Light is essentialfor cannabis to grow strong, healthy medicine. All plants grow and evolve under Mother Nature’s sunlight and care. Plants are accustomed to natural sunlight and have adapted to her spectrum, intensity, and photoperiod. Light is comprised of separate wavelengths or bands of colors. Each color in the spectrum used by plants sends them separate signals, promoting a different type of growth.

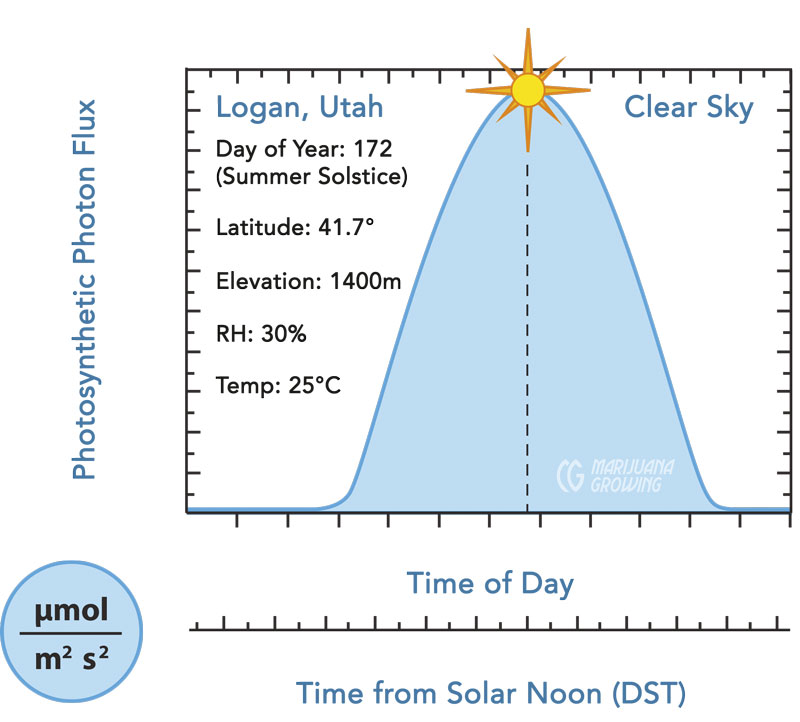

Sunlight contains 4 percent ultraviolet radiation, 52 percent infrared (heat) radiation, and 44 percent visible light. Midday during the bright summer growing season, light intensity can top 8640 foot-candles (93,000 lux), but cannabis plants use about half the energy found in natural sunlight.

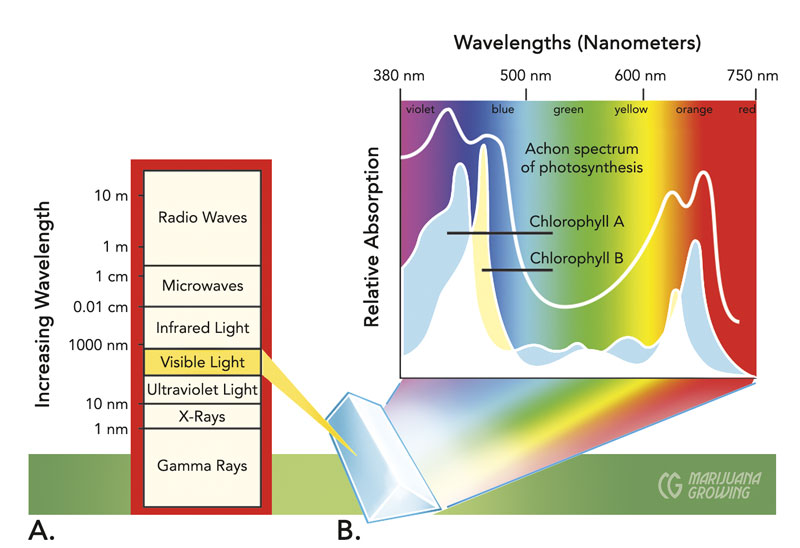

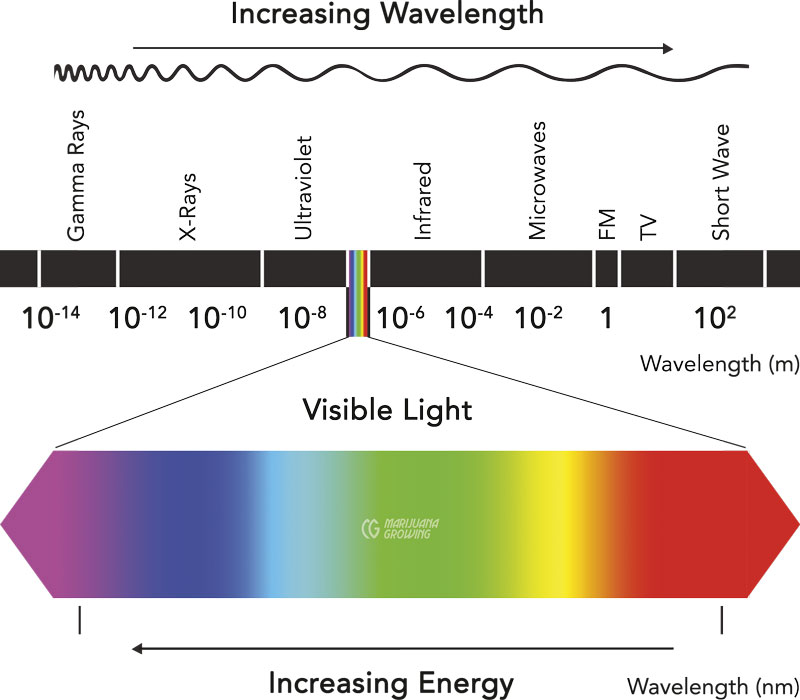

Sunlight energy arrives from the heavens as electromagnetic radiation. It is both wave and particle in nature. The smallest divisible particles of light are called photons. The brightness of light is equivalent to the number of photons absorbed per unit of time. Each photon contains a fixed amount of energy. The energy in each photon dictates how much it will vibrate. The wavelength is the distance moved by a photon during one vibration. Wavelengths are measured in nanometers.*

*One nanometer (nm) = one billionth (109) of a meter. Light is measured in wavelengths; the wavelengths are measured in nanometers.

Electromagnetic radiation spans a broad range of wavelengths. Gamma rays with a wavelength of 105 nm are at the far blue end of the spectrum and radio waves with a wavelength of 1012 nm are at the far-red end. Red light has a longer wavelength. The photons vibrate slower and contain less energy. Photons in the far blue ultraviolet (UV) visible spectrum have shorter wavelengths and contain more energy. The human eye sees only “visible light” (wavelengths between 380 and 750 nm) a small part of the entire spectrum. Visible light wavelengths (light spectrum) appear to people as all the colors of the rainbow. Visible light is measured in foot-candles (fc) and lux (lx). Lumens are the measure of visible light emitted by a light source.

Lumens measure “luminous flux,” the total number of packets (quanta) of light produced by a light source. Luminous flux is the quantity of light emitted.

Use the lux measurement to know how many lumens to give the entire area for complete illumination.

Unlike lumens, lux measures the area over which the light (luminous flux) spreads. For example, if 1000 lumens were concentrated in one square meter, the illuminated square meter would have 1000 lux. If the same 1000 lumens spread over 10 square meters, a measurement of 100 lux is registered on the 4 square meters.

Plants “see” other parts of the light spectrum than humans see. They respond to wavelengths similar to those that humans need to see, but they use different portions of the spectrum. Peak needs to occur in the blue portion (430 nm) and red portion (662 nm) of the spectrum, where chlorophyll* absorption is at the highest levels. Light used by plants is measured in PAR (photosynthetically active radiation), PPF (photosynthetic photon flux) (μmol/s).

*Chlorophyll is the most important light-absorbing pigment in cannabis, but it does not absorb green light. Green light is reflected, which is why we see the color green. Other pigments include carotenoids (a group of yellow, red, and orange pigments) that absorb light energy. Other pigments (e.g. zeaxanthin [red] and phycoerythrin [red]) absorb different wavelengths. Each color of light activates different plant functions. For example, positive tropism*, the plant’s ability to orient leaves toward light, is controlled by spectrum.

*Phototropism is the movement of a plant part (foliage) toward a source of illumination. Positive tropism means the foliage moves toward the light source. Negative tropism means the plant part moves away from the light. Positive tropism is greatest in the blue end of the spectrum, at about 450 nanometers. At this optimum level, plants lean toward the light, spreading their leaves out horizontally to absorb the maximum amount of illumination possible.

PAR watts are a measure of light energy (radiant flux) used by plants to produce food and grow. PAR watts are the measure of the actual amount of specific photons a plant needs to grow. Light energy is radiated and assimilated in photons. Photo synthesis is necessary for plants to grow, and is activated by the assimilation of photons.

Ultraviolet (UVA, UVB, UVC) Light

UVA is the most common UV light. It has little energy and is least harmful of all UV light. Used in glow-in-the-dark black lights, UVA light is also used in phototherapy and in tanning booths.

Black-light fluorescent lamps emit ultraviolet rays through a dark filter and glass bulb, but they are not appropriate to grow cannabis. According to some sources, ultraviolet light is supposed to promote more resin formation on flower buds. However, all known experiments that add artificial UV light in a controlled environment have proven that it does not make any difference.

UVB is a very damaging form of UV light. It packs enough energy to destroy live tissues but not enough energy to be absorbed completely into the atmosphere. Destructive UVB can cause skin cancer. Be careful when outdoors, especially in areas with damaged ozone layers in the atmosphere that let more UVB light pass through. These are high-risk areas for skin cancer.

UVC light is absorbed almost completely, and within a kilometer of the atmosphere. The UVC photons crash into oxygen atoms, and the result is ozone. In nature, UVC is transformed into ozone and later oxygen so quickly that it is difficult to capture. UVC light works well as a germicidal water purifier and bacteria-killer in food. It also works well to kill bacteria, mold, and pests on plant leaf surfaces.

UVC light (100–280 nm) carries too much electromagnetic radiation, or energy (the hyper atoms are moving too fast), for plants to process; the energy is sufficient to force electrons away from atoms and rupture fragile chemical bonds.

UVC light is used in short, limited, regular applications to kill mold spores in growing and harvested cannabis. UV radiation is absorbed by oxygen in the forms O2 and O3 (ozone). The ozone layer of our atmosphere protects life on the planet from high levels of UV radiation.

UVA (315–380 nm) and UVB (380–315 nm) light help new branch growth and have a similar effect as blue light. Ultraviolet (UVA and UVB) light emitted by natural sunlight and plasma lamps has been proven to increase overall vegetative growth in cannabis by up to 30 percent.

In experiments, vegetative plants grown under plasma lamps that emit UVA and UVB light grew up to 30 percent more dry weight, and branching was much more profuse. Cells were stronger and the outer layer of cells was tougher, which discourages attacks from diseases and pests.

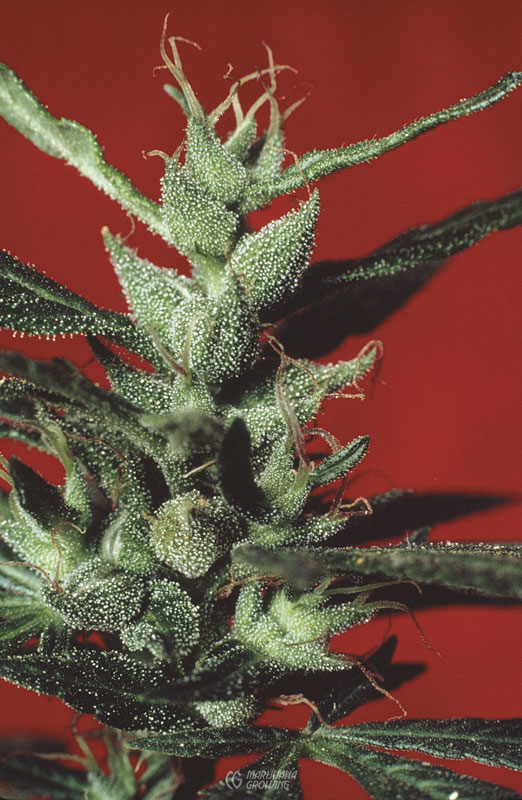

I have personally seen plants grown at 1000-foot (300 m) and 4600-foot (1400 m) elevation. The plants at 1000 feet (300 m) produced more and bigger flower buds. The plants at 4600 feet (1400 m) were smaller, with thicker, stronger stems and smaller buds heavy with resin. Afterward, both crops were compared. The plants grown at high elevation had more resin, but it is unclear if that was because of more UVB light. There are many different explanations for heavier resin production, including cold weather and wind.

Random photons of infrared light (750–1000 nm) on the other end of the spectrum do not contain enough energy to promote plant growth. Infrared radiation is not absorbed by plant cells, because it lacks enough energy to excite electrons found in molecules and is therefore converted to heat.

Gardeners who use infrared heaters do not have to worry about light affecting plant growth. Infrared radiation is absorbed by water and by carbon dioxide in the atmosphere.

Blue photons carry more energy and are worth more PAR watts than lower-energy red photons. It takes from 8 to 10 photons to bind 1 CO2 molecule.

PAR watts in photons-per-second became the standard to measure horticultural lamp spectrum output. This measurement is called photosynthetic photon flux (PPF), and is expressed in micromoles-per-second (μmol/s). Today PPF is the accepted lighting and greenhouse industry standard.

Outdoors, plants receive natural sunlight—100 percent PAR/PPF. Greenhouse and shade cloth coverings limit the amount of PPF. Look for the “light transmission” factor in greenhouse and shade cloth coverings to figure the amount of PAR/PPF light available to plants.

Most artificial lights deliver only a part of the necessary light spectrum that cannabis needs to grow. A higher PAR/ PPF rating guarantees that more photons will be available for healthy plant growth. Under artificial lights indoors, medicinal cannabis must receive enough intense PAR/PPF light to grow well. Gardeners report that medical cannabis grown under intense lamps with high PAR/PPF ratings is healthier and stronger, with fewer disease, pest, or cultural problems.

Light Intensity

Sunlight on a hot summer day when the sun is at the highest angle in the sky produces light levels of more than 93,000 lux—all the PAR light you could possibly need!

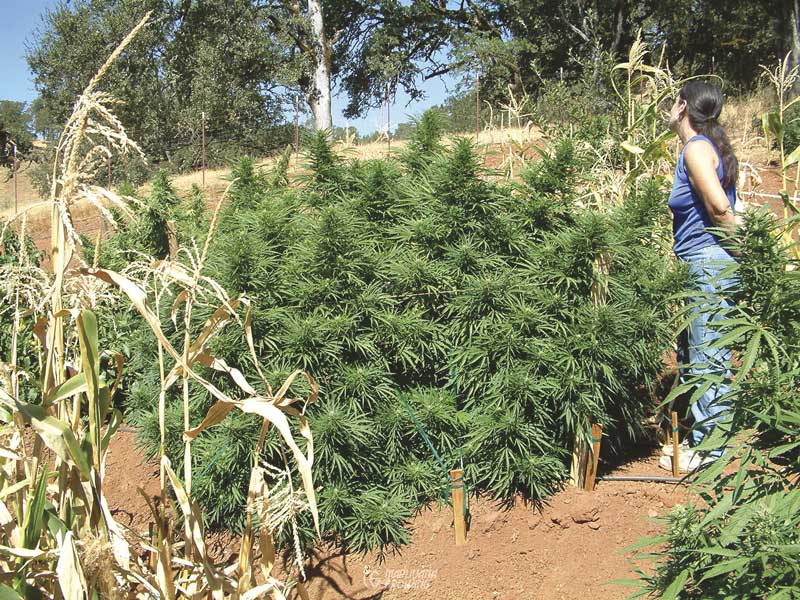

Outdoors, little can be done to change the PAR rating except to plant the garden in a sunny location, and to shade the plants as needed. Greenhouses can be illuminated with HID light, but outdoors we are compelled to work with Mother Nature during cloud-covered days. We can use greenhouse coverings and shade cloth to cool plants and decrease intense light.

| ILLUMINANCE (LUX) | EXAMPLE |

| 93,000 | Brightest sunlight at midday |

| 20,000 | Shade illuminated by a clear blue sky at midday |

| 10,000–25,000 | Overcast day at midday |

| <200 | Super dark storm clouds at midday |

| 400 | Sunrise and sunset on a clear day |

| 40 | Overcast sky at sunset or sunrise |

Indoors, artificial lightbulbs and tubes must supply intense light for medicinal cannabis to grow well. The lamp must have the proper spectrum and have a high PAR rating.

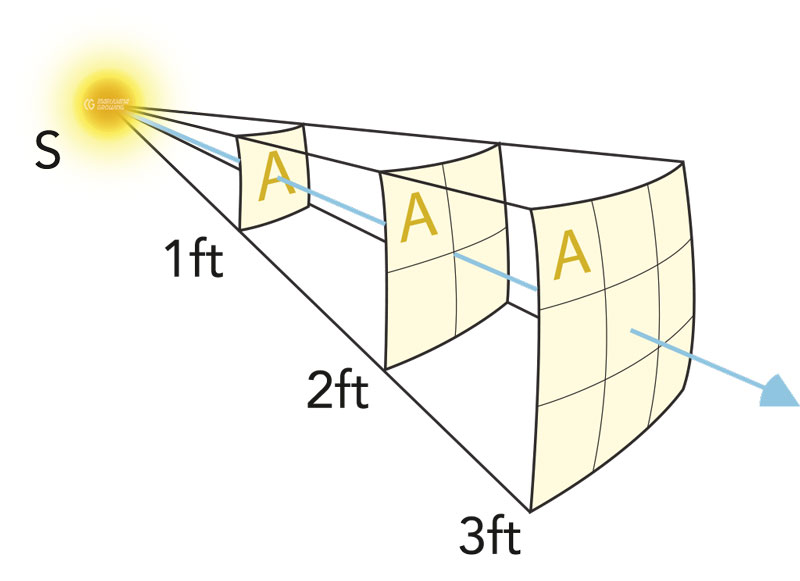

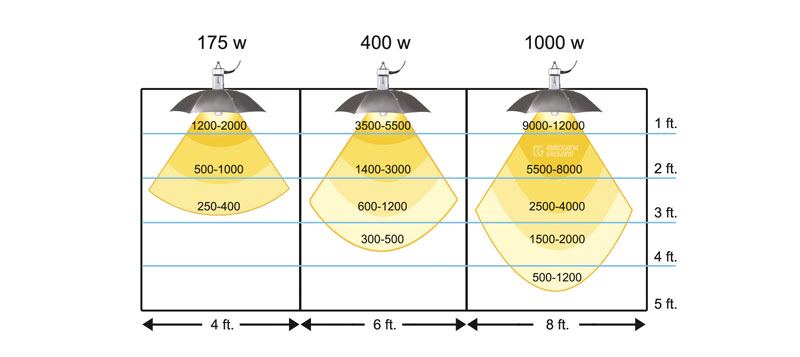

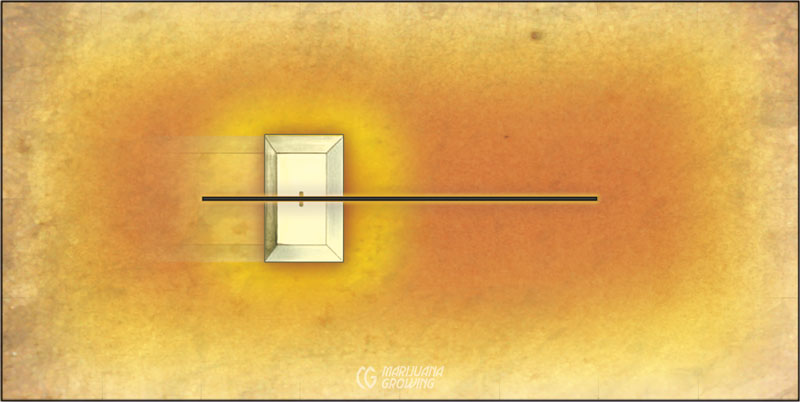

Indoors, generating intense light is expensive and requires knowledge to employ a bulb with the proper spectrum. Intensity is the magnitude of light energy per unit of area. It is greatest near the bulb and diminishes rapidly as it moves away from the source. High-wattage HID (high-intensity discharge) bulbs supply the most intense light efficiently, followed by T5 and T8 fluorescent, and CFL and plasma lamps. But remember that T5 and T8 bulbs can be placed four times closer to plants, which makes them much more efficient than HID bulbs, according to the Inverse Square Law (see below).

For example, plants that are 2 feet (61 cm) from a lamp receive one-quarter the amount of light received by plants 1 foot away (30.5 cm). An HID that emits 100,000 lumens produces a paltry 25,000 lumens at 2 feet (61 cm) away. A 1000-watt HID that emits 100,000 initial lumens yields 11,111 lumens at 3 feet (91.4 cm) away. Couple this meager sum with a poorly designed reflective hood that has lost its shine, and the garden suffers.

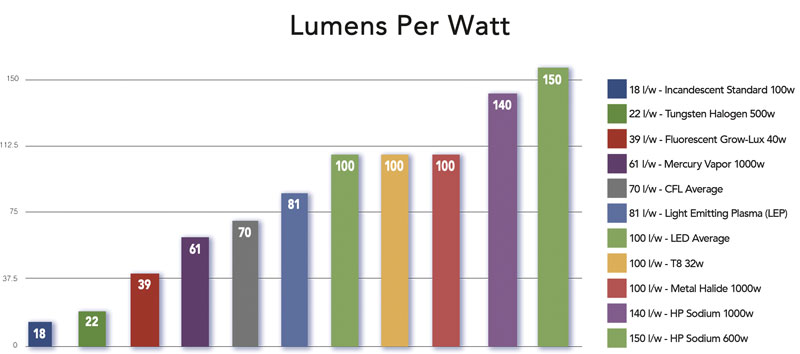

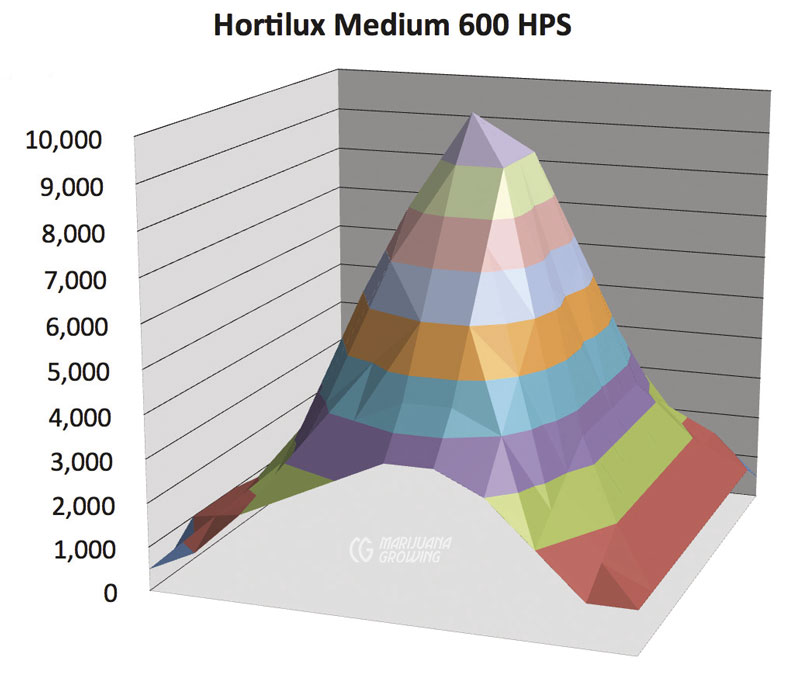

For plant growth, the brilliance of a lamp has a limited effect when it does not produce the proper spectrum. For example, the efficient 600-watt HP sodium lamps have the highest lumens per watt (lm/W) conversion, but a color rendering index (CRI) of 24 and spectrum of 2000 K to 3000 K. Even though these lamps produce more light per watt, plants can use only parts of it!

| LAMP | WATTS | INITIAL LUMENS | MEAN LUMENS |

| MH | 1000 | 100,000 | 80,000 |

| SMH | 1000 | 115,000 | 92,000 |

| HPS | 1000 | 140,000 | 112,000 |

| HPS | 600 | 90,000 | 72,000 |

Lumens emitted are only part of the equation. Lumens received by the plant are much more important. Lumens received are measured in watts per square foot or in foot-candles (fc). One foot-candle equals the amount of light that falls on 1 square foot of surface located 1 foot away from 1 candle.

Measuring Light

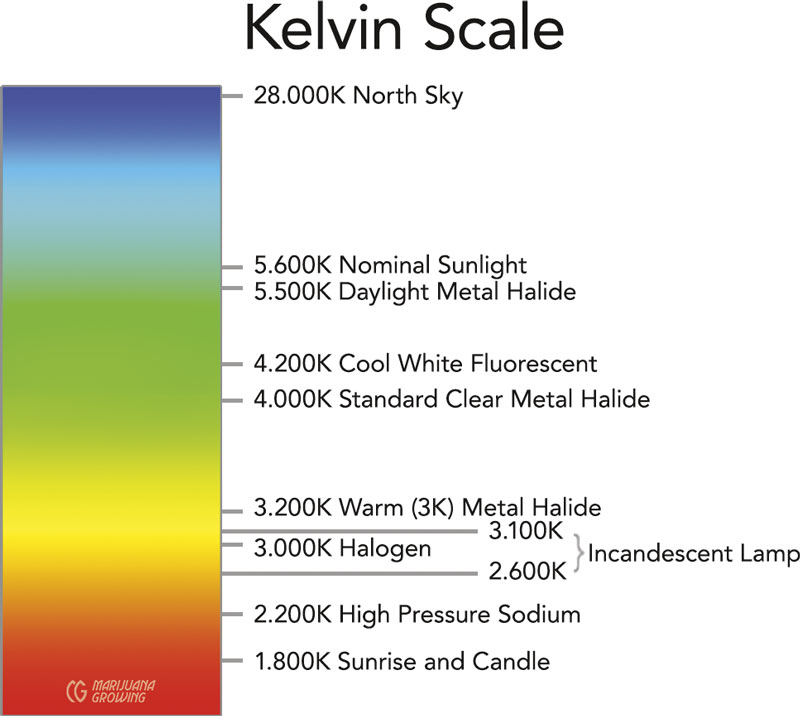

As explained earlier in this chapter, plants use the PAR portion of the light spectrum to grow. Artificial lights that produce the highest PAR rating with a high-intensity are the logical choice to grow medicinal cannabis. To find out which lightbulbs supply the most usable light for photosynthesis, reference their color rendering index (CRI) and the Kelvin (K) temperature ratings. The CRI indicates how close the lamp’s spectrum is to natural sunlight. The color temperature (spectrum) of the bulb is expressed in kelvins. Kelvin is an absolute measurement of temperature that indicates the exact color spectrum a bulb emits. Lightbulbs with a Kelvin temperature from 3000 to 6500 will grow medicinal cannabis. These two figures, coupled with lamp intensity expressed in lumens, can approximate a PAR rating for lamps that do not have one.

The color rendering index (CRI) is a scale used to measure the ability of a light source to reproduce the colors of various objects faithfully in comparison to an ideal or natural light source, which means how true to life these colors appear in the visible spectrum when they are being illuminated with anything other than natural light.

The color corrected temperature (CCT) of a bulb is the peak Kelvin temperature at which the colors in a bulb are stable. We can classify bulbs by their CCT rating, which tells us the overall color of the light emitted. It does not tell us the spectrum (concentration of the combination of colors emitted).

Light is commonly measured in foot-candles or lux, two scales that measure light visible to humans, but do not measure photosynthetic response to light in PAR or PPF. Lumens are a measurement of light emitted from the sun or artificial light. Light meters that measure in PAR or PPF are very expensive and seldom used by medical cannabis gardeners. Foot-candle and lux meters can also be used to achieve an approximate measure of light available to plants. The foot-candle and lux readings are still valuable, because they record the amount of intense (PAR/PPF) light spread over a specific area.

Using an inexpensive light meter to calculate lumens, foot-candles, or lux is a way to estimate the amount of light plants receive. But it does not measure how much light is available to plants.

The Inverse Square Law

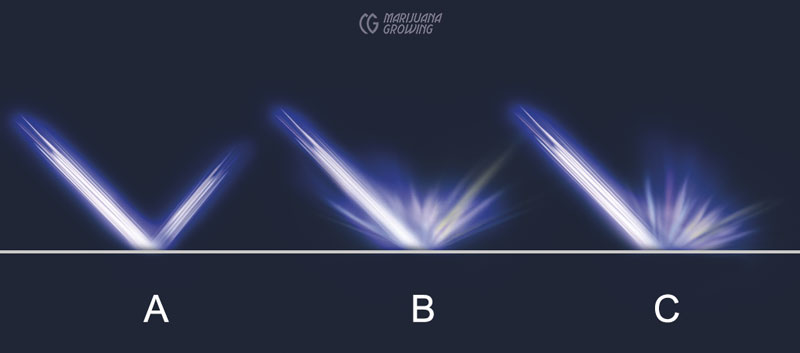

The relationship between light emitted from a point source (bulb) and distance is defined by the inverse square law. This law affirms that the intensity of light changes in inverse proportion to the square of the distance. Light diminishes rapidly.

I = L/D2

Intensity = light output/distance2

For example:

Distance Intensity = light output/distance2

| Feet | Centimeters | Lumens | Lumens/Distance2 |

| 1 | 30 | 100000 | 100000/1 |

| 2 | 60 | 25000 | 100000/2 |

| 3 | 90 | 11111 | 100000/3 |

| 4 | 120 | 6250 | 100000/4 |

Once you know the PAR rating of a lamp, using a foot-candle or lux meter will measure light intensity at the foliage. The foot-candle or lux light meter measures the overall intensity of visible light over a garden. Use the most efficient lamp with the highest PAR or PPF (μmol/s) rating for the application: seedling/clone, vegetative, and flowering. Outdoors and in greenhouses, plants that do not receive enough intense light grow slowly. Lack of light during flowering keeps flower buds from filling out and putting on weight.

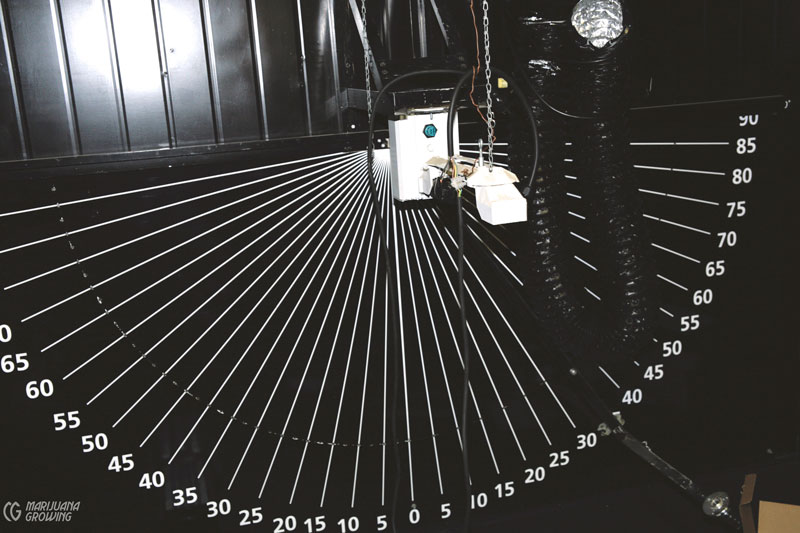

Light meter readings vary a lot as a result of orientation. To get the most accurate readings, orient the meter at a 90-degree angle from the garden canopy when taking measurements. Avoid pointing the light sensor directly at a bulb unless measuring directly below bulb.

*Light can be measured in many different scales: foot-candles, lumens, lumens/cm², lumens/ft², lumens/m², lux, phot, nox, candlepower, meter candle, nit, stilb, lambert, foot-lambert, millilambert, candela/m², candela/cm², candela/ft², and candela/in², watts, microeinsteins, millimoles, joules, photons, radiant flux, luminous flux, PAR, PPF, etc. To figure out conversions to different scales for measuring light, OnlineConversion.com will do the math for you: www.onlineconversion.com/light.htm.

According to lighting expert Theo Tekstra from Gavita-Holland, “Micromoles is the way to express photons.” Micromoles measure the number of photons per second, or irradiation of photons per second per meter. Micromole = μMol

To get an idea of how well a medical cannabis plant will grow under a specific greenhouse covering or lightbulb, three things must be known: (1) PAR, (2) intensity, and (3) hours of darkness.

Photoperiod

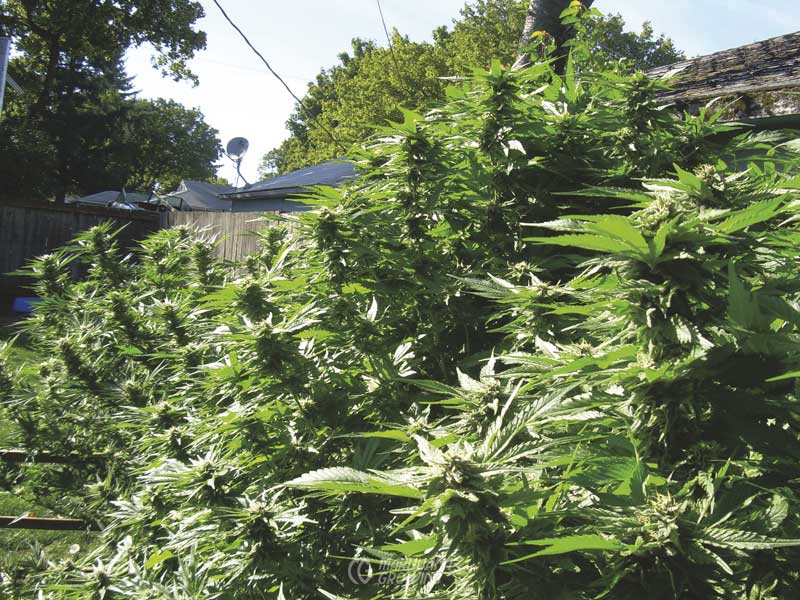

The photoperiod is the relationship between the duration of the light period and dark period. In nature, cannabis normally flowers in the fall, when nights grow long and days short.

In general, cannabis is a short-day plant that will flower when it receives short 12-hour days and 12-hour nights. (C. ruderalis, however, is a long-day plant.) Most varieties of cannabis will stay in the vegetative growth stage as long as an 18- to 24-hour light and a 6- to 0hour dark photoperiod are maintained. However, there are exceptions. Eighteen hours of light per day will give cannabis all the light it needs to sustain vegetative growth. Cannabis can efficiently process 16 to 18 hours of light per day, after which it reaches a point of diminishing returns and the electricity is wasted. (See chapter 25, Breeding.)

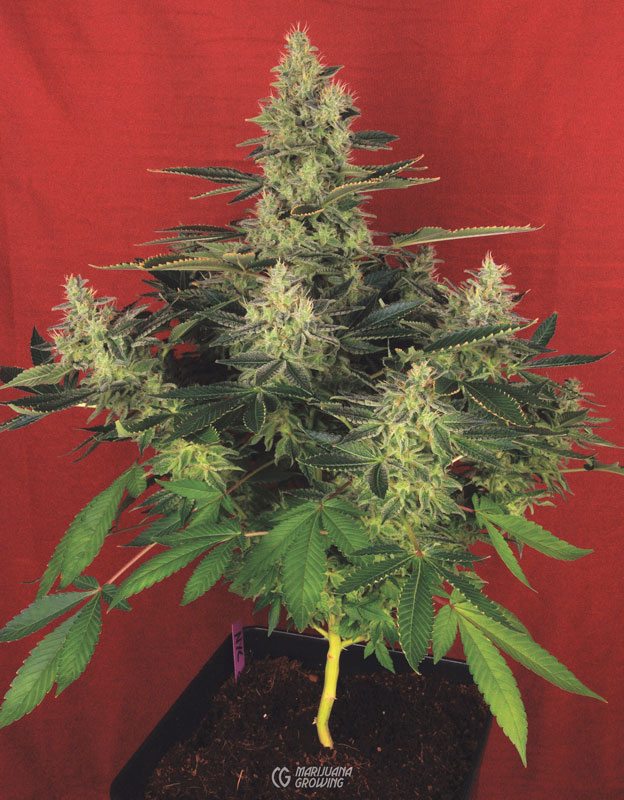

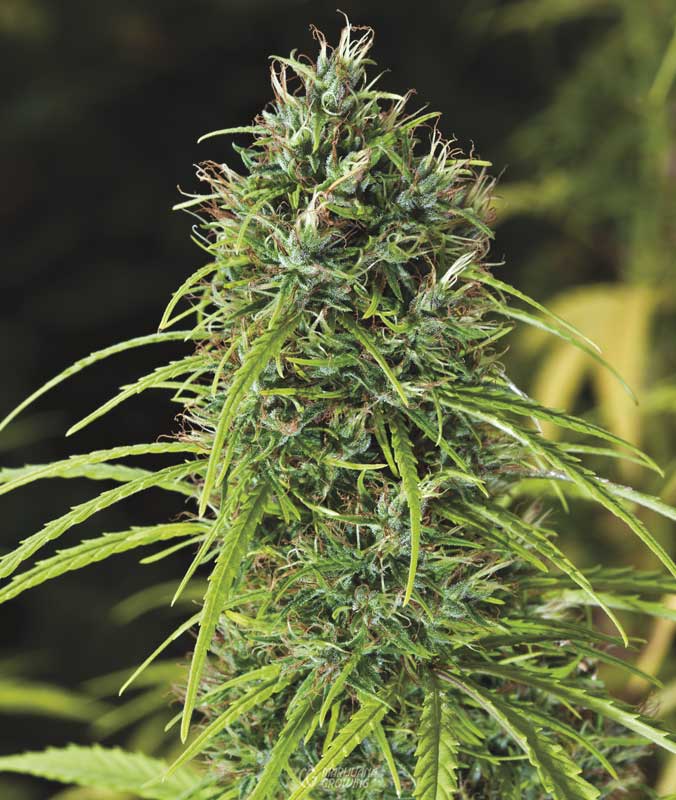

Flowering is most efficiently induced in most varieties of cannabis with 12 hours of uninterrupted darkness in a 24-hour photoperiod. When plants are at least 2 months old—after they have developed male and female sexual characteristics— altering the photoperiod to an even 12 hours, day and night, will induce visible signs of flowering in 1 to 3 weeks. Older plants tend to show signs of flowering sooner. Varieties originating in the tropics generally mature later, and more hours of darkness shorten flowering time. The 12-hour photoperiod represents the classic equinox and is the standard daylight-to-dark relationship for flowering in cannabis.

Some gardeners experiment with gradually decreasing daylight hours while increasing hours of darkness. They do this to simulate the natural photoperiod outdoors. This practice prolongs flowering and does not increase yields. Genetically unstable varieties could express intersex (hermaphroditic) tendencies if the photoperiod bounces up and down several times. If you plan to give plants a photoperiod of 13/11 day/night, stick to it. Do not decide you want to change the photoperiod to 15/9. Such variation will stress plants and could cause intersexuality.

Tropical gardeners that get 12 to 13 hours of light and at least 11 to 12 hours of darkness year round can grow plants with artificial light the first month or two of life and set them outdoors to induce flowering with the long nights. Such gardens can flower for two or three months, harvested and replanted year round. Other gardens in latitudes further north with good weather could grow autoflowering feminized plants during the long summer days to avoid having to cover greenhouses to induce flowering.

The photoperiod signals plants to start flowering; it can also signal them to remain in (or revert to) vegetative growth. Cannabis must have 12 hours of uninterrupted total darkness to flower properly. Dim light during the dark period in the pre-flowering and flowering stages prevents cannabis from blooming.

When the 12-hour dark period is interrupted by light, plants get confused. The light signals plants, “It’s daytime; start vegetative growth.” Given this signal of light, plants start vegetative growth, and flowering is retarded or stopped.

Cannabis will not stop flowering if the lights are turned on for a few minutes once or twice during the 2-month-long flowering cycle. If a light is turned on for 5 to 30 minutes—long enough to disrupt the dark period—on 3 to 5 consecutive nights, plants will start to revert to vegetative growth.

Less than one half of one foot-candle of light will prevent cannabis from flowering. That is a little more light than is reflected by a full moon on a clear night. Well-bred indica-dominant plants will revert within three days. Sativa-dominant plants take four to five days to revert to vegetative growth. Once they start to revegetate, it can take from four to six additional weeks to induce flowering again!

There are other photoperiods possible. For example, you can give plants 12 hours of HID light and the remaining 6 hours of incandescent light for a total of 18 hours to save on electric bills. But other light regimens that do not allow for 11 to 12 hours of darkness in 24 hours are going against Mother Nature. If sales people promise higher yields, watch out for disproportionate use of electricity. There are also some screwy photoperiod regimens that should not be followed!.

A relationship exists between photoperiod response and genetics. Little scientific information is available about which specific varieties of cannabis are affected by photoperiod.

Sativa-dominant varieties that originated in the tropics respond to long days better than indica-dominant varieties, even though both are short-day plants. On the equator, days and nights are almost the same length year round. Plants tend to bloom when they are chronologically ready, after completing the vegetative growth stage. For example, the pure sativa variety ‘Haze’ flowers slowly for 3 months or longer, even when given a 12- hour photoperiod.

Give ‘Haze’ varieties more darkness and less light hours to speed harvest time and make flower buds fill in faster. Start with the 12/12 photoperiod and change to a 14 dark/10 light photoperiod after the first month. Play around a little with the photoperiod on pure sativas to dial it in for specific varieties.

You can start ‘Haze’ on a 12/12 day/ night schedule, but it still must go through the seedling and vegetative stages before spending 3 months or longer flowering. Plants grow more slowly in 12-hour days than when given 18 hours of light, and inducing flowering takes longer.

Indica-dominant varieties that originated in northern latitudes tend to flower sooner and respond more quickly to a 12- hour photoperiod. Many indica varieties will flower under a 14/10 or 13/11 day/ night photoperiod. Again, the hours of light necessary to induce flowering in an indica-dominant plant is contingent upon the genetics in the variety. More hours of light during flowering can cause some varieties to produce bigger plants, but flowering time is usually longer and some gardeners have reported looser, leafier flower buds as a result.

Some gardeners have achieved higher yields by inducing flowering via the 12- hour photoperiod, then changing to 13 to 14 hours of light after 2 to 4 weeks. This practice works best with early-flowering indica-dominant varieties, but flowering might be prolonged. I spoke with gardeners who increase light by 1 hour 2 to 3 weeks after flowering is induced. They say the yield increases about 10 percent. Flowering takes about a week longer, however, and different varieties respond differently.

Horticulturists in the “green industry” state that once the bud is competent (after the juvenile stage) and will respond to flowering signals, it is determined (changed to a floral bud), which means it is going to flower. High stress by light levels, photoperiod, temperature, etc., can delay or cause abortion and maybe a shift back to adult vegetative growth. However, it is common practice that photo controls are dropped about a third to half of the time to harvest in most green industry production. They typically add or subtract an hour or two of light a day, just like cannabis growers. Nevertheless, this stress (longer days) could also be the trigger to shock plants out of the flowering stage.

Ruderalis-dominant varieties are autoflowering. Cannabis sativa and C. indica varieties are crossed with C. ruderalis. Some of the offspring contain the autoflowering genes. Autoflowering plants are often feminized. The seeds are planted indoors and grown indoors, outdoors, or in greenhouses. These varieties flower under 24 hours of light after about three weeks of growth. C. ruderalis crosses will flower under any light regimen. However, when growing indoors many gardeners report that a light regimen of 20 hours light and 4 hours dark will spur the most growth.

Some gardeners give plants 36 hours of total darkness just before inducing flowering with the 12/12 photoperiod. This heavy dose of darkness sends plants an unmistakable signal that causes a hormonal change to stimulate flowering. Gardeners using this technique report that plants normally show signs of flowering, such as stigma formation, sooner than normal.

Indoor and Greenhouse Garden Lamps

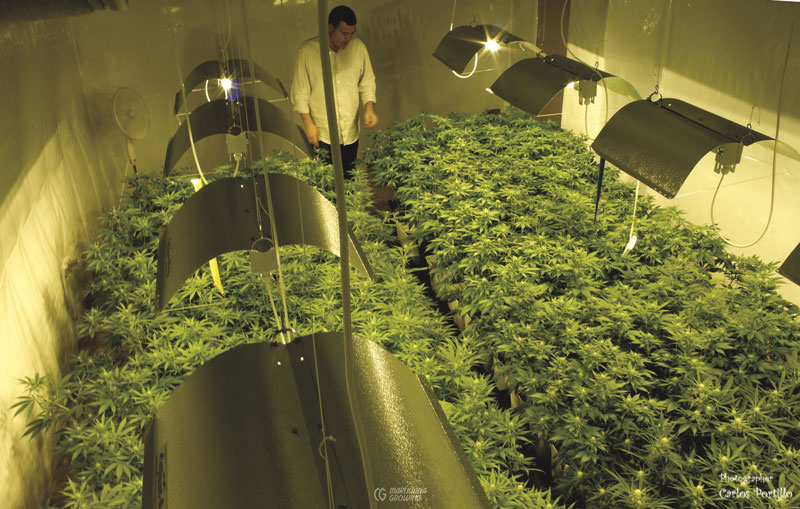

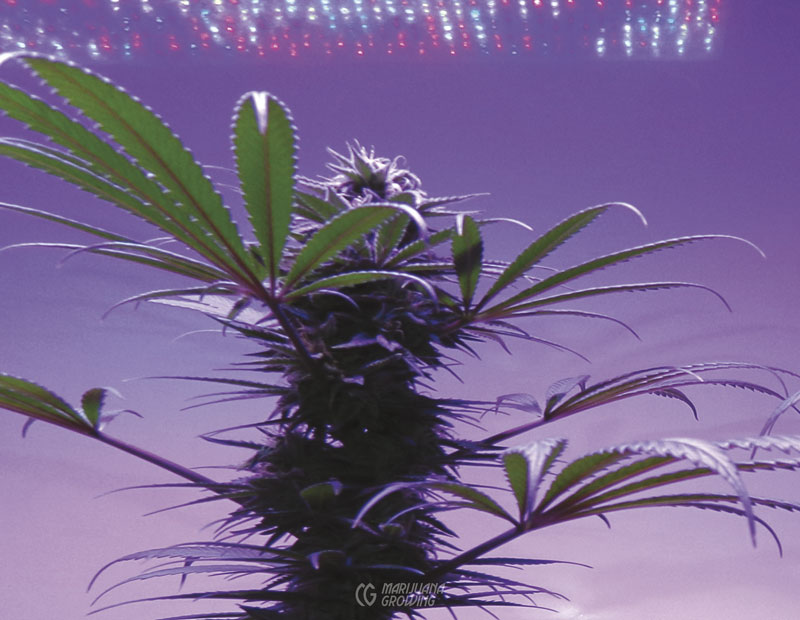

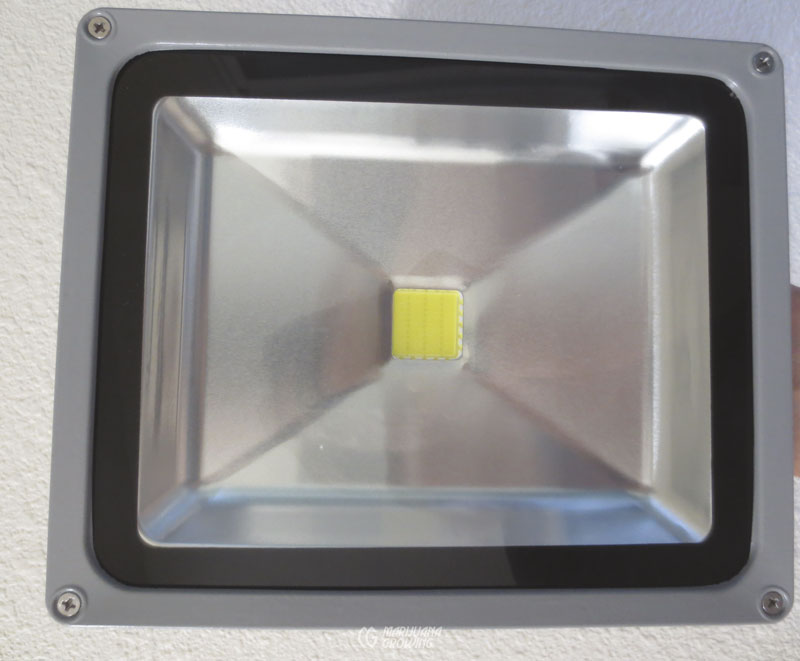

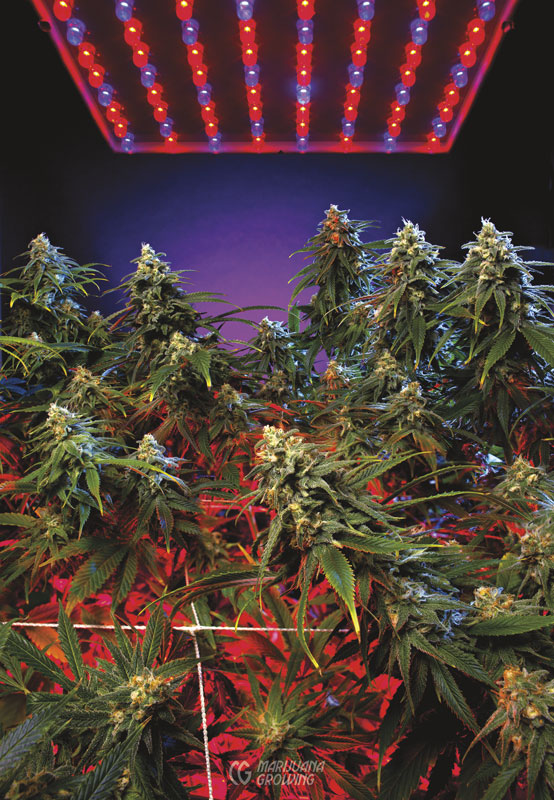

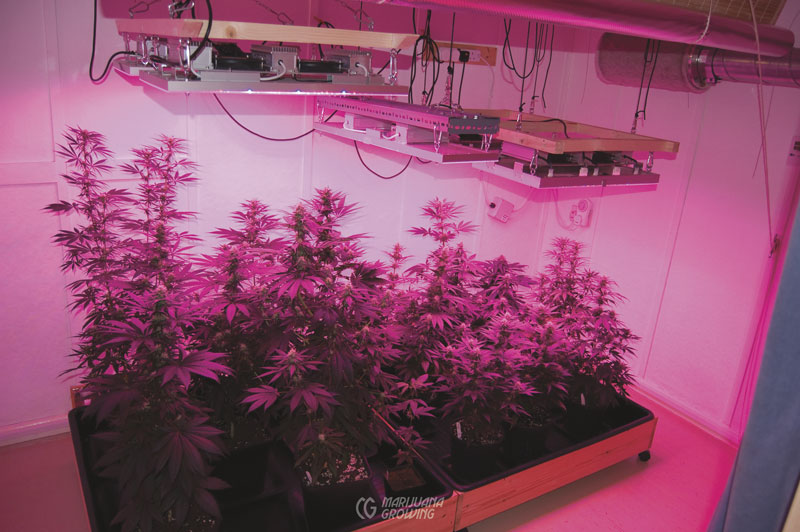

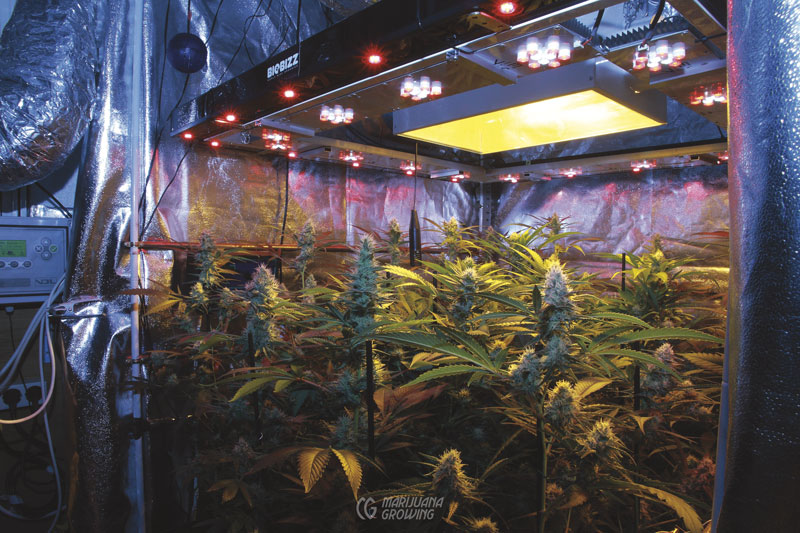

Medical cannabis can be grown indoors using exclusively artificial light sources such as fluorescent, compact fluorescent (CFL), light-emitting diode (LED), high-intensity discharge (HID), and light-emitting plasma (LEP) lamps. Each of the lamps has its strengths and weaknesses. The fluorescent, CFL, LED, and LEP produce less heat than HID lamps, but HIDs produce more lumens per watt (lm/W). Many of the lamps are available in a growing range of spectrums conducive to plant growth.

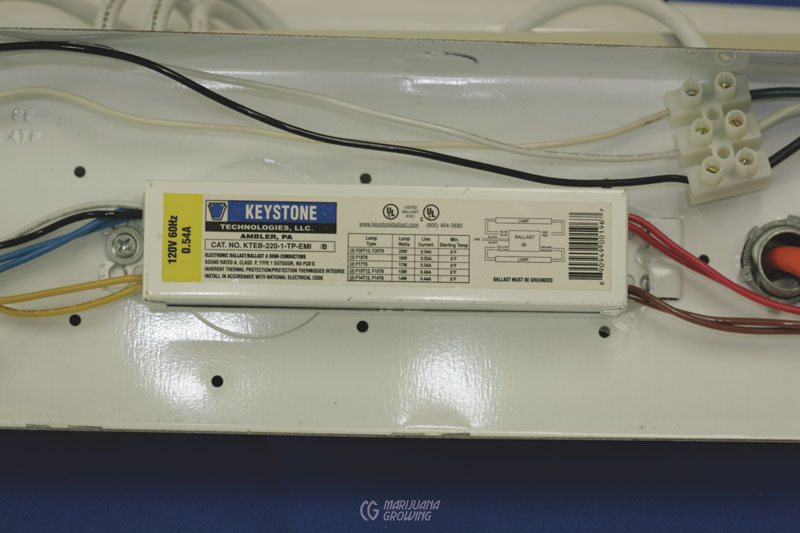

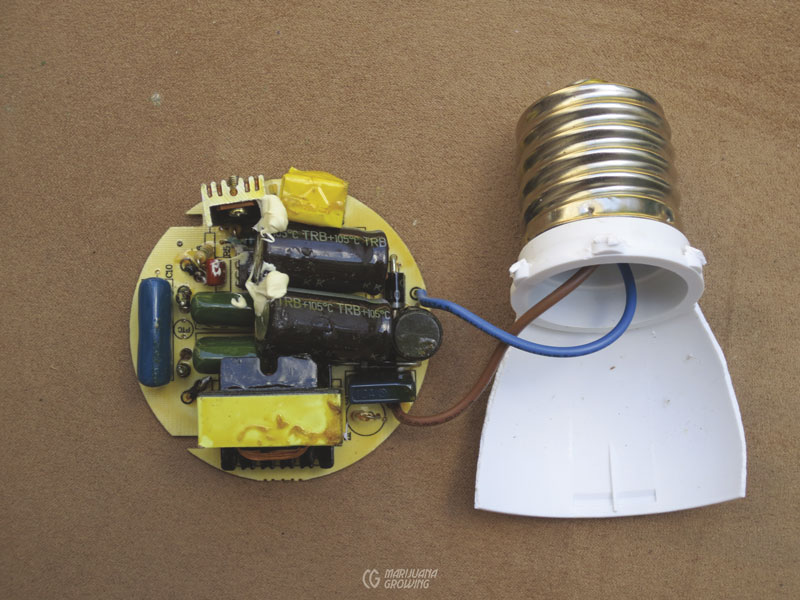

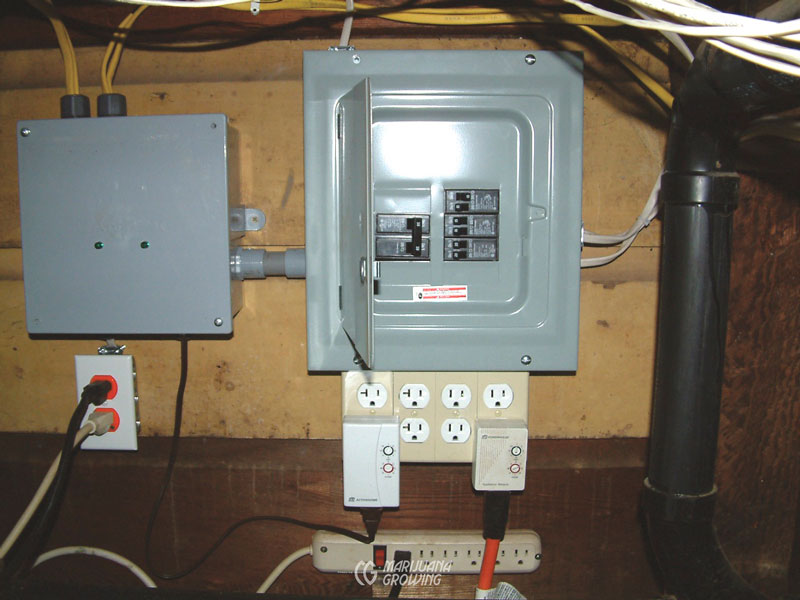

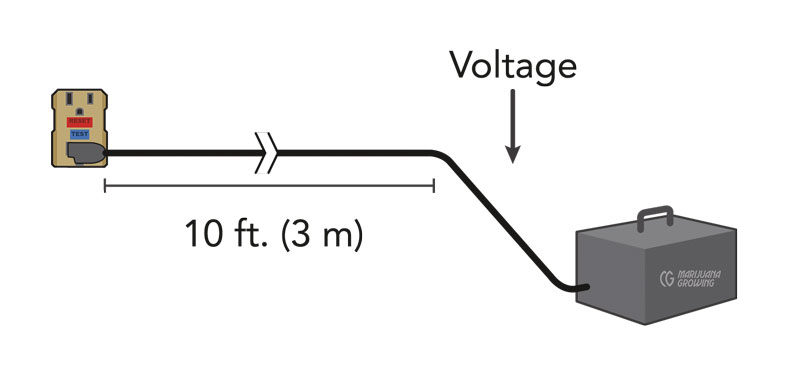

All lamps used for indoor growing require ballasts or some sort of extra circuitry to regulate line electricity before reaching the bulb. Old-fashioned heavy magnetic (analog) ballasts are losing popularity to ever-improving electronic ballasts and circuitry.

There are many different bulbs and ballasts, and there are many different setups for gardens. New manufactures have entered the market and most of the old-reliable manufacturers offer more products than ever before. Next we will discuss different lighting systems and all the pertinent gardening details. Find all the lamps in this chapter at local hydroponic stores and via Internet vendors.

High-Intensity Discharge (HID) Lighting Systems

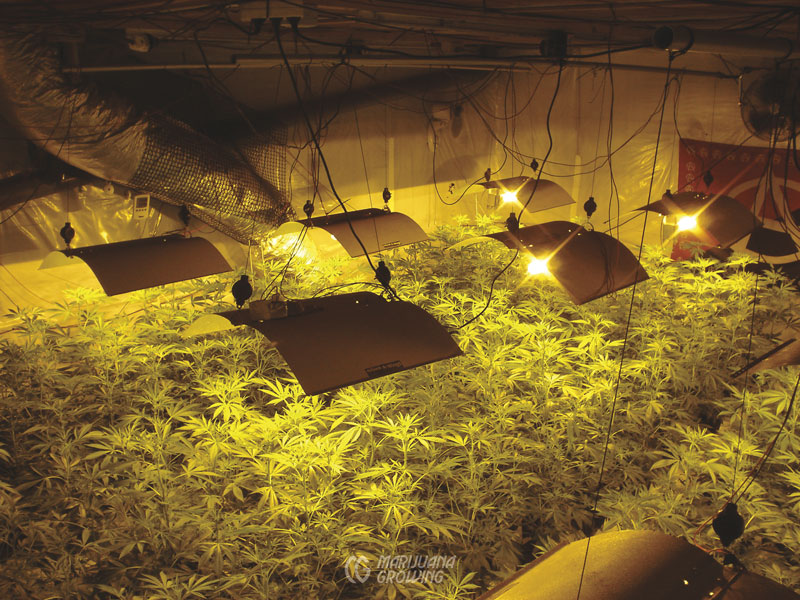

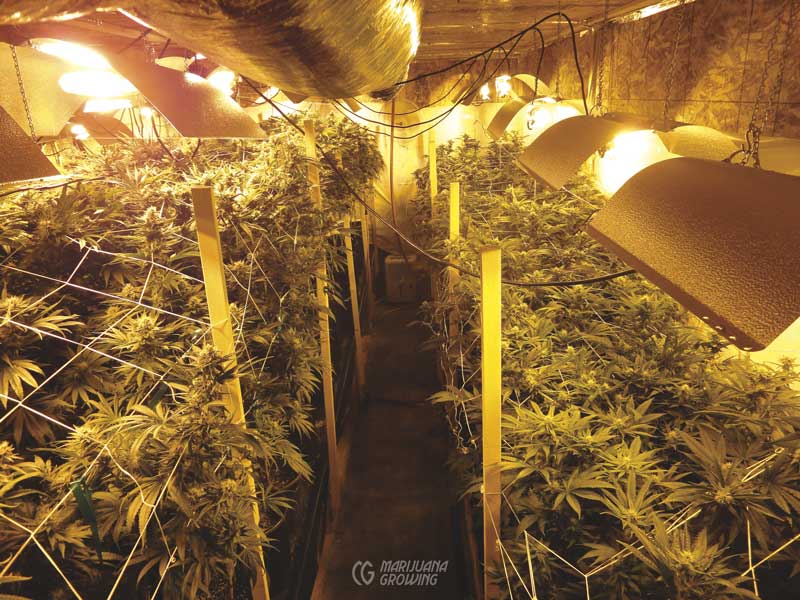

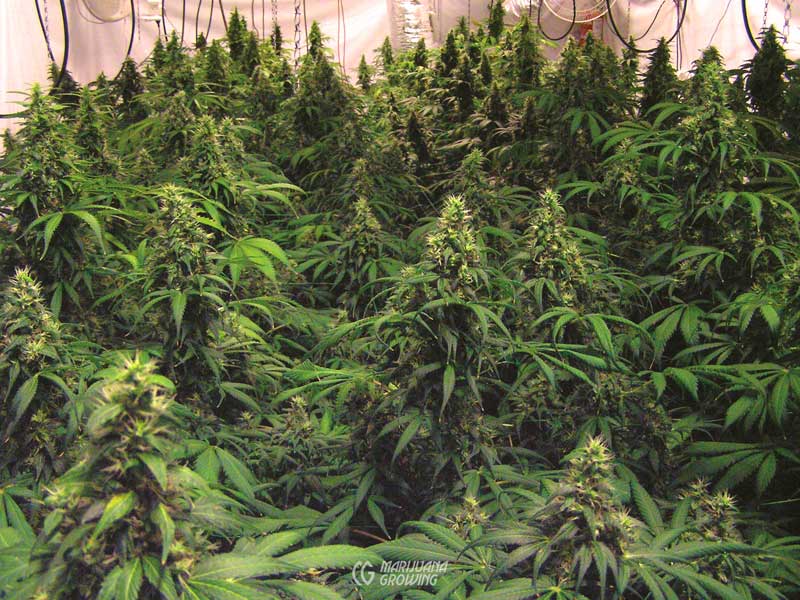

Medical cannabis gardeners are compelled to employ high-intensity discharge (HID) lamps indoors in lieu of natural sunlight when they are unable to garden outdoors or in a greenhouse. Many medical gardeners start cuttings and seedlings indoors under lights before moving them into a greenhouse or outdoors. To date, some HID lamps outperform other lamps in their combined lumens-per-watt efficiency, spectral balance, and brilliance.

The HID lamp family contains mercury vapor, metal halide (MH), high-pressure (HP) sodium, and conversion bulbs (MH to HPS and HPS to MH). Metal halide, HPS, and conversion lamps have a spectrum similar to actual sunshine and can be used to grow cannabis.

Popular HID wattages range from 150 to 1100. Smaller 150- to 250-watt bulbs are popular for small gardens measuring up to three feet square. Brighter 400- to 1100-watt lamps are favored for larger gardens. The 400- and 600-watt bulbs are most popular among European gardeners. North American gardeners favor 600- and 1000-watt bulbs. Super-efficient 1100-watt metal halides were introduced in 2000.

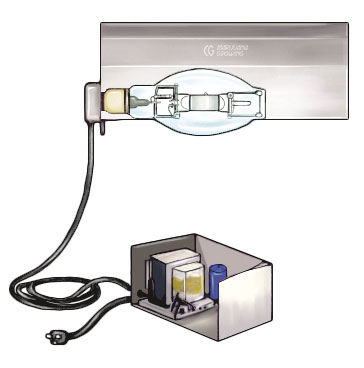

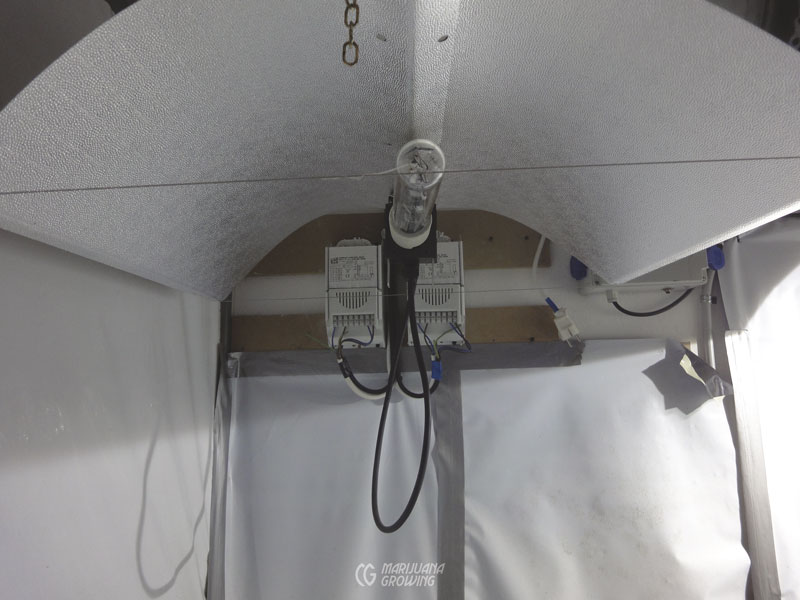

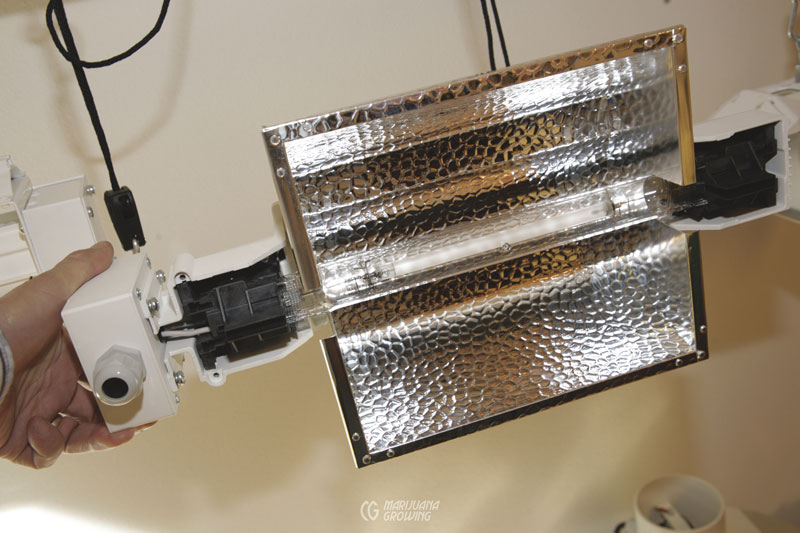

This simple cutaway drawing of a metal halide reveals the transformer and capacitor in a protective metal box. The bulb and hood are attached to the ballast with 14/3-wire and a mogul socket.

The brightest bulbs measured in lumens per watt are the metal halide and HP sodium bulbs. Originally developed in the 1960s, metal halides and HP sodium bulbs were characterized by one main technical limitation—the larger the bulb, the higher the lumens-per-watt conversion. For example, watt for watt, a 1000-watt HP sodium produces about 12 percent more light than a 400-watt HPS and about 25 percent more light than a 150-watt HPS. Scientists overcame this barrier when they developed the 600-watt HP sodium. Watt for watt, a 600-watt HPS produces 7 percent more light than the 1000-watt HPS. The “pulse start” metal halides are also brighter and much more efficient than their predecessors.

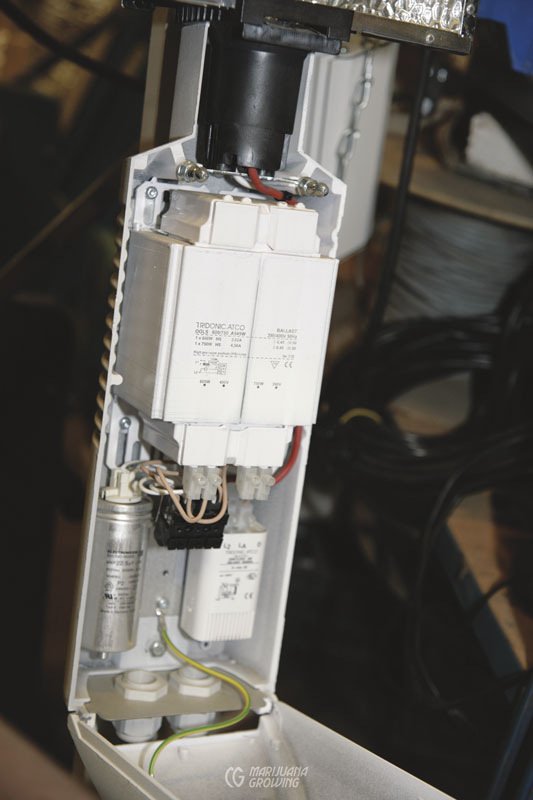

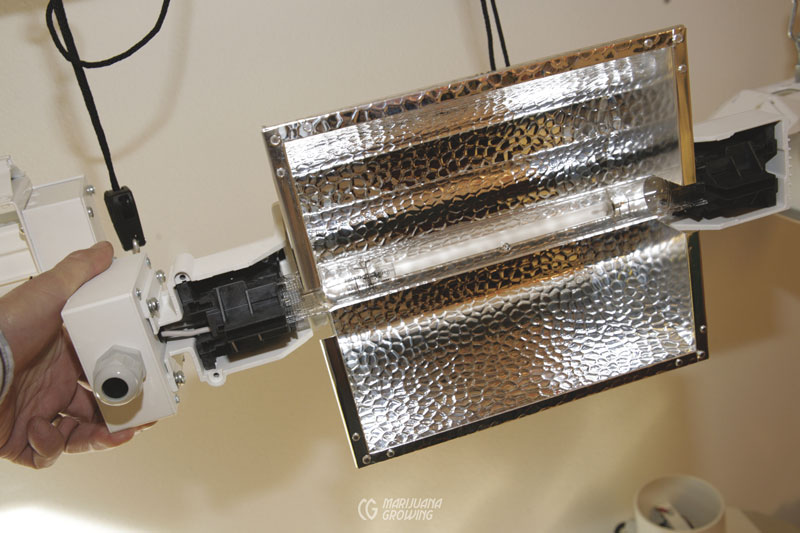

An HID light “system” consists of a ballast (transformer, capacitor, and starter) attached to an HID bulb and reflector. High-intensity discharge lamps produce light by passing electricity through ionized gas enclosed in a clear ceramic arc tube under very high pressure. The combination of chemicals sealed in the arc tube determines the color spectrum produced. The mix of chemicals in the arc tube allows metal halide lamps to yield the broadest and most diverse spectrum of light. The spectrum of HP sodium lamps is limited because of the narrower band of chemicals used to dose the arc tube. The arc tube is contained within a larger glass bulb. Most of the ultraviolet rays produced in the arc tube are filtered by the outer bulb. Some bulbs have a phosphor coating inside. This coating makes them produce a little different spectrum and fewer lumens. The outer bulb functions as a protective jacket that contains the arc tube and starting mechanism, keeping them in a constant environment, as well as absorbing ultraviolet radiation. Protective glasses that filter out ultraviolet rays are a good idea if you spend much time in the garden room.

Caution: To avoid serious damage to your eyes, never look at the arc tube if the outer bulb breaks. Turn off the lamp immediately.

An HID lamp requires a seasoning period of 100 hours of operation for all of its components to stabilize. If a power surge occurs and the lamp goes out or is turned off, it will take 5 to 15 minutes for the gases inside the arc tube to cool before restarting. Lamps last longer when started only once a day. Always use a timer to turn lamps on and off.

Typically, metal halides operate most efficiently in a vertical ±15degree position. When operated in positions other than ±15 degrees of vertical, lamp wattage, lumen output, and bulb life decrease; the arc bends, creating nonuniform heating of the arc tube wall, resulting in less-efficient operation and shorter life. There are special lamps made to operate in the horizontal or any other position other than ±15 degrees.

HID lamps may produce a stroboscopic (flashing) effect, making the light appear bright, then dim, bright, dim, etc. This flashing is the result of the arc being extinguished 120 times every second. Illumination usually remains constant, but it may pulsate a little. This is normal and nothing to worry about.

The number of HID lamp manufacturers has grown during the last few decades. Today HID bulbs are often made in China by unknown manufacturers. For example, go to http://www.alibaba.com/ and search for HID lights. HID bulbs made in different countries have diverse quality standards and laws or rules that are not always enforced. Substandard products result. General Electric, Iwasaki, Lumenarc, Osram/Sylvania, Philips, and Venture (SunMaster) continue to manufacture good-quality HID bulbs. Go to their websites and check the official statistics for each bulb.

Certain brands of bulbs may have better attributes than others. Indoor cannabis gardeners usually come to this conclusion because they purchase two different brands of bulbs and have better luck using one brand over the other. However, many manufacturers buy and use the same components, often manufactured by competitors.

The best way to ensure that bulbs emit adequate light all the time is to check the light output with a light meter.

Pulse-start metal halides operate in the same way as traditional metal halide bulbs, but their construction is slightly different. Traditional bulbs have an electrode at each end of the arc tube and an additional striker electrode close to one of the main electrodes. When the bulb starts, a short arc is formed between the striker electrode and the main electrode. This creates ionized gas that fills the tube and provides a path for an arc between the two main electrodes. A temperature-sensitive bimetallic strip acts as a switch and removes the striker electrode from the circuit when the light has fully lit. Pulse-start metal halides do not have a striker electrode; instead, their ballast contains an igniter circuit that provides a spike or pulse of electricity (1 kilovolt [kV] to 5 kV on a cold strike and up to 30 kV on a hot restrike) to start the arc.

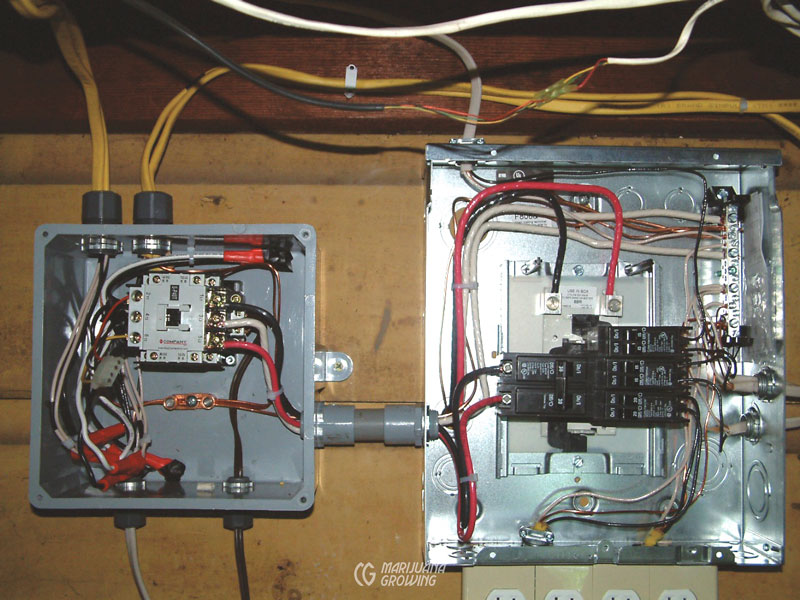

HID Ballasts

A ballast wired in between the lamp and the electrical power supply is necessary for HID lamps to regulate specific starting requirements and line voltage. Purchase the high-intensity discharge system—ballast, lamp, reflector, and electrical cords and plugs at the same time to ensure that they all function properly and are designed to work together. Always buy the proper ballast for HID bulbs. A good rule of thumb is that ballasts can be used only with bulbs they were designed for.

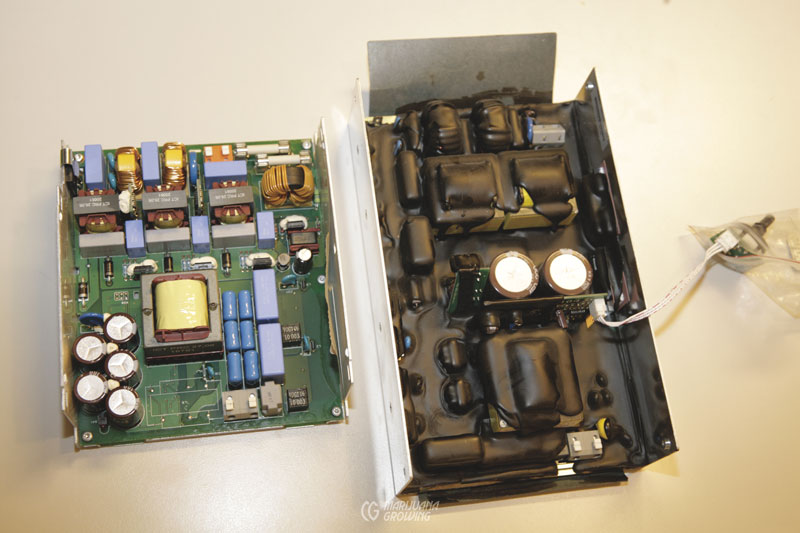

A ballast converts and regulates electricity. Ballasts can be either the old-style magnetic (analog or inductive) type or the newer electronic (digital) type. Inefficient conversion and regulation of electricity will result in lost power in the form of heat. Heat is an excellent measure of efficiency. Digital ballasts “leak” about 2.5 British thermal units per hour (Btu/h). Analog ballasts lose about 3.5 Btu/h. The difference is small, but it adds up over time. More electricity goes to the bulb and less heat is generated in the room.

After all the hype of lower electric bills when using electronic ballasts, our www.marijuanagrowing.com forum member JustThisGuy converted 16 analog ballasts to 16 digital ballasts. With analog ballasts the electric bill was $1,100 USD per month, and with digital ballasts it was $1,000 USD, a savings of about 9 percent. See chapter 15, Meters, for more information on measuring electricity use.

Analog (Magnetic) Ballasts

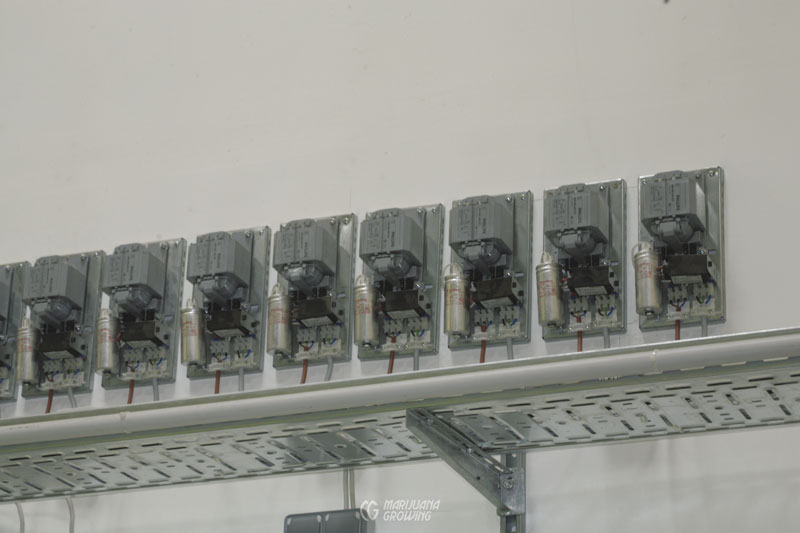

Analog or magnetic ballasts have been around for decades. They are available in wattages from 150 to 1100. Magnetic ballasts contain an inductor that consists of copper wire wound around an iron core (a series of metal plates stuck together by resin). This serves to regulate the current and voltage delivered to the lamp. A capacitor and (sometimes) a starter for lamps are mounted on a separate board. The ballast is wired in between the lamp and the electrical power supply. Magnetic ballasts weigh in at 30 pounds (13.6 kg) for a 400-watt and up to 60 pounds (27.2 kg) for a 1000-watt HPS.

Analog ballast kits contain a transformer core, capacitor (HPS and some metal halides), starter, containing box, and (sometimes) wire. You can purchase components separately from an electrical supply store, but doing so is often more work than it’s worth. If unfamiliar with electrical component assembly and reading wiring diagrams, purchase the assembled ballast in a package containing the lamp and reflective hood from one of the many HID retailers. Do not buy used parts from a junkyard or try to use a ballast if you are unsure of its capacity. Just because a bulb fits a socket attached to a ballast, does not mean that they will work efficiently together.

Analog ballasts generate noise and about 3.5 Btu/h of heat. As they age, the resin between plates in the core hardens and metal plates start to vibrate. Ballasts operate at 90ºF to 150°F (32.2ºC– 65.6°C). Touch a “strike anywhere” kitchen match to the side to check if it is too hot. If the match lights, the ballast is too hot and should be taken into the shop for assessment. Heat is the number one ballast destroyer.

Many types of ballasts are manufactured with a protective metal box. This outer shell safely contains the core, capacitor (starter), and wiring. Dampen noise by building another box around it. Make sure there is plenty of air circulation. If the ballast runs too hot, it will be less efficient, run more noisily, burn out prematurely, and maybe even start a fire.

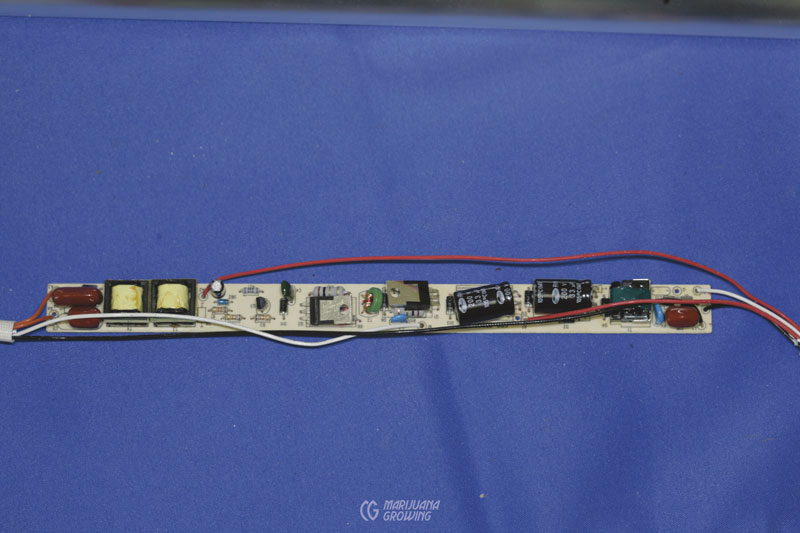

Electronic Ballasts

Electronic ballasts use a high-frequency oscillator circuit to provide a high-frequency current to drive the lamp. Electronic ballasts operate about 10 percent more efficiently than magnetic ballasts and consume a little less electricity to produce the same output. A microprocessor (CPU) that fine-tunes the electrical supply to the lamp can be found in some electronic ballasts, including those supplied by Lumatek.

High-frequency operation requires special “high-frequency” bulbs. Do not use a high-frequency lamp in analog or 50/60 cycle (hertz) ballast. And do not use a low-frequency bulb with a high-frequency electronic ballast. Operating requirements of each system are different, and interchanging bulbs or ballasts from digital to analog or vice versa will result in premature equipment failure.

The electrical input frequency, measured in hertz (Hz), to the ballast is 50 or 60 Hz. When the electricity leaves the ballast to go to the lamp, output frequency increases up to 4000 Hz. The high operating hertz virtually eliminates the stroboscopic effect and output does not fluctuate with input voltage. High operating frequencies prevent acoustic resonance and optimize lamp life. The result of the stable power supply is a brighter lamp.

HID lamps designed for digital ballasts also have stronger metals inside the bulb due to the higher operating frequencies and demands of a digital system. This is why it is so important to make sure ballasts and bulbs are designed to be used together.

Electronic ballasts are lightweight and run cool, generating about 2.5 Btu/h. They are designed to operate in environments less than 104°F (40°C).

Solid-state electronic ballasts have no moving parts and make little noise. Manufacturers often cover components in resin (a process called “potting”) to protect them from water, humidity, and other damage. This is very important in a garden environment. Mount ballasts on a small pad or rubber feet to subdue any noise caused by vibration.

Available in 150- to 1150-watt models, many electronic ballasts are able to modulate in-between wattages. For example, a 1000-watt ballast could work at different settings: 600, 750, 1000, or 1150 watts.

The wattage on some electronic ballasts can be changed. For example, a 1000- watt electronic ballast could run at wattages from 600 to 1150. Dial settings are adjusted to change the wattage of the lamp. Underdriving lamps works well but is less efficient electrically.

Multiple power outputs from ballasts enable use for different bulbs. Electronic ballasts can be adjusted to operate at different wattages. The “soft dim” switch requires 60 seconds for each increase or decrease in wattage. For example:

1000-watt: 600, 660, 750, 825, 1000, 1150

600-watt: 300, 400, 600, 660

400-watt: 250, 275, 400, 440

Electronic ballasts can drive a wide range of electronic lamps (EL) and increase their output by 10 to 15 percent, but increasing output overdrives the bulb and shortens its life.

The world of indoor plant lighting is changing all the time. Keep up with new developments in plant lighting at www.marijuanagrowing.com.

Ballast Features

Avoid purchasing ballasts with enclosed fans or timers. They run too hot, and the extra appliances tend to break or cause problems.

Ballasts can be attached to the light fixture or remote. The remote ballast offers the most versatility and is often the best choice for small HID gardens. A remote ballast is easy to move. Help control heat by placing a remote ballast on or near the floor to radiate heat in a cool portion of the garden room, or move the ballast outside the garden to cool the room. Do not place the ballast directly on a damp floor or any floor that might get wet and conduct electricity. Attached ballasts are fixed to the hood; they require more overhead space, are very heavy, and tend to create more heat around the lamp.

Attached ballasts have the benefit of using less electricity and creating a lower electronic profile around the garden. The electric cord between the ballast and the lamp consumes electricity, lowering lamp efficiency. It works like an antenna and emits a radio frequency signal that is very easy to pick up from afar. Thousands of luminaries can be operated in the same area.

A handle will make ballasts easier to move. A small 400-watt analog metal halide ballast weighs about 30 pounds (about 14 kg), and a large 1000-watt HP sodium ballast tips the scales at about 55 pounds (about 25 kg). This small, heavy box is very awkward to move without a handle.

Air vents allow a ballast to run cooler. The vents should protect the ballast’s internal parts and prevent water from splashing in.

Ballasts with a switch allow gardeners to use the same ballast with two different sets of lights. This wonderful invention is perfect for running two flowering garden rooms. The lights go on for 12 hours in one garden room while they are off in a second room. When the lights turn off in the first room, the same ballasts hooked to another set of lights in the second room are turned on. There must be a 10- to 15-minute pause between initiation of lights in each room.

There are also ballasts to run both metal halide and HP sodium systems. These dual-purpose ballasts are not as efficient as dedicated ballasts. They often overdrive the metal halide bulb, causing it to burn out prematurely after accelerated lumen output loss. If you have a limited budget and can only afford one ballast, it is more economical to use conversion bulbs to change spectrum. (See “Conversion Bulbs”).

Most magnetic ballasts sold by HID stores are “single tap,” and are set up for 120 volt household current in North America or 240 volts in Europe and other countries. Some “multi-tap” or “quad-tap” ballasts are ready for 120 or 240 volt service. North American ballasts run at 60 cycles per minute, while European counterpart runs at 50 cycles per minute.

European greenhouse HID lighting systems operate at 400 volts. Hobby lights were developed from professional lights that operate at 230 watts.

There is no difference in the electricity consumed by using either 120 or 240 volt systems. The 120 volt system draws about 9.6 amperes, and an HID on a 240-volt current draws about 4.3 amperes. Both use the same amount of electricity. Work out the details yourself using Ohm’s Law.

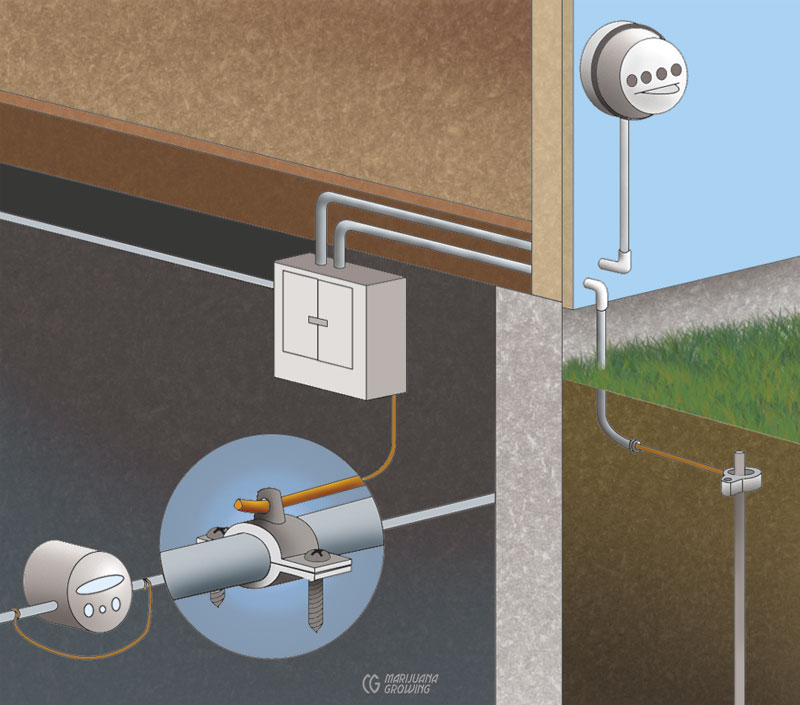

Ballast Safety

The ballast has a lot of electricity flowing through it. Do not touch the ballast when operating. Do not place the ballast directly on a damp floor or any floor that might get wet and conduct electricity.

Always place the ballast up off the floor, and protect it from possible moisture. The ballast should be suspended in the air or on a shelf attached to the wall. It does not have to be very high off the ground, just far enough to keep it dry.

Place the ballast on a soft foam pad to absorb vibrations and lower decibel sound output on analog ballasts. Loose components inside the ballast can be tightened to further deaden noise caused by vibrations. Train a fan on ballasts to cool them. Cooler ballasts are more efficient, and bulbs burn brighter. Always check with a qualified source such as a hydroponic store to ensure that the ballast is designed for a specific lamp. Do not try to mix and match ballasts and lamps.

Some industrial ballasts are sealed in fiberglass or similar material to make them weatherproof. These ballasts are not recommended for use indoors. They were designed for outdoor use where heat buildup is not a problem. Indoors, the weather-protection of the sealed unit is unnecessary and creates excessive heat and inefficient operation.

Purchase only quality ballasts that come with a guarantee. Read the fine print, and do not be tricked by misleading sales phrases such as “all components UL (or CSA, EMC, etc.) approved.” Each of the components could be UL, CSA, or EMC approved, but when the components are used together to operate a lamp, they are not UL, CSA, or EMC approved. Often components are approved, but not approved for the specific application.

To keep ballasts clean wipe them down with a damp cloth. Look for heat damage such as melted and burned wires. Take ballast to dealer immediately if signs of heat or malfunction occur. Often ballasts are sealed, and opening the ballast or breaking the seal will void the warranty.

When using a single ballast to light 2 lamps at 12-hour intervals, let it cool down before restarting. Run the lamp 12 hours then let the ballast cool for 15 minutes before restarting to operate the second 12-hour stint of light. Letting the ballast cool will help avoid burnout.

HID Bulbs

Ulbricht Sphere

An integrating sphere (aka Ulbricht sphere) is a hollow spherical cavity. The inside is covered with a diffuse reflective white paint. Its purpose is to uniformly diffuse or scatter light so that it is distributed equally to all points inside the sphere.

Measuring light in an Ulbricht sphere is the standard in photometry and radiometry. It measures light produced by a source where total (light) power can be acquired in a single measurement.

The number of new HID bulbs that appear on the market today is mind-boggling. Osram Sylvania, General Electric, Gavita, Philips, SunMaster, Fulham, and Venture are a few of the manufacturers that make and continue to develop new HID bulbs.

Not all HID bulbs are created equal. In fact, there are brighter brands that supply up to 15 percent more light than the closest competitor. The Philips Master GreenPower Plus TD EL 1000-watt lamp is the brightest lamp and emits more μmol than any other bulb. This exceptional HPS tubular lamp is secured at both ends, which allows a straight shot for the electricity to flow. Coupled with a bit longer arc tube, the free-flowing electricity makes the bulb generate more than 2000 μmol of light! Note that other bulbs, such as the Gavita Enhanced HPS 1000-watt, generate only 1750 μmols of light—12.5 percent less light.

Notable new bulbs have a high PAR rating and pulse-start metal halides.

High-intensity discharge bulbs are identified by wattage and by the size and shape of the outer envelope or bulb. They are further rated by voltage, ballasting requirements, lumen output, spectrum, etc.

Overall, HID bulbs are designed to be tough and durable, and new bulbs are tougher than used ones. Nonetheless, once the bulb has been used a few hours, the arc tube blackens and internal parts become somewhat brittle. After a bulb has been used several hundred hours, a solid bump will substantially shorten its life and lessen its luminescence.

HID Bulb Maintenance

Always keep the bulb clean. Wait for it to cool before wiping it off with a liquid glass cleaner and clean cloth, every 2 to 4 weeks. Dirt and fingerprints will lower lumen output substantially. Bulbs get covered with insect spray and salty water-vapor residues. This dirt dulls lamp brilliance just as clouds dull natural sunlight. Hands off bulbs! Touching bulbs leaves them with your hand’s oily residue. Baked-on residue weakens the bulb. Most gardeners clean bulbs with Windex or rubbing alcohol, and use a clean cloth to remove filth and grime; Hortilux Lighting advises cleaning bulbs with a clean cloth only.

Never remove a warm lamp. Heat expands the metal mogul base within the socket. A hot bulb is more difficult to remove, and it must be forced. Special electrical grease is available to lubricate sockets (Vaseline works too). Lightly smear a dash of the lubricant around the mogul socket base to facilitate bulb insertion and extraction.

The outer arc tube contains practically all the ultraviolet light produced by HIDs. If an HID should happen to break when inserting or removing it, unplug the ballast immediately and avoid contact with metal parts, to prevent electrical shock.

Pulse-start metal halide lighting manufacturers are required by the Energy Independence and Security Act of 2007 to meet certain efficiency standards. Effective January 1, 2009, standards require pulse-start metal halide lighting with a minimum ballast efficiency of 88 percent. Find ballast efficiency by dividing the lamp wattage by the operating wattage.

Lumen output diminishes over time. As the bulb loses brilliance, it generates less heat and can be moved closer to the garden. This is not an excuse to use old bulbs; it is always better to use newer bulbs. However, it is a way to get a few more months out of an otherwise worthless bulb.

Write down the day, month, and year you start using a bulb so you can better calculate when to replace it for best results. Replace metal halides after 12 months of operation and HP sodium bulbs after 18 months. Many gardeners replace them sooner. Always keep a spare bulb (in its original box) available to replace old bulbs. You can go blind staring at a dim bulb trying to decide when to replace it.

You may prefer to change bulbs according to manufacturer´s recommendations. Some companies recommend as often as once every 8 months, others at 12 months. You are best to measure the light output; when it has diminished 10 to 20 percent, change bulbs.

Bulb Disposal

All fluorescent, compact fluorescent, plasma, HID, and any bulbs that may contain mercury or some other heavy metal that should not escape into the environment. Take spent bulbs to the proper hazardous materials disposal site in your area. Do not toss bulbs into the trash.

- Place the bulb in a dry container, and then dispose of it at certified toxic waste dump facility such as a HAZMAT disposal site in the USA. Most countries have specific agencies that dispose of toxic waste.

- Lamps contain materials that are harmful to the skin. Avoid contact, and use protective clothing.

- Do not place the bulb in a fire.

Mercury Vapor Lamps

The mercury vapor lamp is the oldest and best-known member of the HID family. The HID principle was first used with the mercury vapor lamp around the turn of the 20th century, but it was not until the mid-1930s that the mercury vapor lamp was really employed commercially. Today they are too inefficient to consider as a light source for medical cannabis cultivation.

Mercury vapor lamps produce only 60 lumens per watt—and a poor light spectrum for plant growth. Lamps are available in sizes from 40 to 1000 watts. Bulbs have fair lumen maintenance and a relatively long life. Most wattages last up to 3 years at 18 hours of daily operation.

Bulbs usually require separate ballasts. There are a few low-wattage bulbs with self-contained ballasts. Uninformed gardeners occasionally try to scrounge mercury vapor ballasts from junkyards, and use them in place of the proper halide or HP sodium ballast. Trying to modify these ballasts for use with other HIDs will cause problems.

Metal Halide Bulbs and Ballasts

Metal Halide Bulbs

The metal halide HID lamp is still one of the most efficient sources of artificial white light available to gardeners today. Grow plants from seed through harvest with metal halide lamps. They come in wattages from 50 to 1100, and 1500 watts. They may be either clear or phosphor-coated, and all require a special ballast. The smaller 175- or 250-watt halides are very popular for closet garden rooms. The 400-, 600-, 1000- and 1100- watt bulbs are most popular with indoor gardeners. The 1500-watt halide is avoided due to its relatively short 2000- to 3000-hour life and its incredible heat output. American gardeners generally prefer the larger 1000-watt lamps, and Europeans seem to almost exclusively favor 400- and 600-watt lamps.

| LAMP | KELVIN TEMPERATURE |

| AgroSun | 3250 |

| Multivapor | 3800 |

| Sunmaster Warm Deluxe | 315 PAR |

| Sunmaster Natural Deluxe | 315 PAR |

| Sunmaster Cool Deluxe | 315 PAR |

| SolarMax | 7200 |

| MultiMetal | 4200 |

Caution! Do not mix and match ballasts and bulbs! Ballasts are designed to be used with specific bulbs. Using bulbs with improper ballasts will shorten the life of both components and could cause excessive heat or catch fire!

More and more new metal halide lamps are being developed and marketed every year. New technology and materials have opened the door to new lighting products. The intention of this book is to show the basics of light and electricity, and how cannabis interacts with light rather than to keep up with all the new lighting developments. For more current information on new lamps, ballasts, and reflective hoods, see www.marijuanagrowing.com.

Clear halides are most commonly used by indoor gardeners. Clear super metal halides supply the bright lumens for plant growth. Clear halides work well for seedling, vegetative, and flower growth. Phosphor-coated 1000-watt halides give off a more diffused light (and produce less light) but they emit less ultraviolet light than the clear halides. They produce the same initial lumens and about 4000 fewer lumens than the standard halide, and have a slightly different color spectrum. Phosphor-coated halides have more yellow, but less blue and ultraviolet light. Phosphor-coated bulbs were popular among gardeners in the 1990s.

The 1000-watt super clear halides are the most popular metal halides used to grow cannabis in North America. Compare energy distribution charts and lumen output of all lamps to decide which lamp offers the most light for your garden. Typically, a home gardener starts with one super metal halide.

Universal metal halide bulbs designed to operate in any position, vertical or horizontal, supply up to 10 percent less light and often have a shorter life.

Base Up (BU) and Base Down (BD) metal halide lamps must be vertical to operate properly. Horizontal (H) lamps must orient the arc tube horizontally to burn brightest.

Metal halide lamps are available in a variety of spectrums.

AgroSun and Sunmaster Warm Deluxe emit low (3000 Kelvin) color temperatures. The enhanced orange-red component promotes flowering, stem elongation, and germination while a rich blue content assures healthy vegetative growth. Visit www.growlights.com for more information.

The average life of a halide is about 12,000 hours, almost 2 years of daily operation at 18 hours per day. Many will last even longer. The lamp reaches the end of its life when it fails to start or come up to full brilliance. Electrode deterioration is greatest during start-up. Do not wait until the bulb is burned out before changing it. An old bulb is inefficient and costly. Bulbs lose at least 5 percent of their brilliance every year. Replace bulbs every 12 months or 5000 hours.

Metal Halide Ballasts

Read “About Ballasts.” Different ballasts are required for each type of lamp. Use a magnetic ballast to operate metal halide bulbs designed for use with them. An electronic ballast is made specifically for electronic high-frequency bulbs. Ballasts must be specific to certain lamps because their starting and operating requirements are unique. Electronic ballasts are more efficient and produce less heat than analog or magnetic ballasts.

High-Pressure Sodium Bulbs and Ballasts

Approximately 60 percent of HP sodium light is infrared or heat. All lamp power and light will be converted to heat as bulbs degrade over time.

HP Sodium Bulbs

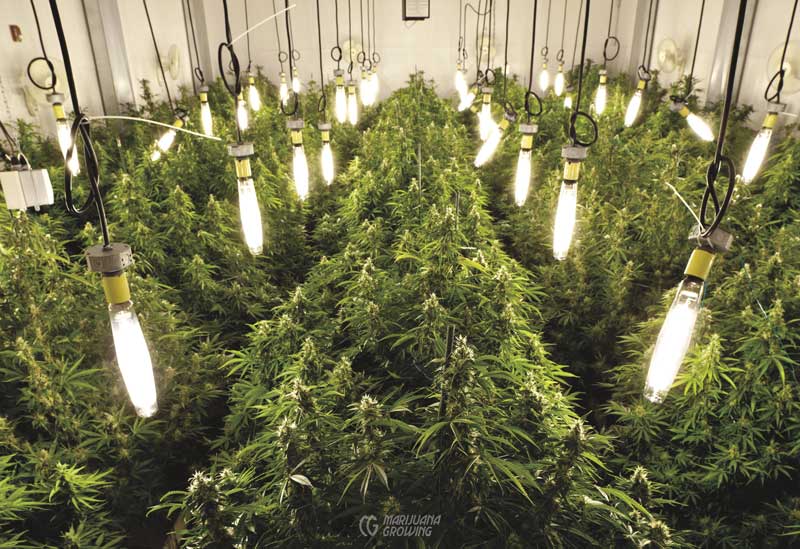

The high-pressure sodium (HPS) lamp is the most efficient source of artificial light available to medical cannabis gardeners today. HPS lamps come in wattages from 50 to 1000 watts. All require a special ballast. The smaller 175- or 400-watt HP sodium systems are very popular for closet garden rooms. The 400-, 600-, and 1000-watt bulbs are most popular with indoor and greenhouse gardeners.

HP sodium lamps emit a yellow-orange glow that could be compared to that of the harvest sun. Cannabis’s light needs change when blooming; it no longer needs to produce so many vegetative cells. Vegetative growth slows and eventually stops during flowering. The plant’s energy is focused on flower production so it can complete its annual life cycle. Light from the red end of the spectrum stimulates floral hormones within the plant, promoting flower production. In general, American gardeners use 1000- and 600-watt HP sodiums most often, while European gardeners use 400- and 600-watt HPS lamps.

Discount building stores often carry a good selection including 250- and 400- watt lamps. All HPS lamps will grow cannabis. Even though HPS lamps are brighter and will grow cannabis, the spectrum contains little blue and more yellow/orange. Lack of color balance makes plants stretch between internodes and experience more cultural and plague problems. But when grown properly, the lack of the proper spectrum does not necessarily diminish overall harvest.

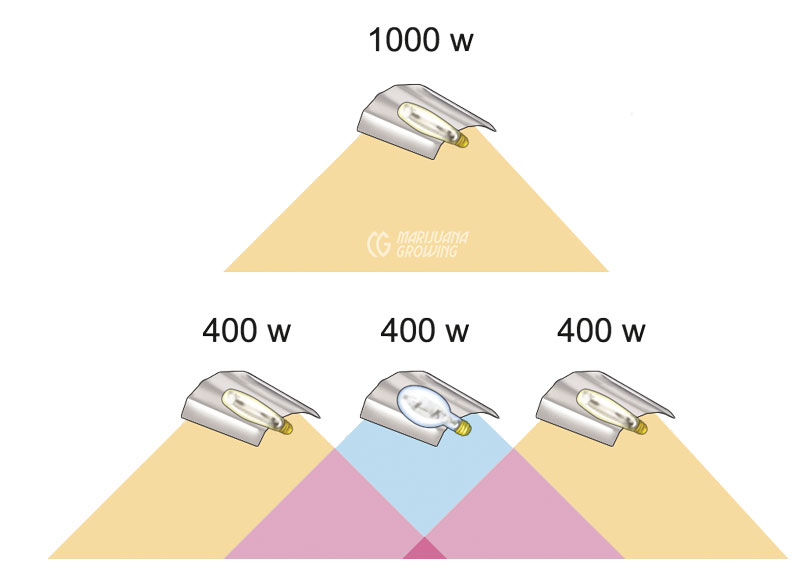

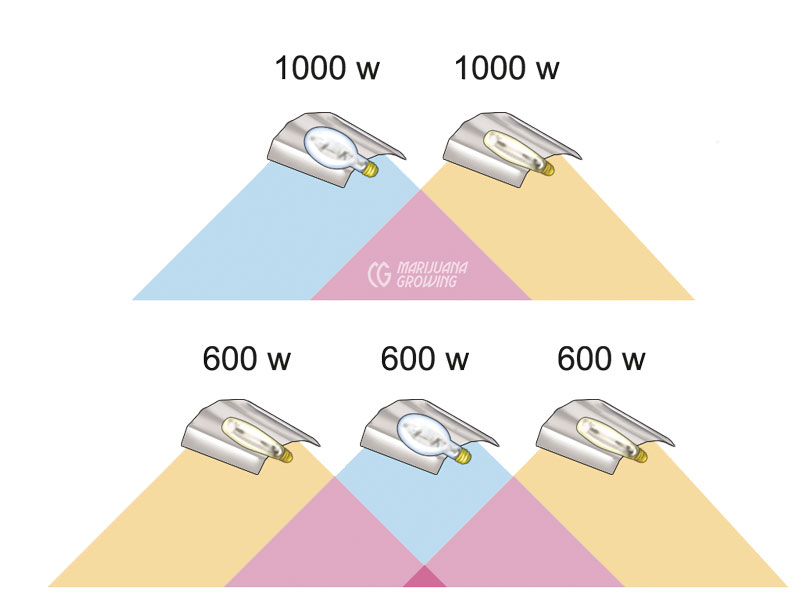

Gardeners with small rooms often retain the 1000-watt halide and add a 1000-watt HP sodium during flowering, when plants need more light to produce tight, dense buds. Adding an HPS lamp doubles available light and increases the red end of the spectrum. This 1:1 ratio (1 MH:1 HPS) is a popular combination in flowering rooms.

The average life of an HPS lamp is about 24,000 hours, with about 5 years of daily operation at 12 hours per day. Many last even longer. The lamp reaches the end of its life when it fails to start or come up to full brilliance. Electrode deterioration is greatest during startup. Do not wait until the bulb is burned out before changing it. An old bulb is inefficient and costly. Bulbs lose at least 5 percent of their brilliance every year. Replace bulbs every 24 months or 9000 hours.

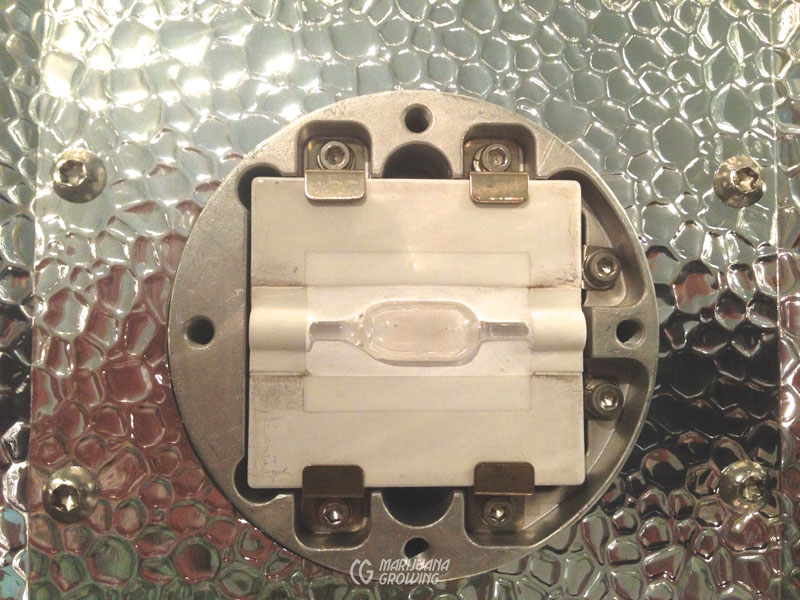

Double-ended 1000-watt HPS bulbs from Philips are the best grow lamp currently available. These bulbs are more efficient, and their arc tube is a little bit longer. Electricity flows from one end of the arc tube and out the other. This makes them inherently more efficient than bulbs that require electricity to travel farther. The new bulbs produce about 15 percent more light than single-ended bulbs. Since the bulb is attached at both ends, the arc tube is always mounted parallel to the reflector for maximum efficiency and reflection.

The 600-watt high-pressure sodium lamp produces 90,000 initial lumens. HPS lamps are available in wattages from 35 to 1000. The Philips GreenPower 400v, 600-watt EL (electronic lamp) has the highest PAR light output rating and more than 95 percent light maintenance.

The 430-watt Son Agro by Philips was designed to augment natural sunlight in greenhouses. The bulb produces a little more blue light, about 6 percent, in the spectrum. Adding a touch more blue light helps prevent most plants from becoming leggy.

High-pressure sodium lamps are manufactured by: GE (Lucalox), Sylvania (Lumalux), Westinghouse (Ceramalux), Philips (Son Agro), Iwasaki (Eye), and Venture (high-pressure sodium). Many more HPS bulbs are manufactured by others in China. Check out different Chinese manufacturers and their manufacturing standards. Chinese products are not necessarily bad; in fact, several of the above companies manufacture bulbs or components in China.

End of Life

HP sodiums have the longest life and best lumen maintenance of all HIDs. Over time the sodium bleeds out through the arc tube. The sodium-to-mercury ratio changes and the voltage in arc rises. The lamp warms up and goes out. The sequence is repeated, signaling the end of the lamp’s life, which is about 24,000 hours—five years at 12 hours daily use.

Dispose of bulbs in an approved hazardous waste facility.

HP Sodium Ballasts

Read “About Ballasts.” A special ballast is specifically required for each wattage of HP sodium lamp. Each wattage lamp has unique needs, including operating voltages during startup and operation that do not correspond to similar wattages of other HID lamps. Magnetic HPS ballasts contain a heavy transformer that is larger than that of a metal halide, a capacitor, and an igniter or starter. Electronic ballasts are much lighter in weight and more compact, and they consume less power than analog ballasts. They also require a specific bulb that is designed for high-frequency output electronic ballasts. Purchase complete HPS systems from a reputable source.

Self-contained units that have an integrated solid-state electronic ballast, a lamp, and a reflector in a single enclosed unit produce very little EMI (electromagnetic interference, aka radio frequency [RF] interference). Large greenhouses can use up to 10,000 lamps with no RF interference.

Conversion Bulbs

Conversion, or retrofit, bulbs increase lighting options on a budget. One type of conversion bulb allows you to utilize a metal halide (or mercury vapor) system with a bulb that emits a light spectrum similar to that of a HP sodium bulb. The bulb looks like a cross between a metal halide and an HP sodium. While the outer bulb looks like a metal halide, the inner arc tube is similar to that of an HP sodium. A small igniter is located at the base of the bulb. Other conversion bulbs retrofit HP sodium systems to convert them into virtual metal halide systems.

Conversion bulbs are manufactured in 150, 215, 360, 400, 880, 940, and 1000 watts. You do not need an adapter or any additional equipment. Simply screw the bulb into a compatible ballast of comparable wattage. Conversion bulbs operate at a lower wattage and are not as bright as HP sodium bulbs. Although conversion bulbs have less blue, they are up to 25 percent brighter than metal halide systems and their lumens-per-watt conversion is better than that of super metal halides. The 940-watt conversion bulb has a lumens-per-watt rating of 138. Similar to the HP sodium lamp, the conversion bulb has a life expectancy of up to 24,000 hours. Unlike most high-pressure sodium lamps which flicker on and off near the end of their lives, conversion bulbs go off and remain off at the end of their lives.

Although conversion bulbs are not inexpensive, they are certainly less expensive than an entire HP sodium system. For gardeners who own a metal halide system, or who deem metal halide the most appropriate investment for their lighting needs, conversion bulbs offer a welcome alternative for bright light. In the United States, CEW Lighting distributes Iwasaki lights. Look for their Sunlux Super Ace and Sunlux Ultra Ace lamps.

Venture, Iwasaki, and Sunlight Supply manufacture bulbs for conversion in the opposite direction—from high-pressure sodium to metal halide. Venture’s White-Lux and Iwasaki’s White Ace are metal halide lamps which will operate in an HP sodium system. The 250-, 400-, and 1000-watt conversion bulbs can be used in compatible HPS systems with no alterations or additional equipment. If you own a high-pressure sodium system but need the added blue light that metal halide bulbs produce, these conversion bulbs will suit your needs.

Many gardeners have great success using conversion bulbs. If you have a metal halide system but want the extra red and yellow light of an HP sodium lamp to promote flowering, simply buy a conversion bulb. Instead of investing in both a metal halide and an HP sodium system, you can rely on a metal halide system and use conversion bulbs when necessary, or vice versa.

HP Sodium to Metal Halide

Several companies make HPS to MH conversion bulbs, including the Sunlux Super Ace and Ultra Ace (Iwasaki) and Retrolux (Philips). The bulb emits an HP sodium spectrum with a metal halide system. These bulbs make it possible to use a metal halide ballast and get the same spectrum as an HP sodium lamp. Lumens-per-watt efficiency is traded for the convenience of using these bulbs. A 1000-watt HP sodium bulb produces 140,000 initial lumens. A MH to HPS conversion bulb produces 130,000 initial lumens. If you only want one lamp, a conversion bulb is a fair choice.

Metal Halide to HP Sodium

Metal halide to high-pressure sodium bulbs are manufactured by several companies, including the White Ace (Iwasaki) and White Lux (Venture). They have an MH spectrum and are used in an HPS system. The bulb converts from HPS to MH and produces 110,000 initial metal halide lumens.

Fluorescent Lamps, Ballasts, and Fixtures

Fluorescent Bulbs

Fluorescent bulbs (tubes) come in a wide variety of lengths, from 6 inches to 8 feet (15.2–243.8 cm). Two- and 4-foot (60–121.9 cm) tubes are easy to handle, readily available, and the most popular. Circular (T9) and U-shaped bulbs (B = bent) are also available.

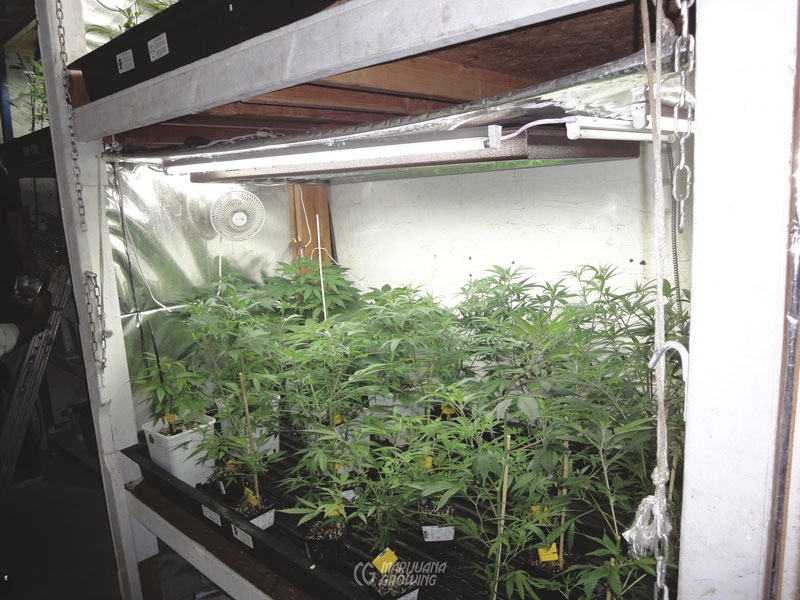

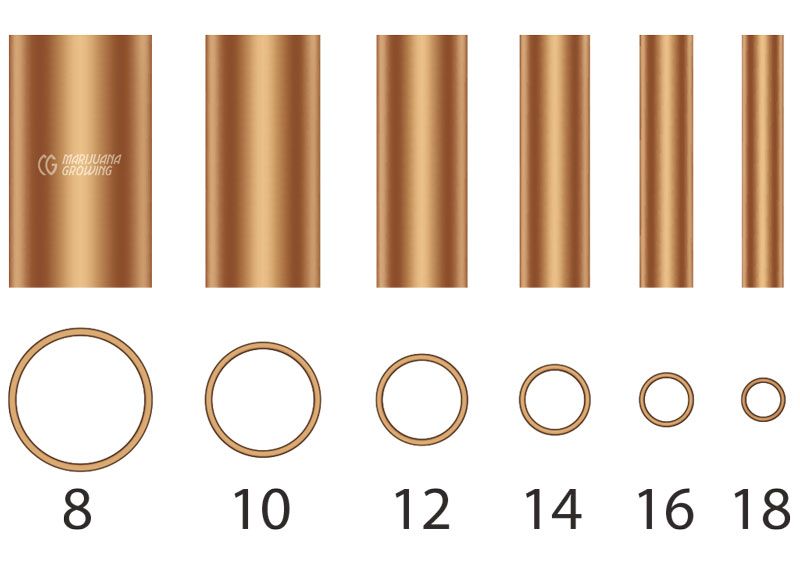

Fluorescent bulbs are available in at least 7 different diameters. T2 bulbs are the smallest and T4, T5, T8, T9, T12, and T17 (Power Twist) are each progressively larger in diameter. Many medical gardeners still use inexpensive reliable T12 lamps grow cuttings, seedlings and small vegetative plants. They supply cool, diffused light in the proper color spectrum to promote root growth. Other more brilliant fluorescents include T5 high output (HO), VHO and T8 HO, lamps. They are being used in gardens from seed through harvest.

HO = high output

VHO = very high output

XHO = extra high output

The average lumen output of a 4-foot (121.9 cm) 40-watt T12 is 2800 lumens per watt. A 32 watt T8 bulb yields 100 lumens per watt and supplies 100 average lumens. A 54 watt T5 throws 5000 average lumens, 92 lumens per watt.

Fluorescents produce much less light than HIDs and must be very close (2 to 4 inches [510 cm]) to the plants for best results. The light emission is strongest near the center of the tube, and somewhat less at the ends.

Fluorescent lamps are available in a variety of spectrums, from 2700 to 6500 K, including Warm White, Neutral White, Cool White, Full Spectrum, Daylight, and so forth, as listed at left.

Fluorescent lighting manufacturers include GE, Osram/Sylvania, and Philips.

The three main fluorescent tubes used by gardeners include T12, T8, and T5. The T12 and T8 bulbs were developed in the 1930s. The T12s met with immediate success; T8s became popular in the late 1980s. Today, T5 and T8 bulbs are more efficient than ever and often used to grow cannabis from clone or seedling through harvest.

Designed in the 1990s, T5 bulbs are the brightest of the fluorescent lamps. The full-spectrum, high-intensity, fluorescent T5 tubes come in high output (HO, 54 W), very high output (VHO, 95 W), and extra high output (XHO, 115 W). The intensely bright new spectrum is designed specifically for plant growth. The VHO and XHO lamps produce more heat and are more difficult and expensive to manufacturer than lower-output bulbs.

The T5 tubes are smaller and will fit in narrow spaces. The size makes for more accurate control of light direction with a reflective hood. Tubes are also rated as high efficiency (HE) and high output (HO), but the latter has lower efficiency.

High-output lamps are driven at a higher current and are brighter. The ends on the connecting pins are unique so they cannot be used in the wrong fixture. High-output bulbs are labeled HO, or VHO for very high output. The T5 lamps render peak light output at 95°F (35°C). The T8 and the T12 lamps provide peak light output at a 77°F (25°C). The bulbs run most efficiently and last longest when operated within the proper temperature range.

A fluorescent lamp consists of a glass tube coated on the inside with light-emitting phosphors and filled with a low-pressure mercury vapor. An electric current is passed through the tube, exciting the mercury vapor and causing it to emit UV light. This UV light causes the coating of the tube to fluoresce, giving off visible light. The mix of phosphorescent chemicals in the coating and the gases contained within determines the spectrum of colors emitted by the lamp. The quality of the phosphors and manufacturing process are essential to a lamp that will maintain true brilliance for a long time.

Old-fashioned T12 and T8 lamps are inefficient halophosphate tubes that do not render colors well. Today tri-phosphor and multi-phosphor tubes dominate the marketplace, because they are much more efficient and retain their properties well over time. A simple test with a light meter showed that inexpensive brand-new VHOs produced 30 percent less lumens than the phosphor and multiphosphor tubes.

Be very cautious when purchasing inexpensive lamps that use phosphorous from China rather than quality phosphorus (tri-phosphorous) from Japan and a few other places. Phosphorous from China generally does not hold the lumen or blue of the 6.5 K lamps. Lumen degradation occurs rapidly. Controlled studies found that inexpensive lamps start with very high lumens but can drop off by over 30 percent in a few months. Check bulbs regularly to ensure they are up to full brilliance.

Using fluorescents along with HIDs is awkward and problematic. When using them in conjunction with HIDs, fluorescents must be very close to plants to provide enough intense light for plant growth. Fixtures may also shade plants from HID light and generally get in the way.

| LAMP | USA | LIFE HOURS | WATTS | KELVIN TEMP. | LUMENS |

| Warm White | T12 | 24000 | 40 | 2700 | 2200 |

| Neutral White | T12 | 24000 | 40 | 3500 | 2200 |

| Cool White | T12 | 24000 | 40 | 4100 | 2200 |

| Full Spectrum | T12 | 24000 | 40 | 5000 | 2200 |

| Agrosun T12 | T12 | 24000 | 40 | 5850 | 2450 |

| AgroBrite T12 | T12 | 24000 | 40 | 6400 | 2200 |

| Spectralux T8 HO | T8 HO | 20000 | 54 | 6500 | 2700 |

| Ecolux T8 HO | T8 HO | 20000 | 54 | 6500 | 2700 |

| Spectralux T5 HO | T5 HO | 20000 | 54 | 3000 and 5000 | 5000 |

| Spectralux T5 VHO | T5 VHO | 20000 | 54 | 3000 and 6500 | 5000 |

| GE Starcoat T5 HO | T5 HO | 20000 | 54 | 3000 and 6500 | 5000 |

| Philips T5 Alto HO | T5 Alto HO | 20000 | 54 | 3000 | 5000 |

| GE Starcoat T5 HO | T5 HO | 20000 | 54 | Warm | 5000 |

| USA | Inches | Millimeters |

| T2 | 0.25 | 7 |

| T4 | 0.5 | 12 |

| T5 | 0.625 | 15.875 |

| T8 | 1 | 25.4 |

| T9 | 1.125 | 28.575 |

| T12 | 1.5 | 38.1 |

| T17 | 2.125 | 53.97 |

End of Life

Fluorescents blacken with age, losing intensity. Replace bulbs when they reach 70 to 90 percent of their stated service life listed on the package or label. A flickering light is about to burn out and should be replaced. Life expectancy is around 9000 hours (15 months at 18 hours’ daily operation).

The end-of-life failure mode for fluorescent lamps varies depending on their ballasts and on how the lamps are used. A lamp that turns pink with black burns on the ends of the tube lacks mercury.

A main reason that a lamp flickers is as a result of poor electrical connections.

Change the starter on older fluorescent fixtures. The starter is the little round tube that sticks into the fixture at one end of the bulb. Starters are inexpensive and have about the same life as a bulb. A new bulb will last a short time with an old starter that is on its last leg.

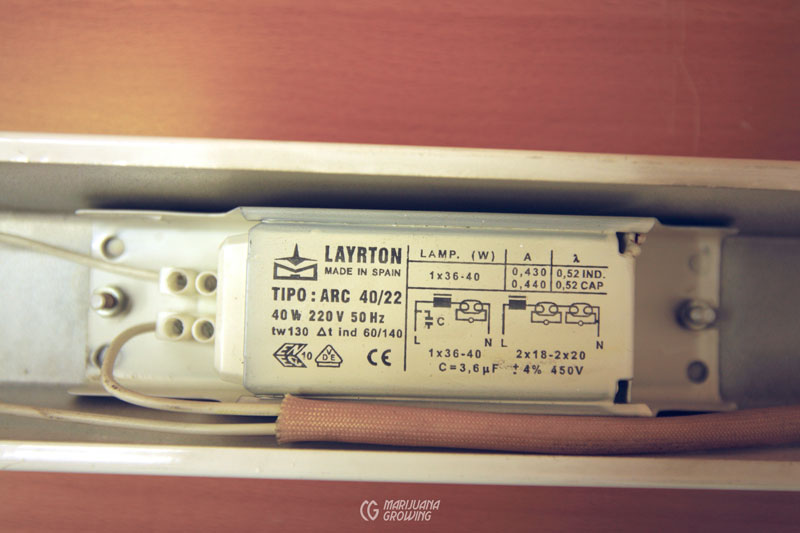

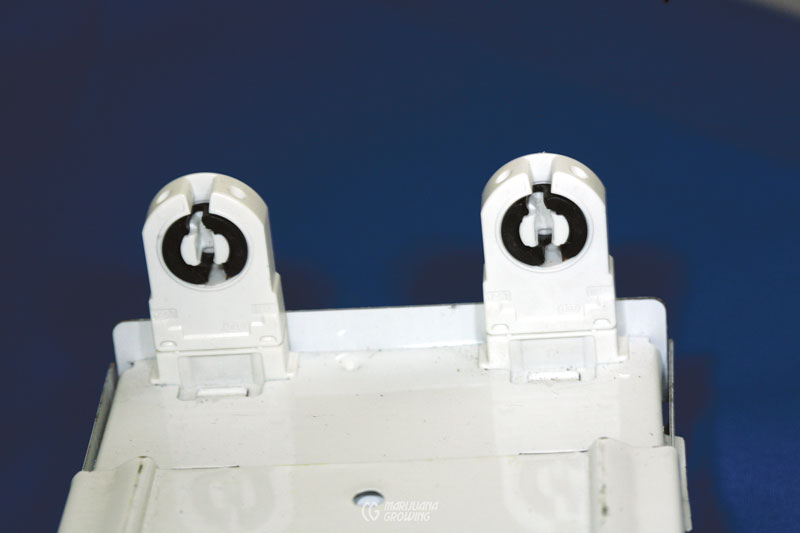

Fluorescent Ballasts

Each fluorescent lamp requires a specific ballast to regulate electricity before reaching the bulb. Fluorescents require an appropriate fixture containing a small ballast to regulate electricity and household electrical current. The tube type should always match the markings on the light fixture. Ballasts are rated for the size of lamp and power frequency. Ballasts can also include a capacitor to correct the power factor. The fixture is usually integrated into the reflective hood. The ballast is located far enough away from fluorescent tubes that plants can actually touch them without being burned.

Many of the T12 and T8 fixtures use old-fashioned magnetic ballasts. Newer T5, T8 and T12 fluorescents use electronic ballasts. Gardeners prefer slimmer T8 and T5 bulbs with electronic ballasts because they run cooler, electricity cycles faster, and lights do not flicker. Fluorescent light fixtures cannot be connected to dimmer switches intended for incandescent lamps.

Self-starting “rapid start” ballasts eliminate voltage spike when they are properly grounded. There are “instant start,” “rapid start,” “quick start,” “semi-resonate start,” and “programmed start” ballasts. The old-fashioned semi-resonate start lamps are the slowest to ignite; some of them even require a separate starter. All of the others strike and start lamps much faster. Programmed start ballasts are found in premium fixtures. Fixtures and lamps do take 5 to 10 minutes to warm up.

One of the main problems with fluorescent lighting is ballast incompatibility with the bulb. Some manufacturers use ballasts and lamps because they are the least expensive, not because they are designed for specific applications. Another example comes from gardeners: running a T8 tube with a ballast for a T12 will reduce lamp life and can increase energy consumption.

Analog Ballasts

Analog (magnetic) ballasts are simple, consisting of a copper wire winding on a laminated magnetic core. They are heavy and radiate almost all heat produced by the system. Analog ballasts consume about 10 percent of the system’s electricity. A wiring diagram is usually glued on the ballast. Simple wiring is also provided.

These ballasts will normally last 10 to 12 years. The end of the magnetic ballast’s life is usually accompanied by smoke and a miserable chemical odor. When the ballast burns out, remove it and buy a new one to replace it. Be very careful if the ballast has brown slime or sludge on or around it. This sludge could contain carcinogenic PCBs. If the ballast contains the sludge, dispose of it in an approved location for hazardous waste.

Electronic Ballasts

Electronic ballasts run much cooler, consume little electricity, and are lightweight. They are normally located within the lamp fixture. Electronic ballasts are very quiet, with no annoying hum. Electronic ballasts use transistors to alter incoming electricity into high-frequency alternating current (AC), and regulate the current flow in the lamp simultaneously. Efficacy of a fluorescent lamp rises by almost 10 percent at a frequency of 10 kHz, compared to efficacy at normal power frequency. Electronic ballasts are also called digital ballasts because they are controlled by a microcontroller or similar hardware. The electronic controller dims lights and maintain constant light levels—no flickering.

Electronic ballasts typically work in rapid start or instant start mode. Low-cost ballasts start slowly. More expensive ballasts use programmed start, which ignites the lamps quickly.

At the end of life, electronic ballasts simply stop. No drama. One of the most common causes of lamp failure is due to a lower voltage capacitor and other parts that cost less are installed. The stress causes premature failure. Always purchase quality equipment.

Most electronics failures happen early in life and diminish thereafter. High temperatures shorten electronic ballast life. Typically for every 50 degrees the temperature rises, the ballast life is cut in half. Keep the temperature range within the operating boundaries, normally at about 77°F (25°C) in most countries. Dispose of electronic ballasts in an approved hazardous waste dump.

Fluorescent Fixtures

A “shop light” fixture/reflector that holds two 40-watt T12 fluorescent tubes and ballast available at hardware stores is perfect for growing cuttings and seedlings until they are about six inches (about 15 cm) tall. A more substantial fixture will be necessary for higher light output using brighter bulbs. Many used shop light fluorescent fixtures are generally available and usually acceptable to use.

If your fluorescent fixture does not work, first unplug the electricity. Next check all electrical connections to make sure they are secure. If you see any signs of burning or heat, take the fixture to the nearest electric store and ask for advice. Make sure they test each component and tell you why it should be replaced. It might be less expensive to buy another fixture.

Fluorescent Bulb Disposal

The US Environmental Protection Agency (EPA) and other similar agencies around the world classify fluorescent lamps as hazardous waste because bulbs contain mercury and ballasts contain other unpleasant stuff. They must be taken to a qualified facility for recycling or safe disposal of toxic waste.

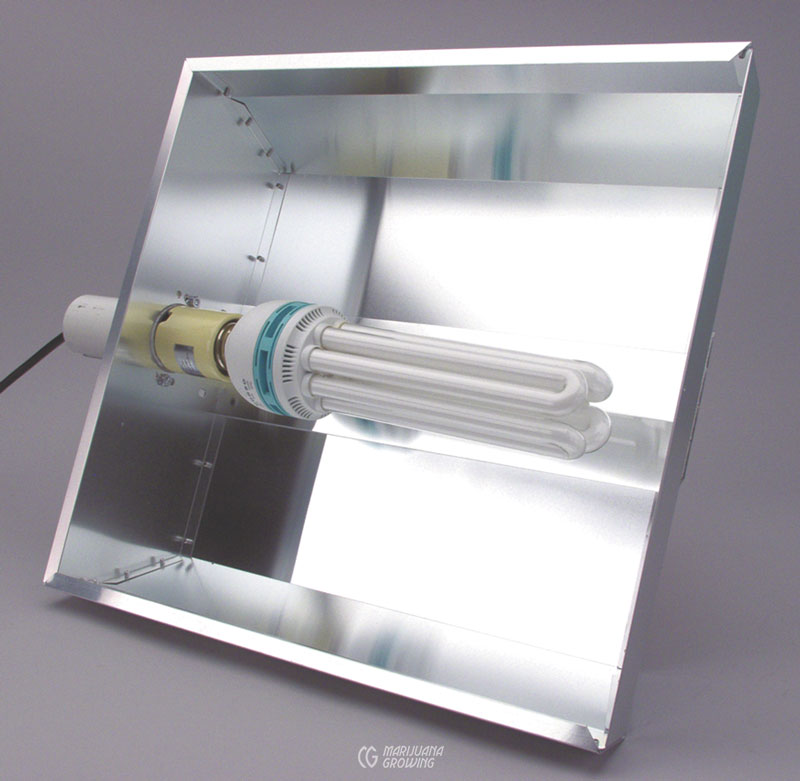

Compact Fluorescent Lamps (CFL)

Most consumers know compact fluorescent lamps (CFL) as the new energy-efficient replacement for household incandescent lightbulbs, the ones that Thomas Edison invented. The characteristic helical spiral was developed in the mid-1970s for low wattage CFLs. By the 1980s CFLs with electronic ballasts were available. Other configurations—horseshoe, round and flat (butterfly) were later developed. For example, readily available 65-watt floodlights are configured flat so that light emitted is either direct or easily reflected. Larger wattages, 65+, can be used to grow medicinal cannabis from seed through flowering. Some of the smaller wattages fit into household incandescent lightbulb sockets. Larger 95-, 125-, 150-, and 200-watt bulbs require a larger mogul socket. Common wattages used for growing cannabis include 55, 60, 65, 85, 95, 120, 125, 150, and 200. Regardless of wattage, CFLs must warm up for about 5 minutes so the chemicals become stable before they come to full brightness.

| CFL | WATTS | K TEMP. |

| Warm White | 13 | 2700 |

| Cool White | 13 | 4100 |

| Daylight | 13 | 6400 |

| GE | 13 | 6500 |

| Sylvania | 14 | 3000 |

| Bright Effects | 15 | 2644 |

Compact fluorescent lamps are available in many spectrums, including Daylight, Cool White, and Warm White. Compact fluorescent lamps are perfect for gardeners with a limited budget and a small space. They run cooler than HIDs and require minimal ventilation. When CFLs were first introduced, wattages were too small, and bulbs did not emit enough light to grow cannabis. The new CFLs provide enough light to grow cannabis from seed to harvest. Beware of manufacturer and reseller websites making outrageous claims about CFL performance. Add up the actual lumens and watts to verify claims.

CFL lamps that work well for gardening are available in two basic styles and shapes:

- Bulb shaped like a long “U” with a two- or four-pin fixture (these lamps are designated “1U”). The 20-inch (50.8 cm) long “1U” 55-watt, dual-pin-base bulbs are common in Europe. Normally, two 55-watt lamps are placed in a horizontal reflective hood.

- The short lamps consist of several U-shaped tubes (designated 4U, 5U, 6U, etc., for the number of U-shaped tubes) that measure approximately 8 to 12 inches (20–30 cm) not including the 2- to 4-inch (5–10 cm) attached ballast and threaded base.

Short U-shaped bulbs are most efficient when vertically oriented. When mounted horizontally under a reflective hood, much light is reflected back and forth between the bulb’s outer envelope and the hood, which markedly lowers efficiency. Heat also builds up from the ballast. Both conditions lessen efficiency.

Two Types of CFL Sockets: