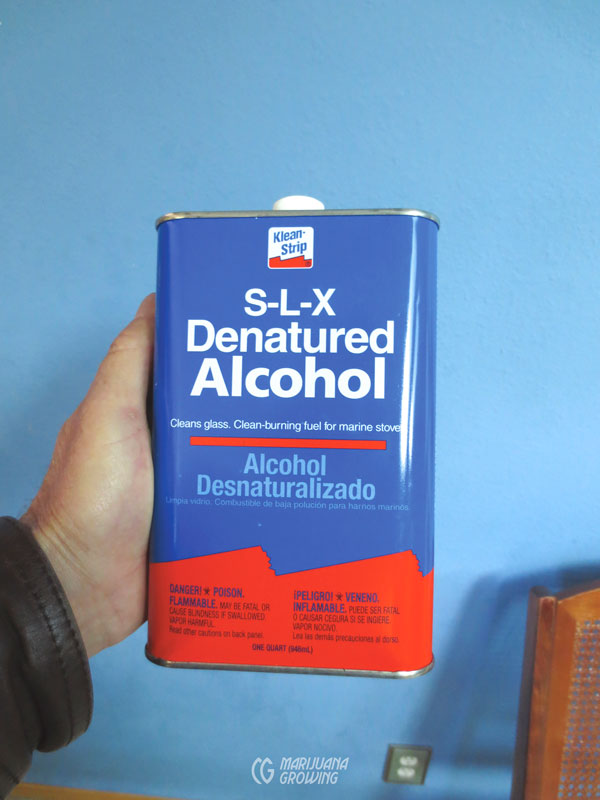

Do not use denatured alcohol!

Rubbing alcohol is easy to find at any pharmacy or supermarket.

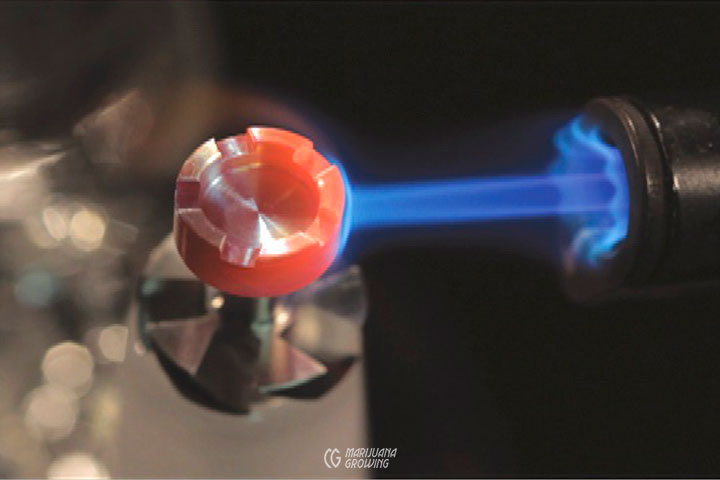

The torch heats the bowl red-hot before a small piece of hashish or oil is dropped or “dabbed” in.

Acetone

Severely hazardous Very flammable Highly explosive under pressure Boiling point: 132.8oF (56.1oC) Flash point: -4oF (-20oC)

Acetone is readily available and sold as a solvent or degreaser and as fingernail polish remover. Do not use acetone mixed with other chemicals. It evaporates rapidly and is generally recognized as safe to use. It has low acute and chronic toxicity if ingested or inhaled. It is rated as a GRAS (generally recognized as safe) substance for food use.

Acetone is very flammable. Tempera- tures above acetone’s flash point of -4oF (-20oC) and an air mixture of 2.5 to 12.8 percent acetone by volume, may explode. Vapors can drift for distances to ignition sources and flash back. Acetone is too dangerous for safe use. Acetone’s boiling point is 132.8oF (56.1oC).

This solvent has relatively low acute and chronic toxicity if accidentally inhaled or ingested.

Ethanol / Ethyl Alcohol /

Grain Alcohol

Hazardous Flammable Explosive under pressure Boiling point: 173oF (78.3oC) Flash point: 53.6oF (12oC)

Purchase high-percentage (high proof) ethyl alcohol at liquor stores. Look for Everclear that is 95 percent alcohol (190-proof). If this is not available, use 151-proof rum (75% alcohol). A higher- proof alcohol means less residual water content. Oil made from ethyl alcohol is dark or greenish in color because it dissolves water-soluble plant material as well as cannabinoids.

The easiest way to infuse cannabis into ethyl alcohol is to place flower buds in bottles of brandy, rum, vodka, gin, or various liqueurs. Always find the most potent alcohol—the highest percentage or “proof,” which is half the percentage (i.e., 80-proof is 40% alcohol).

The bottle of 151-proof rum started life as one fifth of a gallon (0.8 qt [757 ml]) and 1.8 ounces (50 gm) of manicured cannabis buds. (Some liquid is displaced as the cannabis is added to the bottle.)

The dry buds suffered being squeezed through the neck of the bottle. Many broke up. The good news is that they are inside the bottle, soaking up the 151-proof alcohol.

Buds were as dry as possible, with few stems, all of which contain moisture that dilutes the ability of the alcohol to absorb cannabinoids. Alcohol can be evaporated so that a potent concentrate remains. However, when using beverage alcohol as a solvent, the alcohol serves to hold the cannabinoids and make a potent elixir.

Cannabis concentrates are often consumed in a titanium bowl heated with a torch. A little “dab” of concentrate is placed on the hot metal to immediately smoke and burn.

Isopropyl Alcohol / Isopropanol—Rubbing Alcohol (moderately polar)

Hazardous

Flammable

Explosive under pressure

Boiling point: 180oF (82.2oC)

Flash point: 53.6oF (12oC)

Rubbing (isopropyl) alcohol is easy to find in a 70 to 99 percent concentration. Isopropyl is highly toxic to ingest. When used to extract there is almost always residual solvent in the concentrate. This alcohol dissolves THC, other cannabinoids, and plant fiber. It makes dark-green oil that contains water, and water-soluble substances are also extracted. Cannabis oil extracted with isopropanol is sometimes referred to as “ISO (oil)”. Re-extract the oil later with a more selective solvent to remove impurities.

Once most of the alcohol is evaporat- ed, the water and remaining isopropyl alcohol that were in the solvent remain with the oil. Terpenes and aromatics are also destroyed. This solvent is less toxic and explosive than methanol, but it is flammable! Be careful when handling.

Methanol / Methyl Alcohol / Wood

Alcohol (moderately polar)

Hazardous

Flammable

Explosive

Boiling point: 149oF (65oC)

Flash point: 53.6oF (12oC)

This popular solvent evaporates at approximately 149oF (65oC) with a boil- ing point of 149oF (65oC). It dissolves cannabinoids and plant material to make green-black oil. Methanol (as stove fuel and paint thinner) is easy to find at paint stores and hardware stores.

This solvent is toxic and explosive. Fumes are toxic to inhale. Any traces of methanol in the oil are extremely hazardous to the consumer.

Denatured Alcohol

Severely hazardous

Very flammable

Explosive under pressure

Boiling point: 173.3oF (78.5oC)

Flash point: 57oF (13.9oC)

This very toxic solvent has extraction properties similar to methanol. Poison is added to denatured (ethanol) alcohol to lower the beverage alcohol tax and discourage consumption. Do NOT drink denatured alcohol! It is more widely available and is cheaper than poison-free ethanol, but the denaturing agent MUST be removed. Depending on what type of poison is used to create the denatured alcohol, the poisons are impossible to completely remove from the alcohol with evaporation.

Caution: Do NOT use denatured alcohol as a solvent!

A small amount of concentrated hashish is placed on a stainless steel pipe screen and ignited. Within a second, the concentrated hash melts and bubbles.

DJ Short Blueberry Tincture is unique in the medical cannabis industry in that it is one of the few tinctures that has the ingredients printed on the label.

The total cannabinoid content is fully decarboxylated including whole plant terpene profile: 11.24 mg per 1 ml dropper full: THC: 10.11 mg, CBD: 0.73 mg, CBG: 0.40 mg (sCFP/CO2)

Cannabis tinctures are becoming very popular at medical dispensaries. Avoid products that do not show a “guaranteed analysis.

Consuming Cannabis Oil

Cannabis oil can be wiped on joint papers, cigarettes, pipe screens, and hot knives. A popular smoking method is to smoke it in an oil pipe—a stem with a glass bubble on one end. A little oil is placed inside the glass bubble. When heat is applied, the THC vaporizes and is inhaled through the stem.

You can find out more about these processes on many Internet cannabis sites.

A new and popular method to consume such high-potency oils and resins is to place them on a piece of titanium and heat it super-hot. The resin or oil volatize immediately at 428oF (220oC); the rest is overkill but looks cool! However, there may be a health risk. Superheating titanium may give off unpleasant chemical substances. More study is necessary.

Cannabis oil can be placed in a vacuum container and over time of turning on and off the vacuum, air is infused into the oil and removed. The process causes oil to turn a golden yellow in color with air holes interspersed. The resulting material is known as “earwax.

Tinctures

11.24 mg per 1 ml dropperful

THC 10.11 mg

CBD 0.73

CBG 0.40 mg

{sCFP/CO2}

Suggested dosage on the DJ Short Blueberry Tincture label is: 5.5 mg or 0.5 dropper every 4 hours. Protect from light and heat and store at room temperature

The following text was extracted from “Marijuana Tincture Recipe, How to Make Cannabis Tincture” by Jay R. Cavanaugh. Please check the late Dr. Cavanaugh’s Wikipedia entry at http://en.wikipedia.org/wiki/Jay_Cavanaugh.

A cannabis tincture is an extraction of active cannabinoids from the cannabis plant. Ethanol alcohol or glycerin is used as a solvent to extract the cannabinoids. Properly extracted cannabinoids do not upset the stomach or taste bad. Cannabinoids are extracted, and the vast majority of terpenes and chlorophylls volatilize or are lost in the process.

A tincture delivers medicine quickly with consistent dosing. High-quality tinctures can be applied under the tongue, sublingually. The cannabis tincture is absorbed by the arterial blood supply under the tongue in a few seconds. If tincture is swallowed, absorption is via the gastrointestinal tract, which slows effects by 1 to 2 hours. The dosage is delivered via a medicine dropper, teaspoon, or spray. Dosage depends upon the potency of the tincture.

Set buds in freezer for 1 to 2 hours.

While the methods are optimized for purity and potency, ultimately these will be determined by the purity and potency of the cannabis from which the tincture is made.

A rough rule of thumb is to select indica-dominant varieties for cramping and muscle spasticity and sativa-dominant for pain relief. The reality, though, is that the variety may be unknown or not well-characterized. Trial and error is usually required to acquire the appropriate variety and the proper dose level.

There are two main solvents: methanol alcohol and glycerin. The extraction process can be cold, warm, or hot, but always below 173oF (78.3oC), the boiling point of alcohol. Dangerous hot processes are discouraged, and excessive heat degrades cannabinoids.

Common Tincture Processes Include:

Cold extraction with ethanol alcohol Warm extraction with ethanol alcohol Hot extraction with ethanol alcohol Glycerin-based extraction Sunshine extraction

Cold Extraction with Ethanol

Utensils:

- Grinder or blender

- Freezer

- Strainer

- Cheesecloth

- 1 quart (L) container with a lid that can withstand freezing

- Small dark bottles to store tincture

Ingredients:

- 1 oz (28.3 gm) cannabis

- 16 oz (1 pt [47.3 cl]) ethyl alcohol—Everclear (190-proof) or 151-proof rum

Step One: Cold-processing cannabis tinctures preserves the integrity of cannabinoids. Use high-quality flowers or kief made from small leaves and trim. Ensure that the material is dry by placing it in a defrosted, low-humidity freezer at 25oF to 14oF (-3.9oC to -10oC) for 1 to 2 hours.

Step Two: Once frozen, place dried buds in a coffee grinder and grind until thoroughly ground but not powdered. Kief and pre-pressed hashish can be ground as well. This process will open more surface area on the material, allowing cannabinoids to transfer more quickly.

Step Three: More cannabinoids are extracted when using high-percentage or high-proof ethyl alcohol (ethanol). Proof refers to half of the percentage of alcohol. For example, 90-proof is 45 percent alcohol, and 150-proof is 75 percent. The highest-proof alcohol available is Everclear at 190-proof or 95 percent ethanol alcohol. Pure 100 percent, 200-proof alcohol is not available. If unable to find Everclear, 151-proof rum is a good substitute. Other spirits that are popular for tinctures include Russian vodka in a lower proof. Some patients prefer lower proof alcohols because they burn less when sprayed under the tongue. Any distilled spirits will work.

Place the high-proof alcohol in the freezer to keep it cold.

Step Four: Mix one ounce (28.4 grams) ground flowers or kief per pint (16 ounces [47.3 cl]) of ethanol alcohol. Combine in a pre-cooled mixing container with a lid.

Step Five: Close tightly and shake vigorously for about five minutes.

Step Six: Place in freezer.

Step Seven: Remove the container and shake every two to eight hours and refreeze. Repeat the process for 48 to 72 hours. Remove the container from the freezer.

Step Eight: Use rubber gloves throughout the rest of the process. Pour the cold mixture through a kitchen strainer and then pour it through a double thickness of sterile cheesecloth. The ball of cheesecloth can be saved in the freezer for topical applications.

Step Nine: Pour the liquid that was collected through the cheesecloth, throughapapercoffeefilter—twice. Squeezethelastdropsfromthecheeseclothandcoffeefiltersintothecontainer. Makesuretoweargloves!

Step Ten: Batches of Everclear or a clear alcohol should yield a pale-green or possibly golden color. Amber-colored alcohol generally stays amber and may darken in color or change hue. Let the alcohol soak for a few months. A few drops of flavor extract can be added to the alcohol to impart a pleasant taste.

Storage: Both heat and light adversely affect cannabinoids and should be avoided or minimized. Tinctures should be stored in airtight, dark glass containers kept at room temperature or below. Avoid plastic containers if storing for more than a day. The ethanol in the tincture may solubilize some of the free vinyls in the plastic.

Today, “Green Dragon” is a popular name for many different cannabis tinctures. Green Dragon is made just like any other alcohol-based tincture using high-quality flower buds, small leaf and trim, or kief and hashish. Some Green Dragon recipes are glycerin-based tinctures.

There are several Green Dragon recipes, some of which heat the alcohol to 170oF (76.7oC). Heating alcohol tinctures is dangerous, and excessive heat degrades cannabinoids. The name “Green Dragon” may have originated among cannabis tincture pioneers before the process was perfected. A green color signifies plant material and other pollutants in the tincture.

Warm Extraction with Ethanol

Warm extraction with ethanol is just like cold extraction, except heat is added to speed the process.

Utensils:

• Grinder or blender

• Strainer

• Cheesecloth

• 1 quart (L) container with lid

• Small dark bottles to store tincture

Ingredients:

• 1 ounce (28.3 gm) cannabis

• 16 ounces (1 pt [47 cl]) ethyl alcohol—190-proof Everclear or 151-proof rum

Step One: Use small leaf trim and large leaves for this recipe. Grind the leaves to expose more surface area. Use a hand grinder for small amounts and a blender for large amounts. Do not pulverize.

Step Two: Use ethanol alcohol for a solvent, as described above in the same proportions. In this preparation the materials are kept warm (not hot). Light must be avoided.

Step Three: Place the ethanol and chopped cannabis in a large glass jar. Shake it vigorously for a few minutes and at least once a day thereafter. Place the jar in a dark-brown bag to exclude light.

Step Four: Place in a warm spot (near a window) for 30 to 60 days. The mixture will turn a very dark green. Strain as through cheesecloth and a coffee filter, as described for cold extraction.

Step Five: Once strained, the tincture is finished. The taste of this powerful cannabis tincture is usually unpleasant and may upset stomachs. Mix the tincture with coffee, cranberry juice, or sugar so it is more palatable.

Save the “shake ball” for topical applications. The shake ball should also be kept in the freezer. For topical applications, just take out the cold shake ball and apply a few drops of fresh tincture to the cloth then hold it on the affected area of skin or wound for a few minutes with gentle rubbing.

Cannabis Glycerin Tincture Utensils:

- Blender or grinder

- Crock-Pot

- Dark glass jars

- Strainer

- Cheesecloth

Ingredients: - 100 gm high-quality cannabis flower

buds - 1 qt (94.6 cl) USP food-grade glycerin

Doses: about 100

Estimated Time: 6 hours—5 weeks

Make a glycerin-based tincture with gland-rich cannabis flowers, about 2 cups (47.3 cl). If possible, make your batches of tincture variety-specific.

Soak cannabis in cold water for 15 to 20 minutes to rinse away much chlorophyll; let drain. Put enough trim in your jar to fill it to about three-fourths full. Add vegetable-grade glycerin to within a few inches of the top. Cap and store in a cool, dark place, taking it out at least once daily to roll and shake for 5 to 10 minutes. This process should be done for at least 60 days, and can be left even longer for stronger tincture. I then set the jar into a pot of hot water under very low heat for 10 to 15 minutes to help separate more of the trichomes (never getting over 185oF [85oC]), which makes it easier to strain. Then strain and or press to separate trim from glycerin. Some people use coffee filters for final straining; I use silkscreen.

Keep refrigerated.

The recipe below was extrapolated from “Glycerin-based Tincture” by Leanne Barron. The original work appears on the Marijuana Growing forum: [enlace web]

Glycerin is vegetable-based and has little impact on blood sugar and insulin levels. Even though it is sweet, it has less than 5 calories per gram and contains no alcohol. Alcohol-based tinctures have a longer life than glycerin-based tinctures.

Extend the life of glycerin-based tinctures by keeping them in the refrigerator.

Step One: Place cannabis in a clean coffee grinder or blender, and grind.

Step Two: Pour glycerin and cannabis into a Crock-Pot. Carefully brush residual cannabis out of the grinder. Stir. Set the Crock-Pot on its lowest possible setting. Some Crock-Pots’ low settings are too high and cannot be used. If there is a “Keep Warm” setting, that is the best option.

Step Three: Do not let the mixture boil! Keep the temperature below boiling, and let simmer for up to 24 hours.

Step Four: Turn off the Crock-Pot and let the mixture cool enough to handle with gloves. Strain the mixture through cheesecloth. It takes longer for glycerin to pass through the process than alcohol. Be patient. Do not use a paper coffee filter that will clog.

Step Five: Tincture is ready to be bottled in dark glass containers.

If using a clear container to contain the tincture, store it in a dark place and minimize contact with sunlight and artificial light.

Lotions and Salves

Cannabis Lotions

The basic recipe for any lotion is incredibly simple: Oil and water are combined and bonded together with an emulsifier. Once the emulsifier is blended in, fragrance and essential oil are added.

There are two types of emulsifiers. Oil-in-water (o/w) emulsifiers keep oil drops packed in water. The other kind, water-in-oil (w/o) emulsifiers keep water drops packed in oil. Use w/o emulsifiers for sun-protection creams. Use o/w emulsifiers for moisturizing body lotions.

Make cannabis body lotion with skin-nourishing cannabis oil and pure water. Add vitamin E oil to the mix as a short-term preservative, and keep natural products in the refrigerator. See http://www.makingcosmetics.com for more information.

Step One: Combine a half cup (11.8 cl) of cannabis oil and 2 tablespoons (28.3 gm) of beeswax, an emulsifier, in a saucepan on the stove. Melt the beeswax and mix with the cannabis oil.

Step Two: Slowly pour distilled water into the warm mixture and stir rapidly with a whisk until well blended. Use a stick blender to add air to the mix and make it fluffy. Be careful when submerging the mixer and keep it on a low speed to avoid splashing.

Step Three: Let lotion cool, during which time it will become thicker, and spoon it into a clean jar with a pump applicator.

Cannabis Salves

Cannabis salves and balms are easy to make topical medicinal ointments. First, the beneficial properties of cannabis are extracted in oil or glycerin, then beeswax is added to harden the oil. The base for all recipes is either hemp oil or a cannabis tincture mixed with oil. Cannabis salves, ointments, and balms are applied to the skin, and cannabinoids do not transfer to the bloodstream, so the quality and concentration of specific cannabinoids are less important. Low-cannabinoid, clean leaves are ideal for making these topical medicines.

Grape-seed oil is a particular favorite ingredient because it is easily absorbed by the skin. Coconut oil and glycerin are also popular. Olive oil is avoided because it is much slower to be absorbed.

Many other essential oils can be incorporated into the mix. Some mixes, such as Tiger Balm, can be used as a base to which extracted cannabis is added. The ingredients are usually added near the end of the process, once the mix has cooled. Active ingredients are added and emulsify in the mix. Stirring evenly is important to get an even mix. Popular healing salves today often include menthol crystals, ichthammol, phenyl alcohol, or Arnica montana, echinacea, and calendula. There are numerous recipes on the Internet.

Do not use fresh cannabis unless you add a preservative such as Germaben. Balms and lotions made with fresh cannabis should be stored in the refrigerator to prolong life.

Tiger Balm

| RECETA DE BÁLSAMO DE TIGRE | ||

|---|---|---|

| Ingredient | Red | White |

| Ingredient | 10% | 8% |

| camphor | 10% | 11% |

| aceite desmentalizado | 6% | 16% |

| cajuput oil | 7% | 13% |

| clove bud oil | 5% | 1.5% |

| cassia oil | 5% | 0% |

| The mix is held together with a paraffin base and petroleum jelly. | ||

Cannabis Salve: Step-by-Step

Ingredients:

- 1 pt (47.3 cl) of grape-seed oil

- 1.5 oz (42.5 gm) beeswax

- 1 oz (28.3 gm) cannabis leaf

Step One: Add cannabis to a glass, enamel, or stainless steel Crock-Pot. Add one pint (47.3 cl) grape-seed oil.

Step Three: Heat the mix on low heat for 2 to 3 hours. Do not let boil. I prefer to use a Crock-Pot because the heat is easy to control and they are lined with a ceramic bowl.

Step Four: After heating, let the oil mix cool before pouring through a cheesecloth-lined strainer. Once the oil has filtered through and cooled enough to handle, pick up the cheesecloth containing cannabis and squeeze out residual oil.

Step Five: Add beeswax to the warm oil mix and heat on low until the wax melts. To test if your salve is hard enough, put some on a spoon and set it in a cool place for a few minutes. If your salve is too soft, add more beeswax.

Step Six: If you are using essential oils or vitamin E, you can blend them in now. Finally, pour your salve into containers and label.

Glycerin-Based Salve

We have two recipes for glycerin-based salves. The first recipe uses an emulsifying wax and liquid vegetable glycerin along with a couple of preservatives. The second uses beeswax, coconut oil, aloe vera oil, and hemp oil as a base. Note: The coconut oil can consist of cannabis coconut oil.

Ingredients:

- 24 oz (71 cl) distilled water

- 4.0 oz (11.8 cl) strong cannabis oil or fat

- 1.2 oz (3.5 cl) emulsifying wax

- 1.2 oz (3.5 cl) cosmetic grade (benign) stearic acid

- 1 oz (3 cl) liquid vegetable glycerin

- 0.3 oz (0.9 cl) Germaben (a natural preservative that prevents spoilage)

- 0.3 oz (0.9 cl) essential oil of your preference

Step One: Heat all ingredients in a double boiler until melted, and then whisk until creamy.

Step Two: Add the last two ingredients and whisk thoroughly. Add menthol crystals instead of essential oils to make a cooling menthol sunburn salve.

Step Three: While warm, pour into bottles. Makes approximately 32 ounces (94.6 cl).

Alcohol-Based Salve

Utensils:

Crock-Pot

Ingredients:

- 0.5 lb (226.8 gm) beeswax

- 32 oz (94.6 cl) unrefined coconut oil

- 8 oz (23.7 cl) aloe vera oil

- 32 oz (94.6 cl) hemp oil or cannabis tincture

- 0.5 to 1 tsp (0.25–0.5 cl) essential vanilla oil

- 0.5 to 1 tsp (0.25–0.5 cl) vitamin D oil (optional)

Step One: Melt 2 cups of cannabis coconut oil in a Crock-Pot. Set the Crock-Pot to low and simmer. Do not bring to a boil.

Step Two: Melt and measure 1 ounce (28 gm [1/8 cup]) of beeswax into the Crock-Pot. Add 5 ounces (14.8 cl) cannabis (unrefined) coconut oil. Stir until clear. Add aloe vera oil and stir until clear.

Step Three: Turn off the Crock-Pot and put the liner with contents into the refrigerator until a skin develops on the top.

Step Four: Remove mixture from the refrigerator and stir in hemp oil, vanilla oil, and 1 tablespoon vitamin E oil and any drops of fragrance and other oils now. Mix together in Crock-Pot. Stir or whisk until well mixed. An immersion blender can also be used to “fluff” salve, adding air and volume.

Step Five: Scoop salve into small containers with lids for storage, and use.

Budder, also known as wax, is an extremely potent cannabis concentrate made from the resin glands of the cannabis plant. (MF)

Budder (wax) (MF)

Glass or shatter, another type of cannabis concentrate, will shatter into numerous pieces if it’s dropped on a hard surface. (MF)

Butane hash oil (BHO) is chemically extracted from dry cannabis. (MF)

Budder (wax) close-up (MF)

A close-up view of this shatter shows the subtle differences in the extraction. (MF)